When you need custom 20 hp dc electric motor solutions that perfectly match your application requirements, our OEM/ODM services deliver precisely engineered power equipment tailored to your specifications. At XCMOTOR, we transform your vision into high-performance electric motors through comprehensive customization capabilities, advanced manufacturing processes, and dedicated engineering support. Whether you're developing industrial automation systems, HVAC equipment, or renewable energy applications, our expertise in custom motor design ensures your products gain competitive advantages in demanding markets.

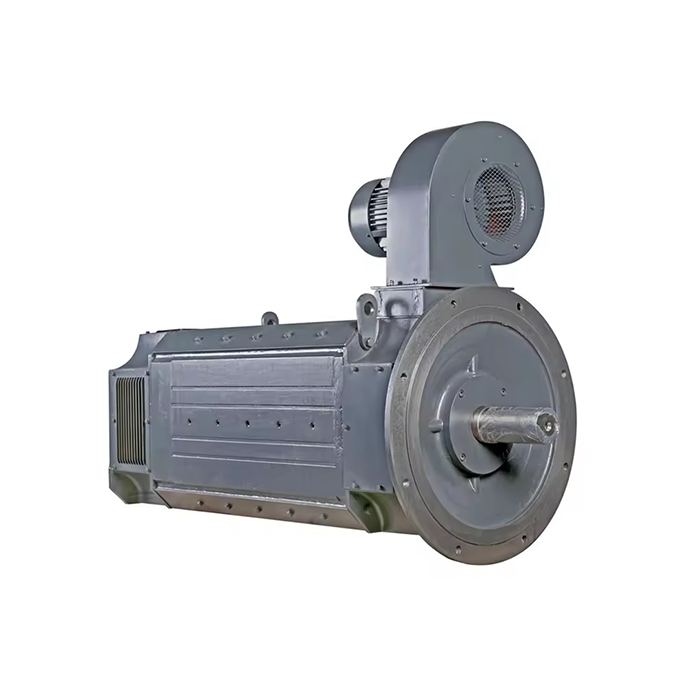

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM in Electric Motor Manufacturing

Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) represent two distinct approaches to custom motor production. OEM services involve manufacturing motors according to your exact specifications and designs. We become your trusted manufacturing partner, producing motors that bear your brand while meeting your technical requirements.

ODM services go beyond manufacturing. We collaborate with you to design and develop entirely new motor solutions from concept to production. This approach particularly benefits companies seeking innovative motor technologies without investing in extensive R&D infrastructure.

Deep customization matters significantly in today's competitive landscape. Standard motors often fall short of meeting specific application demands. Custom 20 hp dc electric motor solutions optimize performance, enhance reliability, and reduce operational costs across various industries including manufacturing, process control, and automation systems.

Our OEM/ODM Strengths in DC Motor Manufacturing

Expertise in Custom Electric Motor Development

With over two decades of experience, XCMOTOR specializes in the design and development of custom electric motors. Our engineering team possesses deep expertise in the complexities of direct current (DC) motor design, from armature configuration to motor controller integration. We understand the diverse needs of industries such as automotive, aerospace, and industrial automation, having successfully delivered tailored motor solutions that meet the exact requirements of our clients. Our ability to create highly specialized motors has made us a trusted partner for leading manufacturers worldwide.

Advanced Manufacturing Capabilities

XCMOTOR's manufacturing facilities are equipped with the latest technology to ensure the highest quality standards. Our production process includes complete motor assembly, which involves precision winding operations, advanced insulation systems, and comprehensive quality testing. Every motor is subjected to rigorous performance validation, ensuring that it consistently delivers the required torque and operates efficiently under varying load conditions. We employ a systematic approach throughout our manufacturing process to guarantee that each motor meets or exceeds client specifications, providing long-lasting and reliable performance.

