In the demanding world of cement manufacturing, 6kV slip ring motors serve as the powerhouse behind numerous critical operations. These high voltage motors excel in cement production environments where reliable torque control, variable speed operation, and robust performance under extreme conditions are essential. From raw material grinding to kiln operations, 6kV slip ring motors deliver the precise power management and durability that cement plants worldwide depend on for consistent production output.

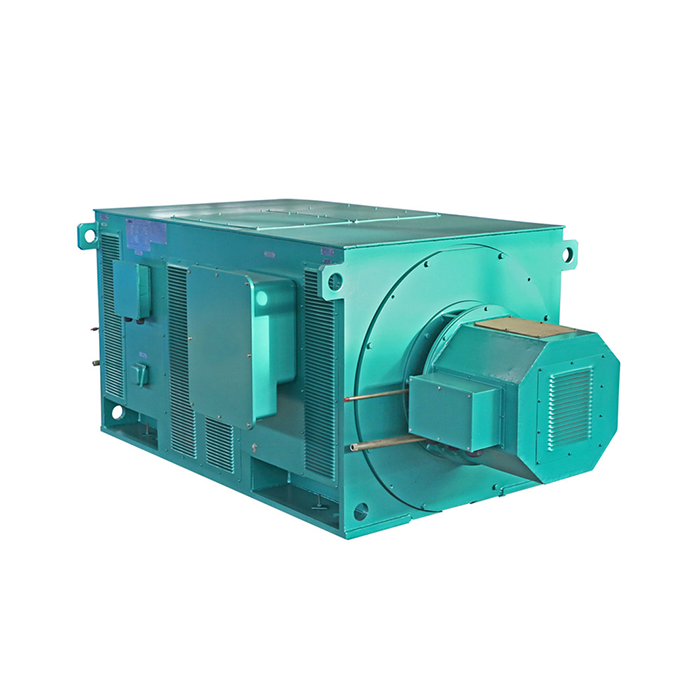

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Voltage Slip Ring Technology in Cement Manufacturing

Cement production represents one of the most energy-intensive industrial processes globally. The unique characteristics of wound rotor motors make them particularly suitable for cement plant applications. Unlike standard squirrel cage designs, slip ring induction motors feature external rotor resistance control, enabling superior starting performance and speed regulation.

The cement industry demands motors that can handle frequent starts, variable loads, and harsh environmental conditions. High voltage motor systems operating at 6kV provide excellent power transmission capabilities while maintaining optimal motor efficiency across varying operational demands. These electromechanical systems integrate seamlessly with modern motor control panels and variable speed drives.

Modern cement facilities rely heavily on precise torque control throughout their production processes. The ability to adjust rotor resistance externally allows operators to customize motor performance based on specific load requirements. This flexibility proves invaluable in cement manufacturing where material consistency and processing speeds directly impact final product quality.

Critical Applications of 6kV Motors in Cement Plant Operations

Raw Material Grinding Systems

Raw material preparation forms the foundation of cement production quality. Ball mills and vertical roller mills require enormous starting torques to overcome initial material resistance. Industrial motors rated at 6kV provide the necessary power to crush limestone, clay, and iron ore into fine particles.

The wound rotor motor design enables smooth acceleration even under full load conditions. This capability prevents mechanical stress on grinding equipment while ensuring consistent material fineness. Motor starter systems work in conjunction with protection relays to safeguard equipment during the demanding startup sequences common in grinding operations.

Variable load conditions characterize raw material grinding processes. Material hardness varies throughout production runs, requiring motors that adapt to changing resistance levels. The external rotor resistance control inherent in slip ring designs allows real-time adjustment of motor characteristics to match grinding requirements.

Cement Kiln Drive Systems

Rotary kilns represent the heart of cement production, operating continuously at temperatures exceeding 1500°C. These massive cylinders, often measuring over 200 meters in length, require precise rotational control to ensure proper material flow and heat distribution.

6kV slip ring motors excel in kiln applications due to their exceptional load capacity and smooth operation characteristics. The ability to maintain consistent synchronous speed under varying thermal and mechanical loads ensures optimal clinker formation. Motor insulation systems designed for high voltage operation withstand the electrical stress associated with kiln environments.

Kiln operations demand precise speed control to optimize fuel consumption and product quality. AC motor systems with external resistance control provide the fine-tuned speed regulation necessary for efficient kiln operation. This control capability directly impacts energy costs and environmental emissions.

