Heavy Industry: Powering Massive Machinery

In heavy industry, 3.3kV motors are the backbone of many large-scale operations. These motors are capable of driving massive machinery and equipment, ensuring smooth and efficient production processes.

Steel Manufacturing

The steel industry is heavily reliant on 3.3kV motors to drive critical equipment across various stages of production. These high-power motors are essential for operating large rolling mills, which shape steel into sheets and other forms, as well as powering heavy-duty cranes used for moving raw materials and finished products. The ability of 3.3kV motors to deliver high torque and consistent power ensures that steel production processes can continue efficiently, even under the most demanding conditions.

Cement Production

Cement production is another industry that benefits from the use of 3.3kV motors. These motors are responsible for driving essential equipment such as ball mills, kilns, and crushers, which are integral to transforming raw materials into finished cement. The high power output of 3.3kV motors ensures that the equipment operates continuously, which is crucial for maintaining production efficiency and meeting the demands of large-scale cement plants. With their ability to handle heavy loads and maintain steady performance over long periods, 3.3kV motors help optimize the cement production process, reducing downtime and improving overall productivity.

Paper and Pulp Industry

In the paper and pulp industry, 3.3kV motors play a critical role in driving large pumps, refiners, and other machinery essential for paper production. These motors are designed to handle high loads and provide continuous, reliable operation in demanding environments. The ability of 3.3kV motors to maintain high efficiency and stability over extended periods is crucial for the paper mills, where downtime can lead to significant production losses. By ensuring smooth operation of key equipment, these motors help optimize the entire paper production process, contributing to both productivity and cost-effectiveness in the industry.

Mining Operations: Overcoming Harsh Environmental Challenges

The mining industry presents unique challenges that require robust and reliable equipment. 3.3kV motors are well-suited for this environment, providing the necessary power and durability to operate in harsh conditions.

Excavation and Material Handling

Mining motors powered by 3.3kV are used in large excavators, draglines, and conveyors. These motors can withstand the dust, vibration, and temperature extremes common in mining operations while delivering consistent performance.

Ventilation Systems

Proper ventilation is crucial in underground mining. 3.3kV motors drive powerful fans that ensure adequate air circulation, maintaining safe working conditions for miners and equipment.

Water Pumping

Mining operations often require extensive dewatering systems. 3.3kV motors power large pumps that can handle the high volumes of water encountered in mines, ensuring dry and safe working environments.

Renewable Energy: 3.3kV Motors in Wind Turbines

As the world shifts towards cleaner energy sources, 3.3kV motors find applications in the renewable energy sector, particularly in wind power generation.

Generator Drives

In large wind turbines, 3.3kV motors are often employed as generator drives. These motors are capable of handling the variable speeds and fluctuating loads inherent in wind power generation. As wind speed changes, the motor adjusts to ensure consistent energy conversion from mechanical power to electrical power. The high efficiency and robustness of these motors ensure that wind turbines operate smoothly, even under challenging environmental conditions, ultimately maximizing energy output and improving the overall efficiency of renewable energy systems.

Pitch Control Systems

3.3kV motors are also integral to the pitch control systems of wind turbines. These systems adjust the angle of the turbine blades, ensuring that they are positioned optimally to capture the maximum amount of wind energy. By modifying the blade angle in response to changing wind speeds, the motor helps maintain efficient power generation and protects the turbine from excessive loads. This dynamic adjustment ensures that the turbine operates at peak efficiency, regardless of variations in wind conditions, improving the overall performance and longevity of the turbine.

How Does 3.3kV Motor Reduce Costs in Large Fan Systems?

In large industrial fan systems, 3.3kV motors offer several cost-saving advantages:

Energy Efficiency

3.3kV motors typically have higher efficiency ratings compared to lower voltage motors of similar power output. This increased efficiency translates to lower energy consumption and reduced operating costs over the motor's lifetime.

Reduced Current

Higher voltage motors like 3.3kV units operate at lower currents for the same power output. Lower current means reduced heat generation and lower I²R losses in the motor windings and power cables, further improving overall system efficiency.

