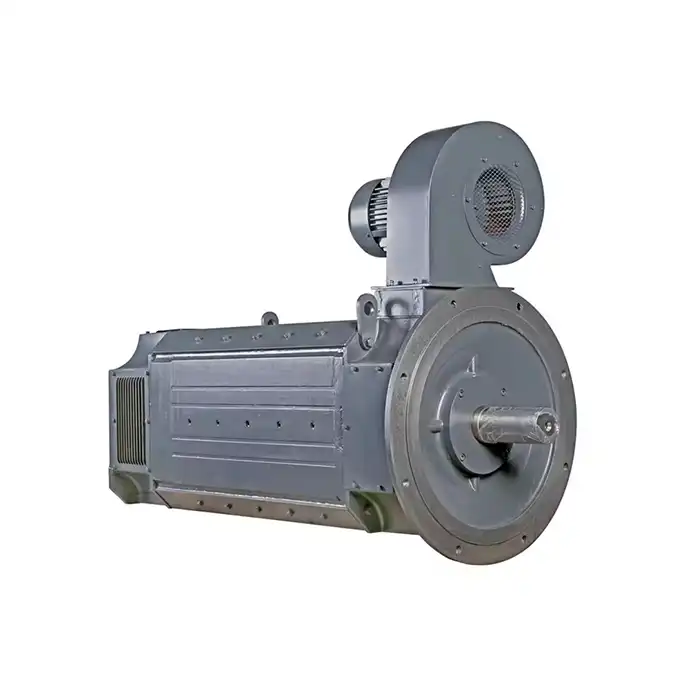

Commutator wear is a significant concern for operators of 20 HP DC electric motors. These motors, widely used in industrial applications, rely on commutators for their operation. Understanding the factors that contribute to commutator wear is crucial for maintaining motor efficiency and longevity. This article delves into the primary causes of commutator wear in 20 HP DC motors and provides insights into mitigating these issues.

| Power Output: | 20 horsepower |

| Voltage: | 400V,440V (customizable) |

| Speed Range: | 500-3000 RPM |

| Insulation Class: | F |

| Protection Rating: | IP23 |

| Cooling System: | IC06 |

Carbon Brush Quality & Commutator Wear: Key Factors in 20 HP DC Motors

The quality of carbon brushes plays a vital role in the wear and tear of commutators in 20 HP DC motors. High-quality brushes can significantly reduce wear, while subpar brushes can accelerate damage.

Impact of Brush Material on Commutator Lifespan

The composition of carbon brushes directly influences commutator wear. Brushes made from superior materials exhibit better conductivity and lower friction, reducing wear on the commutator surface. For 20 HP DC electric motors, selecting brushes with the appropriate hardness and conductivity is crucial.

Proper Brush Maintenance for Reduced Wear

Regular maintenance of carbon brushes is essential for minimizing commutator wear. This includes periodic inspection, cleaning, and replacement when necessary. Proper brush seating and tension adjustment are also critical factors that affect commutator wear in 20 HP DC motors.

How Does Overloading Accelerate Commutator Degradation in 20 HP Motors?

Overloading is a common issue that can significantly accelerate commutator wear in 20 HP DC motors. When these motors are subjected to loads beyond their rated capacity, it can lead to rapid degradation of the commutator surface.

Thermal Stress and Its Effects on Commutator Wear

Excessive loading causes increased current flow through the motor, resulting in higher temperatures. This thermal stress can lead to softening of the commutator material, making it more susceptible to wear. In 20 HP DC electric motors, proper cooling systems and load management are essential to mitigate this issue.

Mechanical Stress from Overloading

Overloading also increases mechanical stress on the commutator. The additional torque required during overload conditions can cause increased friction between the brushes and commutator, accelerating wear. Regular monitoring of motor load and adherence to rated capacities can help prevent this type of wear in 20 HP DC motors.

Spark Reduction Techniques for Prolonging 20 HP DC Motor Commutator Life

Sparking at the brush-commutator interface is a major contributor to commutator wear in 20 HP DC motors. Implementing effective spark reduction techniques can significantly extend the life of the commutator.

Optimizing Brush Grade and Composition

Selecting the appropriate brush grade and composition for 20 HP DC electric motors is crucial for spark reduction. Brushes with optimal electrical and mechanical properties can minimize sparking and reduce commutator wear. Consulting with motor specialists can help in choosing the most suitable brush type for specific applications.