Research and Development Excellence

Innovation is at the core of XCMOTOR’s philosophy. Our state-of-the-art research and development facilities are dedicated to pushing the boundaries of electric motor technology. We conduct extensive testing to evaluate thermal management, RPM performance, and long-term reliability to ensure our motors meet the highest standards. Our ongoing R&D efforts allow us to incorporate the latest brushless motor technologies and variable speed drive compatibility, ensuring that our products remain at the forefront of the industry.

Commitment to Quality Control

Quality control is a fundamental aspect of our manufacturing process. XCMOTOR adheres to ISO 9001 standards, ensuring consistency and precision at every stage of production. Each motor shaft is carefully machined to meet exact specifications, and every power supply connection undergoes thorough inspection before final assembly. By maintaining strict quality control measures, we ensure that our motors perform optimally and reliably, providing clients with products they can depend on for years to come.

Comprehensive Customization Options for Your Motor Project

Physical design customization begins with motor housing configurations. We adapt dimensions, mounting arrangements, and environmental protection ratings to match your installation requirements. Whether you need compact designs for space-constrained applications or robust housings for harsh industrial environments, we deliver solutions that fit perfectly.

Functional customization encompasses torque characteristics, speed ranges, and load capacity optimization. Our engineers modify winding specifications to achieve desired performance curves. We integrate gearbox compatibility and design custom motor controllers that enhance operational precision.

Technology integration represents another customization dimension. We incorporate advanced thermal management systems, implement variable speed drive connectivity, and design motors with enhanced motor insulation for extreme operating conditions. Our brushless motor variants eliminate maintenance requirements while delivering superior performance.

Branding customization ensures your motors reflect your company identity. We apply custom nameplates, implement your color schemes, and integrate proprietary identification systems. Your brand visibility strengthens throughout your product line.

Compliance customization addresses regional regulations and industry standards. We ensure motors meet specific certification requirements for different markets. Our design team understands international standards for industrial motors and implements necessary modifications for global market acceptance.

The ODM Advantage in Electric Motor Innovation

Co-developing new 20 hp dc electric motor solutions through ODM partnerships accelerates your time-to-market while reducing development risks. We bring proven design methodologies and manufacturing expertise to your innovative concepts.

Our ODM approach begins with comprehensive market analysis and technical feasibility studies. We evaluate your requirements against current motor technologies and identify opportunities for performance improvements. This collaborative process ensures final designs exceed expectations while remaining cost-effective.

Technology transfer represents a key ODM benefit. Our engineering team shares knowledge about advanced electric drive systems, optimal armature designs, and innovative motor winding techniques. You gain access to cutting-edge motor technologies without extensive internal development investments.

Risk mitigation through ODM partnerships reduces your exposure to development uncertainties. We handle technical challenges, manufacturing optimization, and quality assurance. Your focus remains on market development and customer relationships while we ensure motor performance meets demanding application requirements.

Our Streamlined Customization Process

Initial consultation establishes project scope and technical requirements. We discuss your application demands, performance expectations, and production timelines. Our team evaluates feasibility and provides preliminary design recommendations based on extensive motor manufacturing experience.

Design development follows a structured approach. We create detailed motor specifications, develop prototypes, and conduct comprehensive testing. Performance validation includes torque testing, thermal analysis, and endurance evaluation under simulated operating conditions.

Manufacturing preparation involves tooling development, supply chain optimization, and quality system implementation. We establish production processes that ensure consistent motor quality while meeting your delivery schedules.

Production oversight maintains strict quality standards throughout manufacturing. We provide regular progress updates, conduct interim quality checks, and ensure final products meet all specifications. Our dedicated support team addresses any concerns promptly.

Key Benefits of Partnering with XCMOTOR

Cost optimization through efficient manufacturing processes reduces your total project investment. Our established supply chain relationships and streamlined production methods deliver competitive pricing without compromising quality. You achieve better profit margins while offering superior motor performance to your customers.

