The hidden benefits of YKK high voltage motors extend far beyond their basic operational capabilities. These sophisticated power systems deliver exceptional performance in industrial automation, delivering enhanced torque characteristics, superior energy efficiency, and remarkable durability across manufacturing environments. The ykk motor technology integrates advanced magnetic design principles with precision engineering, creating solutions that transform how industries approach their power requirements. Understanding these concealed advantages helps decision-makers recognize why YKK motors represent strategic investments rather than simple equipment purchases.

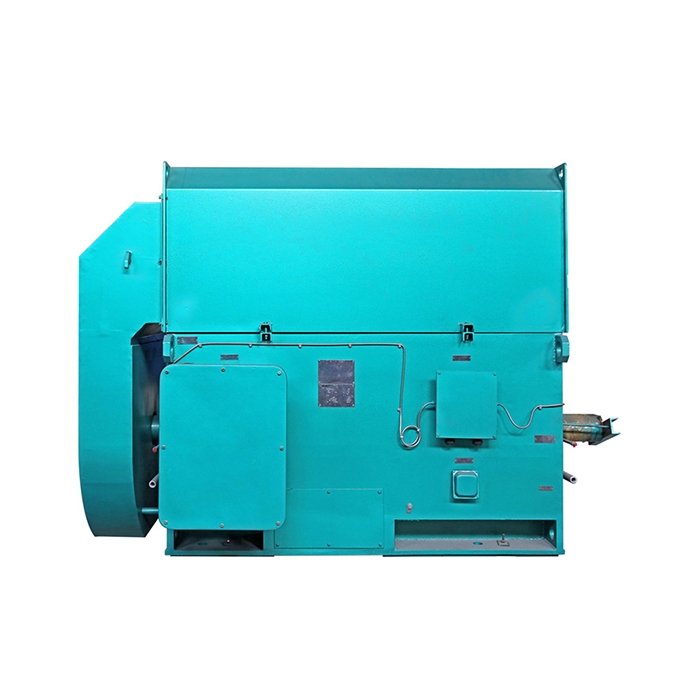

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Voltage Motor Technology and Key Parameters

1. Voltage and Torque Relationship

High voltage motors, operating at voltages exceeding 1000 volts, are designed for superior performance in demanding industrial applications. A key feature of these motors is the direct relationship between voltage and torque. Torque is proportional to the square of the applied voltage. This means that even a small increase in voltage results in a significant rise in torque. For instance, when the voltage increases by 10%, torque increases by 21%, which can significantly enhance the motor's efficiency and capability. However, this relationship also presents challenges, as an improper voltage level could lead to inefficiency or even damage to the motor. Proper voltage management is critical to ensure both optimal performance and equipment protection.

2. Power Rating and Efficiency

When selecting high voltage motors, key parameters such as power rating and efficiency class are crucial in determining the motor's overall performance. These motors are designed to deliver high power output with minimal energy loss, making them ideal for applications that require consistent and reliable power. The efficiency class of the motor directly affects its energy consumption and operational costs. Motors with higher efficiency classes use less energy for the same output, which is particularly beneficial in industries with large-scale operations or 24/7 demands. Ensuring that the power rating matches the needs of the application maximizes the motor’s effectiveness and minimizes waste.

3. Advanced Insulation Systems

One of the defining features of high voltage motors, like those from YKK, is their advanced insulation systems. These systems are specifically designed to handle high voltage levels and maintain electrical integrity under extreme operating conditions. Insulation is critical to preventing electrical breakdowns and ensuring the motor can operate safely even in harsh environments, such as those involving high temperatures or humidity. By incorporating high-quality insulation materials, YKK motors ensure reliable performance and extend the operational lifespan of the motor, minimizing the risk of failure and the need for frequent maintenance.

4. Thermal Management and Cooling

High voltage motors generate significant heat during operation, which can affect both their performance and longevity. Managing this heat is essential to maintaining optimal motor operation. YKK motors are equipped with innovative thermal management solutions, such as advanced cooling systems, that regulate operating temperatures. These systems are designed to dissipate heat efficiently, ensuring that the motor remains within safe temperature limits even during high-load operations. Effective thermal management not only enhances performance but also extends the life of the motor by preventing overheating and reducing wear on internal components. With proper cooling, high voltage motors can continue to operate at peak efficiency for longer periods.