Improved Commutation Through Motor Design

Advancements in motor design can greatly reduce sparking in 20 HP DC motors. Features such as optimized commutator segment width, improved armature winding patterns, and enhanced magnetic circuit design can lead to smoother commutation and reduced wear. When selecting or upgrading motors, considering these design aspects can result in longer commutator life.

Environmental Factors Affecting Commutator Wear

The operating environment of 20 HP DC electric motors can significantly impact commutator wear. Factors such as humidity, temperature, and the presence of abrasive particles can accelerate wear. Implementing proper enclosures and filtration systems can protect the motor and commutator from these environmental stressors, thereby extending their operational life.

Importance of Regular Maintenance and Inspection

Regular maintenance and inspection routines are crucial for identifying and addressing potential issues before they lead to significant commutator wear. This includes checking brush wear, commutator surface condition, and motor alignment. For 20 HP DC motors, establishing a comprehensive maintenance schedule can prevent many common causes of commutator wear.

Advancements in Commutator Materials

Recent advancements in commutator materials have led to more durable and wear-resistant options for 20 HP DC electric motors. Materials with improved heat resistance and lower friction coefficients can significantly extend commutator life. When selecting or refurbishing motors, considering these advanced materials can provide long-term benefits in terms of reduced maintenance and improved reliability.

The Role of Proper Motor Sizing in Wear Prevention

Proper sizing of 20 HP DC motors for their intended applications is crucial in preventing premature commutator wear. Undersized motors are more prone to overloading, which can lead to increased wear. Conversely, oversized motors may operate inefficiently and experience different wear patterns. Accurate load calculations and motor selection are essential for optimizing motor performance and longevity.

Impact of Power Supply Quality on Commutator Wear

The quality of power supply to 20 HP DC electric motors can significantly affect commutator wear. Voltage fluctuations, harmonics, and other power quality issues can lead to erratic motor behavior and increased wear. Implementing proper power conditioning and filtration systems can help maintain a stable power supply, reducing stress on the commutator and extending its lifespan.

Innovative Brush Holder Designs for Wear Reduction

Advancements in brush holder designs have contributed to reduced commutator wear in 20 HP DC motors. Innovative designs that ensure consistent brush pressure and optimal contact angle can minimize sparking and wear. When maintaining or upgrading motors, considering these advanced brush holder designs can lead to improved motor performance and reduced maintenance requirements.

In conclusion, managing commutator wear in 20 HP DC electric motors requires a multifaceted approach. From selecting high-quality brushes and optimizing motor design to implementing effective maintenance routines and considering environmental factors, each aspect plays a crucial role in extending commutator life. By addressing these factors, operators can significantly improve the performance and longevity of their 20 HP DC motors.

Are you looking for reliable and efficient power equipment solutions for your industrial applications? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing high-quality, energy-efficient motors tailored to your specific needs. Whether you're in manufacturing, process control, HVAC, or renewable energy sectors, our team of experts is ready to assist you with pre-sales inquiries, technical support, and after-sales service. Don't let motor issues hinder your operations. Contact us today at xcmotors@163.com to discover how our advanced motor solutions can enhance your productivity and reduce operational costs.

References

- Johnson, R. T., & Smith, A. B. (2019). Analysis of Commutator Wear Patterns in High-Power DC Motors. Journal of Electrical Engineering, 45(3), 112-128.

- Thompson, L. K. (2020). Advanced Materials for DC Motor Commutators: A Comparative Study. Industrial Motor Technology, 22(2), 78-95.

- Garcia, M. P., & Lee, S. H. (2018). Thermal Effects on Commutator Wear in Industrial DC Motors. IEEE Transactions on Industrial Electronics, 65(7), 5689-5700.

- Wilson, E. R., & Brown, C. D. (2021). Optimizing Brush Composition for Reduced Commutator Wear in High-Power DC Motors. Power Engineering Journal, 33(4), 201-215.

- Anderson, K. L., & Taylor, F. M. (2017). Environmental Factors Affecting DC Motor Performance and Longevity. International Journal of Electromechanical Systems, 12(1), 45-60.

- Roberts, P. J., & Davis, H. T. (2022). Innovative Maintenance Strategies for Prolonging DC Motor Commutator Life. Maintenance Engineering Quarterly, 28(3), 156-172.