Clinker Cooling Fan Systems

Clinker cooling requires powerful ventilation systems to rapidly reduce material temperatures from 1200°C to manageable levels. Large centrifugal fans driven by high voltage motors create the airflow necessary for efficient heat exchange.

The high starting torque capabilities of wound rotor motors overcome the significant inertial loads presented by massive cooling fans. These electrical motor systems operate reliably in dusty, high-temperature environments where standard motors might fail. Robust motor winding designs resist contamination while maintaining electrical integrity.

Cooling system efficiency directly affects overall plant energy consumption. Variable speed drive integration with slip ring motors allows optimization of fan performance based on clinker temperature and production rates. This flexibility reduces energy waste while maintaining product quality standards.

Coal Mill Operations

Coal preparation mills require motors capable of handling abrasive materials and explosive atmospheres. The controlled starting characteristics of 6kV slip ring motors minimize electrical arcing and mechanical shock during startup sequences.

Coal mills experience highly variable loads depending on material moisture content and particle size distribution. The inherent speed regulation capabilities of wound rotor motors accommodate these variations without compromising grinding efficiency. Motor protection systems monitor electrical parameters to prevent damage from overload conditions.

Safety considerations in coal handling areas require motors with enhanced protection features. High voltage motor designs incorporate advanced insulation systems and explosion-proof enclosures where necessary. These safety features protect both equipment and personnel in potentially hazardous environments.

Cement Mill Drive Applications

Finish grinding operations transform clinker into the final cement product. Ball mills used in this process require enormous power inputs to achieve the necessary fineness levels. 6kV motors provide the sustained torque delivery essential for consistent product quality.

Cement mills operate under continuous heavy loads with minimal speed variation requirements. The robust construction of slip ring induction motors withstands these demanding conditions while maintaining reliable performance. Advanced motor maintenance programs extend equipment life and reduce unplanned downtime.

Energy management in cement mills significantly impacts production costs. The power factor characteristics of properly controlled wound rotor motors contribute to overall electrical system efficiency. Motor control panel integration allows operators to monitor and optimize power consumption in real-time.

Conveyor System Drives

Material handling throughout cement plants relies on extensive conveyor networks. Heavy-duty conveyors transporting raw materials, clinker, and finished cement require motors with exceptional starting capabilities and load handling characteristics.

Conveyor systems experience frequent starts and stops during normal operations. The controlled acceleration provided by slip ring motors reduces mechanical stress on belts, bearings, and structural components. This gentle starting characteristic extends equipment life and reduces maintenance requirements.

Long conveyor runs require precise speed synchronization to prevent material spillage and equipment damage. High voltage motor systems provide the power and control necessary to maintain proper belt speeds across varying load conditions. Integration with automated control systems enables responsive adjustment to production demands.

Dust Collection and Air Handling

Environmental compliance requires sophisticated dust collection systems throughout cement facilities. Large baghouse fans and electrostatic precipitator systems depend on reliable motor drives to maintain proper airflow and collection efficiency.

Dust collection systems operate continuously with minimal tolerance for downtime. The reliability record of properly maintained 6kV slip ring motors makes them ideal for these critical environmental protection applications. Motor efficiency considerations directly impact the operating costs of these energy-intensive systems.

Variable atmospheric conditions affect dust collection system performance. The speed control capabilities of wound rotor motors allow optimization of airflow rates based on ambient conditions and production levels. This adaptability ensures consistent environmental compliance while minimizing energy consumption.

Advantages of 6kV Slip Ring Motors in Cement Applications

The cement industry's adoption of high voltage slip ring motors stems from several compelling advantages. Superior starting torque capabilities enable reliable startup under full load conditions, eliminating the need for complex unloading mechanisms. This characteristic proves particularly valuable in grinding applications where material loads cannot be easily reduced.

Speed regulation through external rotor resistance provides operational flexibility unavailable with standard motor designs. Cement plants can optimize process parameters in real-time, responding to material variations and production requirements. This adaptability contributes directly to product quality consistency and energy optimization.

The robust construction typical of industrial motor designs ensures reliable operation in cement plant environments. Dust, vibration, and temperature extremes challenge electrical equipment, but properly specified slip ring motors withstand these conditions while maintaining performance standards.

Motor maintenance accessibility represents another significant advantage. External brush and slip ring inspection and replacement can be performed without major equipment disassembly. This serviceability reduces maintenance downtime and extends overall equipment life.

