Mining motors are critical components in the mining industry, powering everything from drills to conveyors. However, the harsh underground environment filled with dust and particulate matter can shorten their service life significantly. Implementing effective dust protection measures is vital to increase the longevity and maintain the performance of these mining motors. Key strategies include the integration of robust sealing systems, regular maintenance schedules, and advanced filtration technologies that prevent dust penetration. These interventions safeguard motor windings, bearings, and cooling systems from abrasive dust, reducing wear and tear and extending operational lifespan.

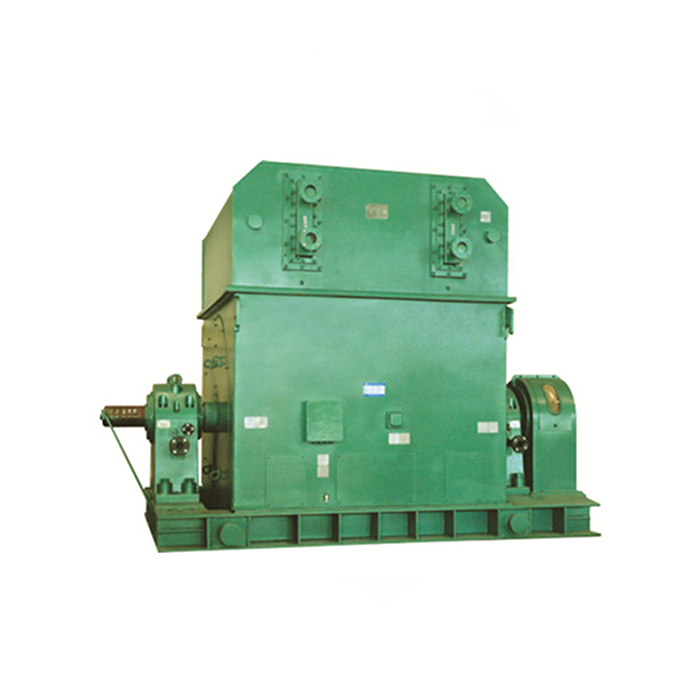

Series:T

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,

Power range:800-12000 kW

Application:fans, water pumps, compressors.

Advantage:large starting torque.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Are Mining Motors?

Mining motors refer to highly specialized electric motors engineered to function reliably in the extreme conditions typical of mining operations. Such environments often expose these motors to heavy dust, high humidity, vibration, and temperature fluctuations. Mining motors are designed with reinforced structures and unique insulation systems to handle these stresses. Their primary role is to drive large-scale equipment such as fans, water pumps, and compressors, which are essential for extraction and material processing. Incorporating robust dust protection features into these motors ensures consistent power delivery while minimizing unscheduled downtime and maintenance costs.

How Mining Motors Work

At the heart of mining electric motors lies the principle of electromagnetism, converting electrical energy into mechanical motion to power heavy machinery. In mining settings, they operate large fans that ventilate underground shafts, pumps that handle slurry and water, and compressors that maintain air pressure in pneumatic systems. The design emphasizes high starting torque to initiate movement in heavy load applications like crushers and conveyors. Case studies highlight that motors with effective dust protection outlast standard motors by multiple years, all while maintaining efficiency and reducing maintenance needs.

Benefits of Dust Protection for Mining Motors

Increased Longevity

Mining environments notoriously introduce dust particles that infiltrate motor housings, coating winding coils, bearings, and ventilation layers. This contamination accelerates abrasion, insulation degradation, and overheating, culminating in premature motor failure. Applying dust protection measures such as hermetic sealing, dust-proof enclosures, and moisture-resistant coatings effectively blocks particulate ingress. These interventions prevent damage to delicate motor internals, significantly extending service intervals and overall lifespan.

Enhanced Performance

When mining motors operate in dust-free conditions, their cooling systems function optimally, preventing temperature spikes that compromise efficiency. Reduced contamination leads to smoother bearing rotation, lowering mechanical noise and energy consumption. Over time, this translates into cost savings through decreased electricity use and fewer replacement parts. Real-world examples show that mines incorporating advanced dust protection report up to 30% longer motor life cycles and a noticeable reduction in unexpected shutdowns. These improvements enhance productivity and safety across mining operations.

Is Your Motor's Cooling System Vulnerable to Dust Ingress?

Dust ingress is a significant concern for mining motors, especially when it comes to their cooling systems. In mining environments, where dust levels are often high, the cooling system can easily become clogged or compromised. This can lead to inefficient heat dissipation, resulting in motor overheating, reduced performance, and potential damage to internal components. The accumulation of dust in the cooling system can also obstruct air vents, leading to inadequate airflow and higher operating temperatures.

To prevent these issues, it's essential to select motors equipped with sealed cooling systems and high-quality filters. Motors designed with dust-resistant features, such as IP-rated enclosures and advanced cooling mechanisms, can help protect against dust ingress. Regular maintenance and inspections are also crucial in ensuring the cooling system remains functional and free from dust buildup, prolonging the motor's lifespan and enhancing its operational reliability. By addressing these vulnerabilities, mining operations can minimize downtime and maximize productivity.

