Selecting the Right IEC Low Voltage Motor for Your Facility

How to Pick the Right IEC Low Voltage Motors includes figuring out how much power is needed, how the motor will be used, and what the application needs. Built to IEC Low Voltage Motors standards, these motors work reliably in HVAC, process control, and industry. The right choice of motor increases working efficiency, lowers energy use, and improves long-term dependability, all of which are important for industrial sites in a wide range of industries.

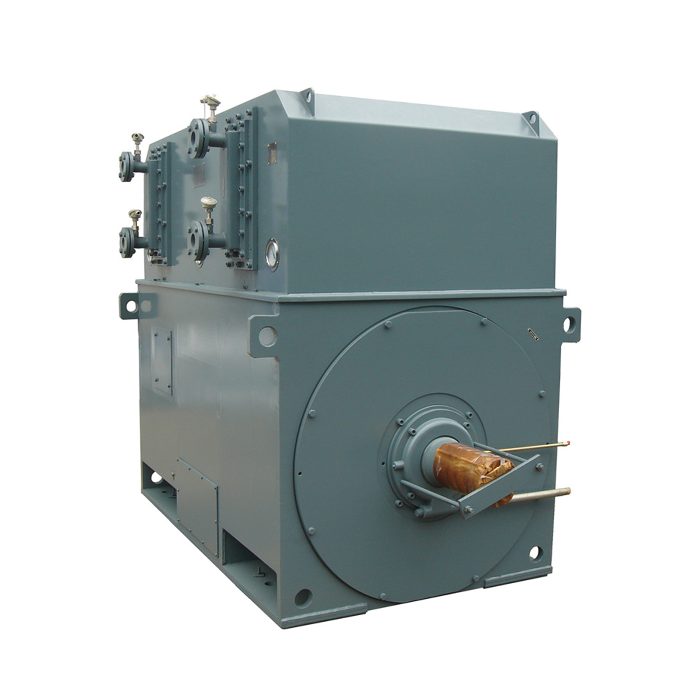

Series:YVFE4

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding IEC Standards and Low Voltage Motor Classifications

In order to make sure that motors work with each other and meet performance standards around the world, the International Electrotechnical Commission sets out detailed rules. These guidelines set the parameters for power ranges, efficiency levels, and safety requirements that modern factories need.

Low voltage motors usually work between 220V and 690V, so they can be used in most commercial settings without the need for special electrical equipment. The IEC guidelines make sure that these motors work the same way no matter who makes them or where they are located, so building managers can be sure that the tools they choose will work well.

AC motors that are made to IEC standards use advanced winding methods and heat safety systems that make them last longer and require less upkeep. The electromagnetic systems in these three-phase motor designs are very well thought out and work very well to turn electrical energy into mechanical output with very little loss.

Under IEC Low Voltage Motors guidelines, the types of motor shielding have direct effects on the highest and lowest temperatures that the motor can work at and the levels of weather tolerance. In standard workplace settings, Class F insulation systems work fine, but Class H systems offer better safety for tough jobs that need to be done in situations with high temperatures or other problems.

Key Performance Factors for Motor Selection

Efficiency Ratings and Energy Saving

Efficiency ratings are critical for operational costs and environmental impact. While maintaining full torque across fluctuating loads, IE4 efficiency class motors assist minimize energy consumption, which ensures optimum performance in applications that are focused on reducing energy consumption.

Motor Frame Size and Durability

It is important to consider mounting compatibility and heat dissipation while determining the frame size. Cast iron frames are great for heavy-duty applications owing to their endurance, whilst aluminum frames give a weight advantage for specialized installations, combining performance with practicality. Cast iron frames are ideal for applications that need exceptional durability.

Power Rating Alignment

The selection of the appropriate motor power rating in accordance with the actual load requirements is of all-important importance. The best efficiency and lifetime of motors are ensured when they are operating close to their rated capacity. This also helps to prevent problems caused by oversizing or undersizing.

Variable Frequency Drive Compatibility

The compatibility of VFDs is an essential component of automation. To better manage the electrical properties of frequency-controlled power supply, motors that are built for variable frequency drives (VFDs) use improved bearing systems and unique winding arrangements.

Core Applications and Implementation Strategies

Pumping Systems and Fluid Handling Equipment

In industrial pumping uses, IEC Low Voltage Motors are needed to keep the power constant and the process smooth even when the pressure changes. Facilities that fix water need motors that can handle a lot of wetness, and places that work with chemicals need motors that can handle rust and have exact speed control to keep flow rates steady and make sure the process is safe.

