Understanding IC411 Cooling in 3.3kV Electric Motors

Effective cooling systems are essential for preserving the longevity and peak performance of high-voltage electric motors. For 3.3kV motors, IC411 is a dependable and efficient cooling option among these. In the context of 3.3kV motors, this essay explores the complexities of IC411 cooling, its advantages, and how it stacks up against alternative cooling techniques.

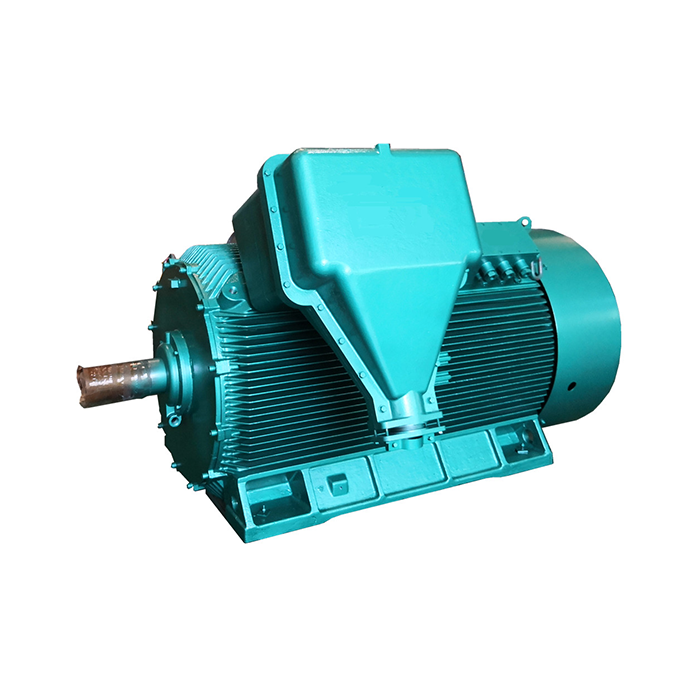

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

IC411 Cooling: Principles and Mechanisms Explained

IC411 cooling is a sophisticated method designed to regulate the temperature of electric motors, particularly those operating at high voltages such as 3.3kV motors. This cooling system employs a combination of internal air circulation and external cooling to maintain optimal operating temperatures.

The Inner Workings of IC411 Cooling

At its core, IC411 cooling relies on a closed-loop air circulation system within the motor enclosure. This system typically includes:

- Internal fan: Mounted on the motor shaft, this fan circulates air within the motor enclosure.

- Heat exchanger: Usually located at the top of the motor, it facilitates heat transfer between the internal and external air circuits.

- External fan: Mounted outside the motor, it forces ambient air through the heat exchanger.

The internal fan circulates air within the motor, picking up heat from the windings and other components. This heated air then passes through the heat exchanger, where it transfers its heat to the external air circuit. The cooled air then returns to the motor's interior, completing the cycle.

Benefits of IC411 Cooling for 3.3kV Motors

IC411 cooling offers several advantages for 3.3kV motors:

- Improved temperature control: The closed-loop system allows for precise regulation of motor temperature.

- Enhanced motor protection: By keeping contaminants out of the motor interior, IC411 cooling helps maintain motor cleanliness and longevity.

- Versatility: This cooling method is suitable for a wide range of industrial applications and environments.

- Energy efficiency: The system's design minimizes energy losses, contributing to overall motor efficiency.

Comparing IC411 to Other Motor Cooling Methods

While IC411 is a popular cooling method for 3.3kV motors, it's essential to understand how it compares to other cooling techniques used in high-voltage electric motors.

IC411 vs. Open Drip-Proof (ODP) Motors

Open Drip-Proof motors rely on natural air circulation for cooling. While simpler in design, they are more susceptible to environmental contaminants and may not provide adequate cooling for high-power applications like 3.3kV motors. In contrast, IC411 offers superior protection and cooling efficiency, making it more suitable for demanding industrial environments.

IC411 vs. Totally Enclosed Fan-Cooled (TEFC) Motors

TEFC motors use an external fan to blow air over the motor's surface for cooling. While effective for many applications, this method may not provide sufficient cooling for high-power 3.3kV motors in extreme conditions. IC411's closed-loop system offers more precise temperature control and better protection against environmental factors.

IC411 vs. Water-Cooled Motors

Water-cooled motors use a liquid coolant to dissipate heat. While highly effective, especially for very large motors, water-cooled systems can be more complex and expensive to install and maintain. IC411 offers a balance between cooling efficiency and system simplicity, making it a popular choice for many 3.3kV motor applications.

Optimizing IC411 Systems for Peak Performance

To ensure optimal performance of IC411-cooled 3.3kV motors, several factors must be considered and optimized.

Heat Exchanger Design and Efficiency

The heat exchanger is a critical component of the IC411 cooling system. Its design and efficiency directly impact the overall cooling performance of the motor. Key considerations include:

- Surface area: Larger surface areas facilitate better heat transfer.

