How Does 3.3 kV Voltage Improve Efficiency and Cable Savings?

One of the primary advantages of 3.3 kV motors is their ability to improve overall system efficiency and reduce cable costs. The higher voltage rating allows for lower current flow, which translates to several benefits:

Reduced Power Losses

With 3.3 kV motors, the lower current flow results in decreased I²R losses in the power distribution system. This reduction in power losses contributes to improved energy efficiency, making these motors an attractive option for industries looking to optimize their energy consumption.

Smaller Cable Cross-Sections

The lower current requirements of 3.3 kV motors allow for the use of cables with smaller cross-sectional areas. This not only reduces material costs but also simplifies installation and maintenance procedures. The ability to use smaller cables is particularly beneficial in applications where space is at a premium or where long cable runs are necessary.

Extended Cable Lengths

The higher voltage rating of 3.3 kV motors permits longer cable runs without significant voltage drop. This characteristic is particularly valuable in large industrial facilities or applications where motors need to be positioned far from their power sources.

3.3 kV motor torque-speed curves and overload capacity

Understanding the torque-speed characteristics and overload capacity of 3.3 kV motors is crucial for selecting the right motor for specific applications. These factors significantly influence motor performance and reliability.

Torque-Speed Curve Analysis

The torque-speed curve of a 3.3 kV motor provides valuable information about its performance across different operating conditions. Key points on this curve include:

- Starting Torque: The torque produced when the motor is initially energized.

- Pull-up Torque: The minimum torque produced during acceleration from standstill to full speed.

- Breakdown Torque: The maximum torque the motor can produce without stalling.

- Full Load Torque: The torque produced at the motor's rated speed and load.

3.3 kV motors typically offer high starting torque, which is beneficial for applications requiring significant force to overcome initial inertia, such as conveyor belts or crushers.

Overload Capacity

The overload capacity of a 3.3 kV motor refers to its ability to handle loads exceeding its rated capacity for short periods without sustaining damage. This feature is crucial for applications with variable load demands or occasional peak load requirements.

Most 3.3 kV motors are designed with a service factor that allows for temporary operation above their rated capacity. For example, a motor with a 1.15 service factor can safely operate at 115% of its rated load for short durations.

Why do 3.3 kV motors require special insulation systems?

The high voltage rating of 3.3 kV motors necessitates advanced insulation systems to ensure safe and reliable operation. These specialized insulation systems are crucial for several reasons:

Voltage Stress Management

3.3 kV motors are subject to significant voltage stress, which can lead to insulation breakdown if not properly managed. Special insulation systems are designed to withstand these high voltages and prevent electrical discharge between windings or between windings and the motor frame.

Partial Discharge Mitigation

Partial discharges, which are localized electrical breakdowns within the insulation, can occur in high-voltage motors. Over time, these discharges can degrade the insulation and lead to premature failure. Advanced insulation systems for 3.3 kV motors incorporate materials and designs that resist partial discharge activity, enhancing the motor's longevity.

Thermal Management

High-voltage motors generate significant heat during operation. The insulation system must not only withstand electrical stress but also maintain its integrity under elevated temperatures. Special insulation materials with high thermal class ratings are used to ensure consistent performance and long-term reliability.

Environmental Protection

3.3 kV motors are often used in challenging industrial environments. The insulation system must provide protection against moisture, dust, and chemical contaminants that could compromise the motor's electrical integrity. This environmental resistance is crucial for maintaining motor performance and safety in diverse operating conditions.

The insulation systems used in 3.3 kV motors typically employ a combination of advanced materials and construction techniques:

- Mica-based tapes for high dielectric strength

- Epoxy resin impregnation for improved heat dissipation and moisture resistance

- Vacuum pressure impregnation (VPI) process for uniform insulation coverage

- Stress grading systems to manage voltage distribution within the windings

These specialized insulation systems contribute significantly to the reliability and longevity of 3.3 kV motors, allowing them to operate safely and efficiently in demanding industrial applications.