Material Handling and Conveyor Systems

For conveyor uses, motors must be able to handle many starts, stops, and changes in direction while still keeping the speed steady. Motors with strong gears and heat safety for long job cycles work best in heavy-duty systems. For automated sorting systems to work well and efficiently, they need accurate speed control and quick responses.

Machine Tool and Manufacturing Equipment

For accurate measurements, precision manufacturing equipment needs motors that don't shake too much and have stable power. Motors that can quickly increase speed and change speeds need to be used in CNC and automatic systems. For big machines like presses and rolling mills, motors need to be able to handle high starting torques and heavy loads all the time, even when conditions are rough.

HVAC and Climate Control Systems

Fans, blowers, and circulation pumps in commercial HVAC systems all have motors that run all the time to keep the air flowing. Because they are so important to building processes, these applications need to work reliably and need little upkeep.

The motors used in refrigeration compressor systems must have exceptional starting characteristics and the ability to maintain steady operation across a wide range of load situations. As a result of the fact that these applications often work in temperature-controlled situations, specialist motor cooling and protection systems are an absolute need.

It is necessary for large-scale air handling systems to have motors that are able to move significant amounts of air while yet keeping an energy energy efficiency. It is possible for these systems to modify the flow of air dependent on the occupancy level and the circumstances of the surrounding environment thanks to their variable speed capabilities.

Process Control and Automation Equipment

Automated valve actuators need motors that can precisely place themselves and work reliably under a range of load situations. A lot of the time, these apps work with process control systems that need regular movement responses to work right.

Motors in robotic systems are very good at controlling speed and locating objects accurately. For industrial automation uses, motors need to be able to quickly speed up and slow down while still being easy to control.

Process mixing and agitation equipment requires motors with stable operation under varying viscosity conditions. These applications often operate continuously with load variations that demand robust motor designs capable of handling changing operational demands.

Power Generation and Utility Applications

Auxiliary equipment in power generation facilities requires motors capable of reliable operation in demanding environments. Cooling pumps, fuel handling systems, and environmental control equipment depend on robust motor systems for continuous operation.

Wind turbine pitch control and yaw systems utilize specialized motors designed for outdoor operation and precise positioning requirements. These applications demand motors with enhanced environmental protection and reliable operation under extreme weather conditions.

Water distribution systems require motors capable of maintaining consistent pressure and flow rates across varying demand conditions. These critical infrastructure applications demand reliable motor operation to ensure continuous service delivery.

Transportation and Mobile Equipment

Traction systems for trains need IEC Low Voltage Motors that can handle changing loads and long repair gaps. Marine uses need motors that can withstand high levels of shaking and rust so they can work reliably in difficult circumstances. For steady outdoor performance, airport ground support equipment needs motors that can start and stop reliably and need little upkeep.

Environmental Considerations and Protection Requirements

Industrial settings have problems like dust, wetness, high temperatures, and chemical exposure, so safety grades and building materials need to be carefully looked at to make sure motors work properly. IP grades, like IP55, provide basic security. In tougher environments, higher levels may be needed to keep the motor from breaking down.

Extreme temperatures and chemical contact can hurt the function and life of a motor. Standard motors work well between -20°C and +40°C, but for some uses, they may need better cooling systems or materials that have been changed. Coatings and seals that don't rust are also needed because of chemical contact. This makes sure that the motor parts can handle tough conditions and last a long time.

Installation and Maintenance Considerations

Proper motor installation requires precise alignment, stable mounting, and secure electrical connections to prevent issues like vibration that affect reliability. High-quality bearings and correct electrical setups ensure safe and efficient operation.

Routine maintenance schedules, including vibration monitoring and thermal imaging, detect issues early, extending motor lifespan and improving reliability. Regular checks help optimize performance and prevent unforeseen failures, ensuring ongoing operational efficiency.

Integration with Modern Control Systems

Modern industrial facilities depend on sophisticated control systems that require seamless motor integration. Motors must support various communication protocols and soft start features to avoid mechanical stress. Energy monitoring allows tracking of motor performance, supporting predictive maintenance and energy management, optimizing operational efficiency and identifying improvement opportunities.