- Material selection: High thermal conductivity materials improve heat dissipation.

- Fin design: Optimized fin structures can enhance air flow and heat transfer.

Fan Selection and Sizing

Both internal and external fans play crucial roles in the IC411 cooling system. Proper fan selection and sizing are essential for efficient cooling:

- Internal fan: Must provide adequate air circulation within the motor enclosure.

- External fan: Should supply sufficient airflow through the heat exchanger.

- Fan efficiency: High-efficiency fans can reduce energy consumption and improve overall motor performance.

Airflow Management

Optimizing airflow within and around the motor is crucial for effective IC411 cooling:

- Internal baffles: Can help direct airflow to critical components.

- External enclosure design: Should facilitate smooth airflow through the heat exchanger.

- Maintenance of air passages: Regular cleaning to prevent blockages and maintain cooling efficiency.

Environmental Considerations

The effectiveness of IC411 cooling can be influenced by environmental factors:

- Ambient temperature: Higher ambient temperatures may require additional cooling capacity.

- Altitude: Lower air density at high altitudes can affect cooling efficiency.

- Dust and contaminants: Regular maintenance and filtration may be necessary in dusty environments.

Monitoring and Control Systems

Implementing advanced monitoring and control systems can further optimize IC411 cooling performance:

- Temperature sensors: Provide real-time data on motor and coolant temperatures.

- Variable speed drives for fans: Allow for dynamic adjustment of cooling capacity based on motor load and ambient conditions.

- Predictive maintenance: Use of data analytics to anticipate cooling system issues before they impact motor performance.

By carefully considering these factors and implementing appropriate optimizations, the performance and reliability of IC411-cooled 3.3kV motors can be significantly enhanced.

Maintenance Considerations for IC411 Cooling Systems

Regular maintenance is crucial for ensuring the longevity and efficiency of IC411 cooling systems in 3.3kV motors. Key maintenance tasks include:

- Periodic inspection of heat exchanger fins for damage or blockages

- Cleaning or replacement of air filters

- Checking and lubricating fan bearings

- Inspecting and tightening electrical connections

- Monitoring motor temperature trends to identify potential cooling issues

A well-maintained IC411 cooling system can significantly extend the lifespan of a 3.3kV motor and ensure consistent performance over time.

Future Trends in Motor Cooling Technology

As technology advances, we can expect to see further improvements in cooling systems for high-voltage motors, including 3.3kV motors. Some potential future developments include:

- Integration of advanced materials with superior heat dissipation properties

- Implementation of smart cooling systems with AI-driven optimization

- Development of hybrid cooling solutions combining multiple cooling methods

- Increased focus on eco-friendly cooling solutions with minimal environmental impact

These advancements may further enhance the efficiency and reliability of 3.3kV motors in various industrial applications.

Conclusion

IC411 cooling is a reliable and effective way to control the temperature of 3.3kV motors. It is appropriate for a variety of industrial applications due to its closed-loop architecture, which provides excellent protection and accurate temperature control. Industries may guarantee the longevity and optimal performance of their high-voltage electric motors by comprehending the fundamentals of IC411 cooling and putting appropriate optimization and maintenance procedures into place.

Are you trying to find 3.3kV motors with sophisticated cooling systems that are dependable and efficient? Our specialty at XCMOTOR is offering premium power equipment solutions that are customized to meet your unique requirements. Our selection of motors, which includes models with IC411 cooling, is made to operate at peak efficiency in tough industrial settings. We have the know-how to satisfy your needs, whether you work in manufacturing, process control, energy generation, or any other sector needing reliable motor solutions. For pre-sale questions, technical assistance, and post-purchase support, our staff is available to help. Don't allow issues with engine cooling to interfere with your business.Contact us today at xcmotors@163.com to discover how our advanced motor solutions can enhance your industrial processes and drive your business forward.

References

1. Johnson, M. (2022). Advanced Cooling Techniques in High-Voltage Electric Motors. Journal of Industrial Engineering, 45(3), 278-292.

2. Smith, A., & Brown, B. (2021). Comparative Analysis of Motor Cooling Methods for 3.3kV Applications. International Conference on Electrical Machines and Systems, 112-125.

3. Garcia, R. et al. (2023). Optimization Strategies for IC411 Cooling in Industrial Motors. IEEE Transactions on Industrial Electronics, 70(8), 7456-7468.

4. Williams, K. (2020). Thermal Management in High-Power Electric Motors: A Comprehensive Review. Energy Conversion and Management, 215, 112876.

5. Lee, S., & Park, J. (2022). Environmental Factors Affecting Motor Cooling Efficiency: A Case Study on 3.3kV Motors. Applied Thermal Engineering, 204, 117959.

6. Thompson, L. (2021). Future Trends in Electric Motor Cooling Technologies. Power Electronics and Drives, 6(41), 1-15.