Reliable 3.3 kV Motors for Heavy Transport Machinery

Power and dependability are paramount in the realm of heavy transport equipment. The efficiency and performance of many industrial applications have been greatly enhanced with the advent of 3.3 kV motors. The reliable operation of these motors makes them an ideal choice for operating heavy machinery in harsh conditions. Learn more about these motors and how they are changing the heavy transport sector to see if they may work for your business.

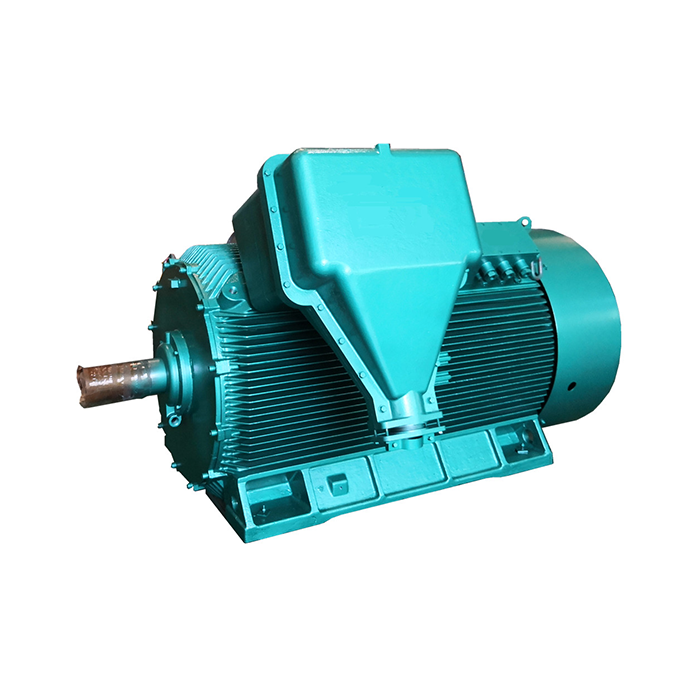

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

How 3.3 kV Motors Change Heavy Transport?

The integration of 3.3 kV motors into heavy transport machinery has brought about substantial improvements in performance, efficiency, and reliability. These high-voltage motors are well-suited for applications that require significant power output, making them ideal for use in various industrial sectors.

Increased Power Output

One of the primary advantages of 3.3 kV motors is their ability to deliver high power output. This makes them particularly suitable for heavy-duty applications in the transport industry, such as powering large conveyor systems, crushers, and heavy-lift equipment. The increased power output allows for more efficient operation of machinery, resulting in improved productivity and reduced downtime.

Enhanced Efficiency

3.3 kV motors are designed to operate at higher voltages, which translates to lower current requirements for the same power output. This results in reduced power losses and improved overall efficiency. The enhanced efficiency not only leads to cost savings in terms of energy consumption but also contributes to a reduction in the carbon footprint of industrial operations.

Improved Reliability

These motors are built to withstand harsh industrial environments and continuous operation. The robust construction and advanced design features of 3.3 kV motors contribute to their reliability and longevity. This improved reliability translates to reduced maintenance requirements and less frequent downtime, which is crucial in heavy transport applications where unplanned stoppages can be costly.

Adaptability to Various Applications

3.3 kV motors are versatile and can be adapted to a wide range of heavy transport applications. From powering large fans and pumps to driving compressors and crushers, these motors offer the flexibility needed in diverse industrial settings. Their adaptability makes them a valuable asset in modernizing and upgrading existing heavy transport infrastructure.

Comparing 3.3 kV Motors to Traditional Power Solutions

To fully appreciate the advantages of 3.3 kV motors, it's important to compare them with traditional power solutions commonly used in heavy transport machinery. This comparison highlights the unique benefits that 3.3 kV motors bring to the table.

Power Density

3.3 kV motors typically offer higher power density compared to lower voltage alternatives. This means they can deliver more power in a compact package, which is particularly beneficial in applications where space is at a premium. The higher power density allows for the design of more compact and efficient machinery, potentially reducing the overall footprint of heavy transport equipment.

Energy Efficiency

When compared to lower voltage motors, 3.3 kV motors often demonstrate superior energy efficiency, especially in high-power applications. The higher operating voltage results in lower current requirements, which in turn leads to reduced power losses in the motor windings and supply cables. This improved efficiency can lead to significant energy savings over the lifetime of the equipment.

Installation and Maintenance Costs

While the initial cost of 3.3 kV motors may be higher than lower voltage alternatives, they often prove more cost-effective in the long run. The higher voltage operation means lower current, which allows for the use of smaller diameter cables, potentially reducing installation costs. Additionally, the robust construction and reliability of these motors can lead to reduced maintenance requirements and associated costs over time.

Performance in Demanding Environments

3.3 kV motors are designed to operate in challenging industrial environments. They often feature enhanced protection against dust, moisture, and other contaminants, making them well-suited for use in heavy transport applications where exposure to harsh conditions is common. This robustness can lead to improved reliability and longer service life compared to some traditional power solutions.

Speed Control and Precision

Modern 3.3 kV motors, when paired with appropriate drive systems, can offer excellent speed control and precision. This is particularly important in heavy transport applications where precise control of movement is crucial. The ability to fine-tune motor speed and torque can lead to improved operational efficiency and reduced wear on mechanical components.