Implementing Dust Protection Measures

Best Practices for Maintenance

Routine upkeep is paramount to dust control around mining motors. Establishing scheduled cleaning regimens, including compressed air blowouts and surface wiping, prevents dust accumulation. Protective covers and seals should undergo regular inspection to detect wear or breach points that could allow dust ingress. Employing checklist-based assessments ensures systematic evaluation of dust barriers, seals, and cooling pathways. Such disciplined maintenance regimens preserve motor integrity while enabling timely repair or replacement of protective accessories, reducing unplanned downtime.

Advanced Technology Solutions

Modern innovations provide customized dust protection, including magnetic dust seals, dry air purging systems, and high-efficiency particulate air (HEPA) filters adapted for industrial motors. Customized enclosures combine reinforced insulating materials with self-draining designs to prevent moisture buildup alongside dust exclusion. CNC-machined rotors balanced to high precision minimize vibration-induced seal wear, preserving dust barriers longer. These technical advancements, when tailored to the specific environmental challenges of each mining operation, deliver superior defense against dust entry, ultimately safeguarding motor longevity and performance.

Mining Motor Suppliers and Services

When selecting mining motors and related services, partnering with experienced suppliers who understand mining environmental rigors ensures access to durable, high-performance equipment. Our company, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., stands out with a proven history of delivering robust mining motors backed by international certifications like ISO 9001:2015 and IEC Ex for explosive atmospheres. Our comprehensive range includes products rated from 800 to 12000 kW at multiple voltage levels. We prioritize customer satisfaction through prompt pre-sales consultation, expert after-sales support, and flexible bearing options (SKF, NSK, FAG) customizable to operational requirements. Testimonials from diverse mining clients affirm our commitment to quality and reliability.

Our Company Overview

Our reputation as a reliable mining motor supplier is grounded in decades of experience and a dedication to meeting stringent quality standards. Customers benefit from knowledgeable support teams well-versed in motor selection tailored to specific mining applications. Our technical expertise extends through every stage from design consultation to post-installation service. Positive customer feedback underscores our efficacy in enhancing equipment uptime and energy efficiency via state-of-the-art mining motors and dust protection measures.

Product and Service Offerings

We provide a broad portfolio of mining motors suitable for demanding environments encountered in both underground and open-pit mining. Product highlights include:

- Voltage ranges: 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, 10000V±5%

- Power capability between 800 kW and 12000 kW

- Applications covering fans, pumps, and compressors requiring significant starting torque

- Customized bearing replacement options from SKF, NSK, and FAG based on customer preference

Our product engineering incorporates features such as cast iron frames, moisture-resistant coatings on windings, and advanced cooling techniques. Support services include installation guidance, routine maintenance plans, and rapid spare parts delivery — all designed to ensure seamless operational continuity for mining clients.

Conclusion

Protecting mining motors from dust degradation is indispensable for maintaining reliable mining operations. Effective dust protection strategies extend motor longevity, enhance performance, and reduce maintenance costs. By integrating robust mechanical seals, adopting advanced filtration technologies, and committing to routine maintenance, mining enterprises can secure their equipment investment and boost productivity. Partnering with an experienced supplier like Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. ensures access to expertly engineered mining motors designed specifically to endure challenging environments while delivering exceptional power and reliability.

Frequently Asked Questions

Q1: What are the common causes of mining motor failure?

A: Mining motor failure typically results from dust accumulation that leads to insulation breakdown, overheating from poor cooling due to dust blockage, and mechanical wear of components like bearings affected by abrasive particles.

Q2: How often should mining motors be serviced for optimal performance?

A: It is advisable to service mining motors every six months. This includes thorough cleaning, inspection of protective seals, checking for wear on bearings, and verifying cooling system functionality to maintain pristine operating conditions.

Q3: What are the benefits of choosing a reputable mining motor supplier?

A: A trustworthy supplier offers access to high-quality motors built for specific mining challenges, backed by warranties and ongoing technical support. This reduces operational risk and extends equipment life, contributing to overall cost efficiency.

Where to Buy mining motor

Explore reliable mining motor options with XCMOTOR, a trusted provider specializing in durable power equipment solutions tailored to mining challenges. We offer products with voltage ranges from 3000V±5% up to 10000V±5% and power capabilities between 800 and 12000 kW, well-suited for fans, water pumps, and compressor applications with large starting torque. Contact us at xcmotors@163.com to learn how our advanced mining motors can improve your machinery's uptime and efficiency in demanding environments.

References

- IEC 60034-1: Rotating Electrical Machines – Part 1: Rating and Performance

- International Electrotechnical Commission. Guidelines on the Protection of Electric Motors in Dusty Environments. IEC TC2 Publications, 2021

- Research Article: Effects of Dust Ingress on Induction Motor Performance and Lifespan, Journal of Mining Engineering, Vol. 35, Issue 4, 2022

- Smith, J. “Maintenance Practices for Mining Motors in Abrasive Conditions,” Mining Technology Journal, 2023

- International Journal of Industrial Automation: Advances in Sealing Technology for High-Voltage Motors, 2022 Edition

- ISO 9001:2015 Quality Management Systems – Requirements and Applications in Mining Equipment Manufacturing