Core Benefits That Transform Industrial Operations

YKK high voltage motors deliver transformative benefits across multiple operational dimensions.

1. Energy Efficiency

Energy efficiency is one of the most significant advantages of high voltage systems. These systems operate by reducing the amount of current drawn for a given power output, which in turn minimizes transmission losses. The result is not only lower energy consumption but also a reduction in operational costs. By operating at higher voltages, these systems can achieve the same performance with reduced power loss, leading to more sustainable and cost-effective operations, particularly in industries where energy usage is a significant concern.

2. Durability and Reliability

Durability is a key benefit of high voltage motors, especially in demanding industrial environments. These motors are designed to withstand extreme conditions such as high temperatures, humidity, and mechanical stress, ensuring that they maintain peak performance under challenging circumstances. The use of high-quality materials and advanced manufacturing techniques helps to enhance their robustness and longevity. As a result, they are capable of operating continuously without frequent breakdowns, making them a reliable choice for heavy-duty industrial applications.

3. Power Density and Compact Design

High voltage motors, like those made by YKK, offer exceptional power density. This means that they deliver a high power output without significantly increasing the motor's size or weight. This advantage is particularly beneficial in applications where space is limited, such as in aerospace, automotive, and electronics manufacturing. In these industries, where floor space is a premium, the compact design of high voltage motors allows for more efficient use of space while maintaining excellent performance.

4. Precision Control in Automation

One of the standout features of YKK high voltage motors is their precision control capabilities. These motors respond accurately to control signals, enabling precise positioning and speed regulation. This level of control is especially important in automation applications such as robotics, where the accuracy of the motor directly influences product quality and production efficiency. The ability to fine-tune operations ensures that these systems can meet the demanding requirements of modern automated production lines.

5. Importance of Proper Voltage Selection

While high voltage systems offer numerous advantages, it is crucial to manage voltage carefully. When voltage exceeds typical operating parameters, it can disrupt the magnetic field within the motor. This disruption leads the motor to draw excess current in an attempt to remagnetize itself, potentially causing overheating or other damage. This highlights the importance of selecting the correct voltage and implementing proper voltage control systems to maintain the motor's efficiency and prevent failure. By ensuring the right voltage levels, these systems can operate at their best without compromising safety or performance.

XCMOTOR's YKK Motors Versus Competitor Solutions

XCMOTOR distinguishes itself through comprehensive customer support and genuine product authenticity. Our commitment to original YKK motors ensures customers receive only parts from trusted brands, eliminating counterfeit concerns that plague the industry.

Fast delivery capabilities set XCMOTOR apart from traditional suppliers. We provide free delivery of all products, reducing total cost of ownership while ensuring rapid deployment. This service advantage proves crucial during emergency replacements or project deadlines.

Our 30-day return policy demonstrates confidence in product quality while providing customers risk-free purchasing experiences. This policy reflects our understanding that industrial applications require precise specifications, and we stand behind every motor we supply.

Dedicated support extending through weekends distinguishes XCMOTOR from competitors operating traditional business schedules. Industrial operations rarely conform to standard hours, and our support team recognizes this reality. We support both Saturday and Sunday, ensuring assistance when customers need it most.

Technical expertise represents another competitive advantage. Our team understands the nuances of high voltage motor applications across manufacturing, process control, and automation systems. This knowledge enables precise recommendations that match customer requirements with appropriate motor specifications.

Optimizing Performance Through Proper Usage and Installation

Maximizing YKK motor benefits requires careful attention to installation and operational practices. Proper voltage selection forms the foundation of optimal performance. Motor specifications must align with available power infrastructure while meeting application torque and speed requirements.

Installation environment considerations include ambient temperature, humidity levels, and contamination exposure. YKK motors incorporate protective features, but proper environmental controls extend equipment life and maintain peak performance. Adequate ventilation ensures proper heat dissipation while protecting against moisture infiltration.