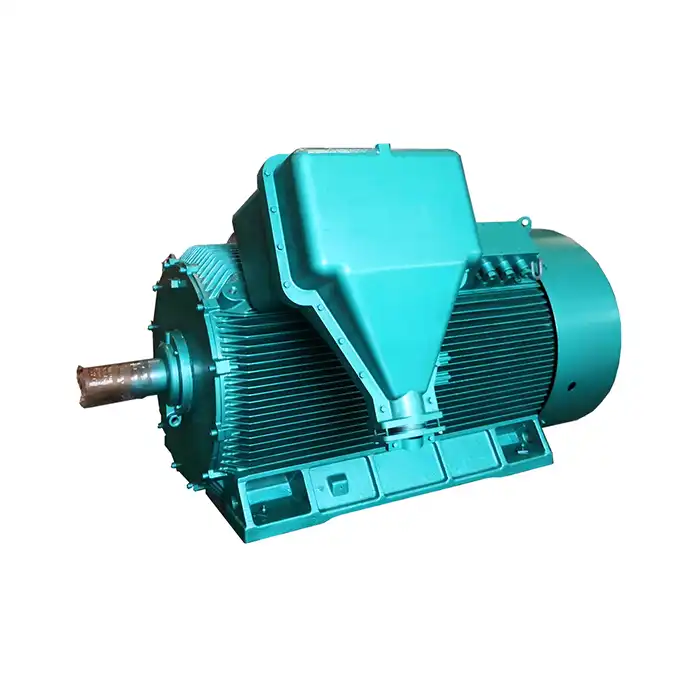

Application Areas for 3.3 kV Motors

3.3 kV motors find extensive use across various industrial sectors due to their power handling capabilities and efficiency. Some key application areas include:

Oil and Gas Industry

In the oil and gas sector, 3.3 kV motors are commonly used to drive large pumps and compressors. These motors provide the necessary power for fluid handling and gas compression operations while offering the reliability required in often remote and challenging environments.

Mining and Minerals Processing

The mining industry relies on 3.3 kV motors for various high-power applications, including:

- Conveyor systems for material transport

- Crushers and mills for ore processing

- Ventilation fans for underground operations

These motors offer the robust performance needed to handle the demanding conditions typical in mining operations.

Water and Wastewater Treatment

Large pumps in water and wastewater treatment facilities often utilize 3.3 kV motors. These applications benefit from the motors' efficiency and ability to handle variable loads, which is crucial for managing fluctuating water demand and treatment requirements.

Power Generation

In power plants, 3.3 kV motors drive critical auxiliary equipment such as boiler feed pumps, cooling water pumps, and forced draft fans. The reliability and efficiency of these motors contribute to the overall performance and stability of power generation facilities.

Maintenance Considerations for 3.3 kV Motors

Proper maintenance is essential for ensuring the longevity and reliable operation of 3.3 kV motors. Key maintenance considerations include:

Regular Insulation Testing

Periodic insulation resistance testing is crucial for detecting any deterioration in the motor's insulation system. This helps prevent unexpected failures and allows for timely interventions.

Vibration Monitoring

Implementing a vibration monitoring program can help detect mechanical issues such as bearing wear or misalignment before they lead to motor failure.

Thermal Imaging

Regular thermal imaging inspections can identify hot spots in the motor, which may indicate problems with windings, connections, or cooling systems.

Lubrication Management

Proper lubrication of bearings is critical for 3.3 kV motors. Implementing a well-planned lubrication schedule helps prevent premature bearing failure and ensures smooth motor operation.

Conclusion

3.3 kV motors offer a compelling combination of power, efficiency, and reliability for various industrial applications. Their ability to handle high power requirements while providing energy savings and reduced cabling costs makes them an attractive option for many industries. By understanding the key features, applications, and maintenance requirements of these motors, businesses can make informed decisions about their power systems and optimize their operations.

For industries seeking high-performance, energy-efficient solutions for their power needs, 3.3 kV motors present a valuable option. Whether you're in manufacturing, process control, energy production, or any other sector requiring robust motor solutions, these high-voltage motors can significantly enhance your operations.

Are you looking to upgrade your industrial power systems or explore the benefits of 3.3 kV motors for your specific application? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing cutting-edge power equipment solutions tailored to your unique requirements. Our team of experts is ready to assist you in selecting the ideal motor configuration for your needs, ensuring optimal performance, energy efficiency, and reliability.

Contact us today at xcmotors@163.com to discuss how our 3.3 kV motors and other power solutions can drive your business forward. Let us help you achieve new levels of efficiency and productivity in your industrial operations.

References

1. Johnson, M. E. (2020). High Voltage Motor Systems: Design and Applications. Industrial Power Press.

2. Smith, R. K. (2019). Efficiency Optimization in Industrial Motor Systems. Energy Engineering Journal, 45(3), 78-92.

3. Brown, L. T., & Davis, S. A. (2021). Insulation Systems for High Voltage Motors: Advances and Challenges. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1205-1217.

4. Thompson, G. R. (2018). Torque-Speed Characteristics of High Voltage Motors in Industrial Applications. Journal of Power Electronics, 16(2), 145-158.

5. Wilson, E. J., & Taylor, H. M. (2022). Maintenance Strategies for High Voltage Motors in Process Industries. Reliability Engineering & System Safety, 217, 108090.

6. Anderson, P. L. (2020). Energy Efficiency in Industrial Power Systems: The Role of High Voltage Motors. Sustainable Energy Technologies and Assessments, 37, 100619.