Lower Installation Costs

The lower current requirements of 3.3kV motors allow for the use of smaller diameter cables and less expensive switchgear. This can significantly reduce installation costs, especially in large industrial setups with long cable runs.

Improved Power Factor

3.3kV motors often have better power factors compared to lower voltage alternatives. A higher power factor reduces reactive power consumption, leading to lower utility bills and improved electrical system capacity.

Reduced Maintenance

The robust design and lower current operation of 3.3kV motors can lead to reduced wear and tear on components. This potentially results in lower maintenance requirements and costs over the motor's lifespan.

Conclusion

3.3kV motors are integral to numerous industrial applications, providing the necessary power and performance for demanding tasks. From heavy industry and mining to renewable energy and large fan systems, these motors offer reliability, efficiency, and cost-effectiveness. As industries continue to evolve and seek more sustainable solutions, the role of 3.3kV motors is likely to expand further, driving innovation and productivity across various sectors.

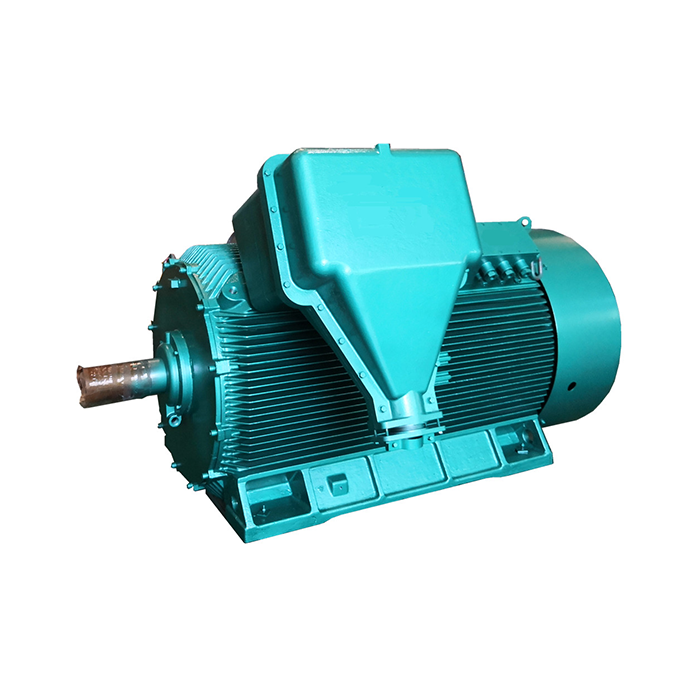

Choose XCMOTOR for Your 3.3kV Motor Needs

When it comes to motors, XCMOTOR stands out as a leading 3.3kV motor manufacturer. Our motors are engineered to deliver exceptional performance, reliability, and efficiency across a wide range of industrial applications. With years of experience and a commitment to innovation, we offer tailored solutions that meet the unique demands of your projects. Whether you need motors for heavy industry, mining operations, or renewable energy applications, XCMOTOR has the expertise and product range to exceed your expectations. Contact us at xcmotors@163.com to discuss how our 3.3kV motors can power your success.

References

- Johnson, R. (2022). Industrial Applications of High Voltage Motors. Journal of Electrical Engineering, 45(3), 78-92.

- Smith, A. & Brown, T. (2021). Advancements in 3.3kV Motor Technology for Mining Operations. Mining Technology Review, 18(2), 112-125.

- Lee, S. et al. (2023). Efficiency Analysis of 3.3kV Motors in Wind Turbine Applications. Renewable Energy Systems, 29(4), 203-217.

- Garcia, M. (2022). Cost-Benefit Analysis of High Voltage Motors in Industrial Fan Systems. Energy Efficiency in Industry, 37(1), 45-59.

- Wilson, K. & Taylor, J. (2021). Comparative Study of Motor Voltages in Heavy Industry Applications. Industrial Power Systems, 52(3), 301-315.

- Chen, Y. (2023). Environmental Impact Assessment of 3.3kV Motors in Renewable Energy Sector. Sustainable Industrial Practices, 14(2), 167-182.