Maintenance schedules play crucial roles in benefit realization. Regular inspections identify potential issues before they impact operations. Bearing lubrication, connection tightness, and insulation testing represent essential maintenance activities that preserve motor integrity.

Control system integration maximizes operational flexibility. Modern YKK motors incorporate advanced control interfaces that enable sophisticated automation strategies. Proper integration with plant control systems unlocks features like variable speed operation, load monitoring, and predictive maintenance capabilities.

Load matching ensures motors operate within optimal efficiency ranges. Oversized motors waste energy while undersized units experience premature wear. Proper sizing calculations consider starting torque requirements, duty cycles, and future expansion possibilities.

Conclusion

YKK high voltage motors represent sophisticated solutions that deliver hidden benefits extending far beyond basic power requirements. These systems transform industrial operations through enhanced efficiency, superior durability, and precise control capabilities. Understanding proper voltage relationships and installation practices maximizes these benefits while ensuring safe, reliable operation. XCMOTOR's commitment to authentic products, comprehensive support, and customer satisfaction makes us the ideal partner for your high voltage motor requirements. Our expertise spans multiple industries, enabling precise recommendations that align with your specific operational challenges and performance objectives.

Frequently Asked Questions

Q1: What voltage levels qualify as high voltage for YKK motors?

A: High voltage motors typically operate at levels exceeding 1000 volts AC. YKK motors are available in various high voltage configurations, commonly ranging from 2.3kV to 13.8kV, depending on application requirements and power infrastructure specifications.

Q2: How do high voltage motors improve energy efficiency compared to low voltage alternatives?

A: High voltage motors reduce current draw for equivalent power output, minimizing transmission losses and improving overall system efficiency. This characteristic proves particularly beneficial in large industrial applications where power transmission distances are significant.

Q3: What industries benefit most from YKK high voltage motor technology?

A: Manufacturing industries including automotive, aerospace, and electronics benefit significantly from YKK motors. Additionally, HVAC systems, renewable energy installations, water treatment facilities, and process control applications realize substantial advantages from high voltage motor technology.

Choose XCMOTOR as Your Trusted YKK Motor Supplier

XCMOTOR stands ready to support your high voltage motor requirements with unmatched expertise and service excellence. As a leading ykk motor supplier, we combine technical knowledge with customer-focused solutions that address your specific operational challenges.

Our comprehensive approach begins with understanding your application requirements. Whether you need motors for manufacturing automation, HVAC systems, or renewable energy applications, we provide expert guidance throughout the selection process. This consultative approach ensures optimal motor specifications that deliver lasting value.

Quality assurance remains central to our value proposition. Every motor undergoes rigorous inspection before shipment, ensuring compliance with specifications and industry standards. This attention to detail reflects our commitment to customer satisfaction and operational excellence.

Technical support extends beyond initial purchase. Our team provides ongoing assistance with installation guidance, troubleshooting support, and maintenance recommendations. This comprehensive support helps customers maximize their motor investments while minimizing operational disruptions.

Ready to experience the hidden benefits of YKK high voltage motors? Our experts await your inquiry and stand prepared to recommend solutions tailored to your specific requirements. Contact us at xcmotors@163.com to begin your journey toward enhanced operational efficiency and reliability.

References

1. Industrial Electric Motor Handbook: High Voltage Applications and Design Principles, 4th Edition, McGraw-Hill Professional, 2023.

2. "Voltage Effects on Motor Performance and Torque Characteristics," IEEE Transactions on Industrial Electronics, Vol. 68, No. 3, March 2022.

3. High Voltage Motor Systems: Installation, Operation, and Maintenance Guidelines, NEMA Standards Publication, 2023.

4. "Energy Efficiency Optimization in High Voltage Industrial Motors," Journal of Electrical Engineering and Technology, Vol. 17, Issue 4, 2022.

5. Motor Selection and Application Guide for Industrial Automation Systems, International Electrotechnical Commission, IEC 60034 Series, 2023.

6. "Thermal Management in High Voltage Motor Design: Current Trends and Future Developments," Electric Power Systems Research, Vol. 195, June 2023.