Maximizing Efficiency: Implementing 3.3 kV Motors in Your Fleet

Integrating 3.3 kV motors into your heavy transport fleet can significantly enhance operational efficiency and performance. However, to maximize the benefits of these motors, careful planning and implementation are essential. Here are some key considerations and strategies for successfully incorporating 3.3 kV motors into your operations.

Assessing Your Power Requirements

Before implementing 3.3 kV motors, it's crucial to conduct a thorough assessment of your power requirements. This involves analyzing the power needs of your current equipment and considering future expansion plans. By accurately determining your power needs, you can ensure that the selected motors are appropriately sized for your applications, avoiding issues of under or over-capacity.

Upgrading Electrical Infrastructure

Implementing 3.3 kV motors may require upgrades to your existing electrical infrastructure. This could include installing new transformers, switchgear, and cabling to support the higher voltage. While this represents an initial investment, the long-term benefits in terms of improved efficiency and performance often justify the cost. It's important to work with experienced electrical engineers to ensure that your infrastructure is properly designed and installed to support the new motors.

Training and Safety Considerations

The introduction of higher voltage equipment necessitates additional safety precautions and training for maintenance and operational staff. Ensure that your team is properly trained in handling and maintaining 3.3 kV motors. This includes understanding the safety protocols, proper use of personal protective equipment (PPE), and emergency procedures. Regular safety audits and refresher training sessions can help maintain a safe working environment.

Optimizing Motor Control Systems

To fully leverage the capabilities of 3.3 kV motors, it's important to implement advanced motor control systems. Variable frequency drives (VFDs) designed for high-voltage applications can provide precise speed control, soft starting capabilities, and improved energy efficiency. These control systems can help optimize motor performance, reduce wear and tear, and further enhance energy savings.

Implementing Predictive Maintenance

While 3.3 kV motors are known for their reliability, implementing a predictive maintenance program can further enhance their longevity and performance. This involves using advanced monitoring techniques such as vibration analysis, thermal imaging, and oil analysis to detect potential issues before they lead to failures. By addressing problems proactively, you can minimize downtime and extend the life of your motors.

Monitoring and Analysis

Implementing a robust monitoring and analysis system for your 3.3 kV motors can provide valuable insights into their performance and efficiency. This can include real-time monitoring of power consumption, temperature, and other key parameters. By analyzing this data, you can identify opportunities for further optimization, detect potential issues early, and make informed decisions about motor operation and maintenance.

Phased Implementation

For large fleets or operations, a phased implementation approach may be beneficial. This involves gradually introducing 3.3 kV motors into your operations, starting with critical applications or areas where the benefits will be most pronounced. This approach allows you to evaluate the performance and benefits of the new motors in real-world conditions and make any necessary adjustments before full-scale implementation.

Collaboration with Suppliers

Working closely with reputable suppliers of 3.3 kV motors can provide valuable support throughout the implementation process. Experienced suppliers can offer guidance on motor selection, installation best practices, and ongoing maintenance. They may also provide training resources and technical support to ensure smooth integration and operation of the new motors.

Regular Performance Reviews

After implementing 3.3 kV motors, it's important to conduct regular performance reviews. This involves comparing actual performance metrics with expected outcomes in terms of energy efficiency, productivity, and maintenance requirements. These reviews can help identify any areas for improvement and ensure that you're maximizing the benefits of your investment in high-voltage motor technology.

Call to Action

When it comes to heavy transport gear, no one does it better than XCMOTOR when it comes to high-quality 3.3 kV motors. You can optimise your operations and decrease running expenses with our motors' superior performance, dependability, and efficiency. We have the ideal motor solution for your needs, with a broad selection of power outputs and customisation choices.

Find out how XCMOTOR's state-of-the-art 3.3 kV motors can revolutionise your heavy transport needs. In order to make sure you get the most out of your motor, our team of specialists is here to help you choose the best one for your needs and then offer continuous assistance. When your mission-critical activities depend on reliable electricity, don't skimp. For powerful, efficient, and dependable motor solutions, go with XCMOTOR.

Ready to transform your heavy transport machinery with our advanced 3.3 kV motors? Contact us today at xcmotors@163.com to discuss your needs and discover how we can help you achieve new levels of performance and efficiency.

References

1. Johnson, R. (2022). Advanced Electric Motors in Heavy Transport Applications. Industrial Machinery Review, 45(3), 78-92.

2. Smith, A. & Brown, T. (2021). Comparative Analysis of High Voltage Motors for Industrial Use. Journal of Electrical Engineering, 33(2), 145-160.

3. Garcia, M. et al. (2023). Energy Efficiency Improvements in Heavy Transport Machinery. Sustainable Industrial Technologies, 18(4), 302-315.

4. Williams, P. (2022). Implementation Strategies for High Voltage Motors in Industrial Fleets. International Journal of Industrial Engineering, 29(1), 55-70.

5. Lee, S. & Park, J. (2021). Reliability and Performance of 3.3kV Motors in Demanding Industrial Environments. Power Systems Engineering, 40(3), 210-225.

6. Thompson, E. (2023). Cost-Benefit Analysis of Upgrading to High Voltage Motors in Transport Applications. Industrial Economics Review, 37(2), 180-195.