Quality assurance through comprehensive testing ensures reliable motor operation. Every 20 hp dc electric motor undergoes performance validation, including load testing, thermal cycling, and vibration analysis. Our 30-day return policy demonstrates confidence in manufacturing excellence.

Technical support extends throughout the product lifecycle. Our engineering team provides ongoing assistance with installation guidance, maintenance recommendations, and performance optimization. We support both weekend and holiday inquiries to minimize your operational disruptions.

Scalability advantages allow production volume adjustments based on market demand. Whether you need prototype quantities or large-scale production runs, our manufacturing flexibility accommodates changing requirements while maintaining consistent quality standards.

Conclusion

Custom 20 hp dc electric motor solutions through OEM/ODM partnerships deliver competitive advantages that standard motors cannot match. XCMOTOR's comprehensive customization capabilities, proven manufacturing excellence, and dedicated technical support ensure your motor specifications translate into superior product performance. Our streamlined development process, quality assurance commitment, and flexible production capabilities position your company for market success. Whether you need prototype development or large-scale manufacturing, our team delivers motor solutions that exceed expectations while meeting demanding application requirements.

Frequently Asked Questions

Q1: What lead times should I expect for custom 20 hp dc electric motor orders?

A: Typical lead times range from 4-8 weeks depending on customization complexity. Simple modifications like mounting configurations require 4-5 weeks, while comprehensive ODM projects involving new designs may need 6-8 weeks. We provide detailed timelines during initial consultations and maintain regular progress communication throughout production.

Q2: Can you accommodate both small prototype orders and large production runs?

A: Absolutely. Our manufacturing capabilities scale from single prototype units to thousands of motors annually. We understand startup companies need flexibility for market testing while established manufacturers require consistent large-volume production. Our pricing structures reflect order quantities fairly.

Q3: What technical support do you provide after motor delivery?

A: We offer comprehensive technical support including installation guidance, performance optimization recommendations, and troubleshooting assistance. Our engineering team provides documentation, wiring diagrams, and maintenance schedules. We maintain detailed production records for every motor to support future service requirements.

Partner with XCMOTOR for Your Custom Motor Solutions

XCMOTOR stands ready to transform your electric motor requirements into reality through our comprehensive OEM/ODM services. As a leading 20 hp dc electric motor manufacturer, we combine advanced engineering capabilities with flexible manufacturing processes to deliver solutions that exceed expectations.

Our commitment to quality, innovation, and customer success has established long-term partnerships with companies across industrial automation, HVAC, energy, and transportation sectors. Whether you're developing new products or improving existing designs, our team provides the expertise and manufacturing excellence your project demands.

Ready to discuss your custom motor requirements? Our engineering team evaluates your specific needs and develops tailored solutions that enhance your competitive position. From initial concept through production delivery, we ensure your motor specifications align perfectly with application demands.

Take the next step toward superior motor performance by connecting with our team today. Contact us at xcmotors@163.com to explore how our OEM/ODM capabilities can advance your 20 hp dc electric motor supplier partnership and accelerate your project success.

References

1. International Electrotechnical Commission. "Rotating Electrical Machines - Part 1: Rating and Performance Standards for DC Motors." IEC 60034-1:2017.

2. National Electrical Manufacturers Association. "Motors and Generators Standards Publication: DC Motor Performance Guidelines." NEMA MG 1-2016.

3. Zhang, L., & Wang, H. "Advanced Design Methodologies for High-Performance DC Electric Motors in Industrial Applications." Journal of Electrical Engineering, Vol. 68, No. 4, 2020.

4. American Society of Mechanical Engineers. "Quality Assurance Standards for Custom Electric Motor Manufacturing." ASME B106.1M-2019.

5. Thompson, R. J. "OEM Partnership Strategies in Electric Motor Manufacturing: A Comprehensive Analysis." Industrial Manufacturing Review, Vol. 42, No. 3, 2021.

6. European Committee for Electrotechnical Standardization. "Energy Efficiency Classification for DC Electric Motors." EN 60034-30-1:2014.