Cost-Benefit Analysis and Return on Investment

Motor selection impacts long-term costs, balancing energy use, maintenance, and replacement intervals. Efficient motors justify higher initial costs with long-term savings. Proper sizing prevents energy waste, while reliability reduces downtime and maintenance, ensuring superior value from high-quality, reputable motor systems despite higher upfront investment.

Future-Proofing Your Motor Selection

Advancements in motor design improve efficiency and reliability, ensuring compatibility with future upgrades and automation. IEC standardization allows flexibility for replacements and streamlines maintenance. High-efficiency motors reduce energy consumption and environmental impact, exceeding current standards to ensure compliance with evolving environmental regulations and future-proof your facility.

Conclusion

Selecting appropriate IEC Low Voltage Motors requires careful evaluation of operational requirements, environmental conditions, and integration needs. Understanding IEC specifications and performance characteristics enables informed decisions that optimize both initial investment and long-term operational costs. Quality motor systems provide reliable operation, reduced maintenance requirements, and enhanced energy efficiency that supports sustainable facility operations. Working with experienced suppliers ensures access to technical expertise and comprehensive support throughout the motor selection and implementation process.

Frequently Asked Questions

1. What voltage range should I consider for my facility?

Most industrial facilities operate effectively with 380-480V three-phase power systems that provide optimal balance between safety and performance. Higher voltage systems reduce conductor requirements for large motor installations, while lower voltages simplify electrical infrastructure requirements. Your electrical system capacity and local utility standards typically determine the most appropriate voltage selection for your specific application.

2. How do I determine the correct motor frame size?

Motor frame size selection depends on mounting space limitations, heat dissipation requirements, and mechanical load characteristics. Larger frames provide better cooling capacity and typically offer longer service life, while compact frames suit space-limited installations. Review manufacturer specifications for dimension drawings and mounting requirements to ensure proper fit within your equipment design.

3. What efficiency class should I specify?

IE4 efficiency class represents current best practice for new motor installations, providing optimal energy performance while remaining cost-effective for most applications. Higher efficiency motors reduce operational costs through lower energy consumption, typically justifying premium pricing within 2-3 years through energy savings alone.

4. How important is bearing selection?

Bearing quality significantly affects motor reliability and maintenance requirements. Premium bearing systems from established manufacturers provide extended service intervals and reduced maintenance costs. Applications with heavy loads, frequent starts, or challenging environmental conditions particularly benefit from upgraded bearing specifications.

5. What protection rating do I need?

IP55 protection provides adequate moisture and dust resistance for most indoor industrial applications. Outdoor installations or environments with significant moisture exposure require IP56 or higher ratings. Chemical processing and washdown areas may require specialized sealing systems beyond standard IP ratings.

6. Can I use these motors with variable frequency drives?

Modern motors designed for VFD compatibility incorporate enhanced insulation systems and bearing protection to handle variable frequency operation. Standard motors may require additional protection devices when used with frequency drives. Verify VFD compatibility specifications with the manufacturer to ensure proper system integration.

Choose XCMOTOR as Your Trusted IEC Low Voltage Motor Supplier

XCMOTOR delivers premium motor solutions engineered to meet demanding industrial requirements while providing exceptional value and reliability. Our comprehensive range includes motors from 0.75kW to 1000kW with IE4 efficiency ratings and robust construction designed for continuous operation, including IEC Low Voltage Motors. Contact our technical team at xcmotors@163.com to discuss your specific requirements and receive expert guidance on selecting the optimal motor solution for your facility's unique operational demands.

References

1. International Electrotechnical Commission. "IEC 60034-1: Rotating Electrical Machines - Part 1: Rating and Performance." Geneva: IEC Publications, 2017.

2. European Committee for Standardization. "EN 50347: General Purpose Three-Phase Induction Motors Having Standard Dimensions and Outputs." Brussels: CEN-CENELEC, 2018.

3. Institute of Electrical and Electronics Engineers. "IEEE 841: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled Motors." New York: IEEE Press, 2021.

4. National Electrical Manufacturers Association. "NEMA MG 1: Motors and Generators Standards Publication." Rosslyn: NEMA Publications, 2020.

5. Johnson, Robert M. "Industrial Motor Selection and Application Guide." McGraw-Hill Professional Engineering Series, 2019.

6. Anderson, Patricia L. "Energy Efficient Motor Systems: Design, Selection, and Implementation." CRC Press Industrial Engineering Series, 2022.