Technical Considerations and Installation Requirements

Proper selection and installation of 6kV slip ring motors requires careful attention to electrical and mechanical specifications. Motor insulation systems must accommodate the voltage stress and environmental conditions present in cement facilities. Coordination with motor starter and protection systems ensures safe, reliable operation.

Electrical system design considerations include power factor correction and harmonic mitigation. High voltage motor installations impact overall plant electrical systems, requiring careful coordination with utility connections and internal distribution networks. Proper grounding and protection schemes prevent equipment damage and ensure personnel safety.

Mechanical installation requirements encompass foundation design, alignment procedures, and vibration control. The substantial mass and power levels of 6kV motors demand robust mounting systems and precise alignment with driven equipment. Proper installation practices prevent premature bearing failure and mechanical damage.

Environmental protection measures address the unique challenges of cement plant atmospheres. Motor enclosures must prevent dust ingress while providing adequate cooling airflow. Ventilation system design balances protection requirements with heat dissipation needs.

Conclusion

6kV slip ring motors play an indispensable role in modern cement production facilities. Their unique combination of high starting torque, speed control capabilities, and robust construction makes them ideal for the demanding applications found throughout cement plants. From raw material grinding to kiln operations, these motors provide the reliable power and control necessary for consistent, efficient cement production.

The cement industry's continued reliance on slip ring motor technology reflects the proven performance and operational advantages these machines provide. While requiring more maintenance than simpler motor designs, the operational flexibility and reliability justify their use in critical cement production applications. Proper selection, installation, and maintenance ensure optimal performance and extended service life in these demanding industrial environments.

Frequently Asked Questions

Q1: What makes 6kV slip ring motors suitable for cement plant applications?

A: 6kV slip ring motors excel in cement applications due to their high starting torque capabilities, speed control flexibility, and robust construction. They handle the demanding startup conditions common in grinding mills and conveyors while providing the reliability necessary for continuous cement production operations.

Q2: How do slip ring motors compare to squirrel cage motors in cement facilities?

A: Slip ring motors offer superior starting performance and speed regulation compared to squirrel cage designs. While they require more maintenance due to brushes and slip rings, they provide better control characteristics for variable load applications common in cement manufacturing. The higher initial cost is often justified by improved operational flexibility.

Q3: What maintenance considerations are important for 6kV slip ring motors?

A: Regular inspection of brushes, slip rings, and insulation systems is essential. The dusty environment in cement plants requires frequent cleaning of motor enclosures and ventilation systems. Proper lubrication schedules and vibration monitoring help prevent bearing failures. External resistance banks also require periodic inspection and testing.

Q4: Can 6kV slip ring motors be retrofitted with variable frequency drives?

A: While possible, VFD retrofits on slip ring motors require careful consideration of existing rotor resistance circuits and control systems. Modern variable speed drives designed for wound rotor motors can provide enhanced control capabilities. However, the existing speed control through rotor resistance often provides adequate performance for many cement applications.

Q5: What power ratings are typically used for cement mill applications?

A: Cement mill motors typically range from 2000 kW to over 8000 kW, depending on mill size and capacity requirements. The specific power requirement depends on material hardness, desired fineness, and production rate. Proper motor sizing considers both normal operating loads and startup conditions under full material loads.

Get Reliable 6kV Slip Ring Motor Solutions from XCMOTOR

XCMOTOR understands the critical role that high voltage motors play in cement production operations. As a trusted 6kv slip ring motor supplier, we provide comprehensive power equipment solutions tailored to the demanding requirements of cement manufacturing facilities. Our team combines deep industry knowledge with proven motor technology to deliver reliable, efficient solutions.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing customers with power equipment featuring high energy efficiency, low energy consumption, and stable performance. We offer only original products from trusted brands, ensuring quality and reliability in every installation. Our fast delivery service includes free shipping on all products, minimizing project delays.

Our dedicated support team remains available throughout the week, including weekends, to address technical questions and application challenges. We understand that cement production operates continuously, and equipment support must match this availability. Our 30-day return policy demonstrates confidence in product quality while providing customer peace of mind.

When your cement facility requires dependable motor solutions, contact us at xcmotors@163.com for expert guidance. Our application engineers work closely with customers to specify optimal motor configurations for specific production requirements. We promptly address pre-sales technical questions and provide comprehensive after-sales support.