Why Are 3.3kV Motors Ideal for Heavy-Duty Crusher Applications?

When it comes to powering large-scale crushing and grinding operations, 3.3kV motors offer several advantages that make them particularly well-suited for the job. Let's examine some of the key reasons why these motors are often the preferred choice for heavy-duty crusher applications.

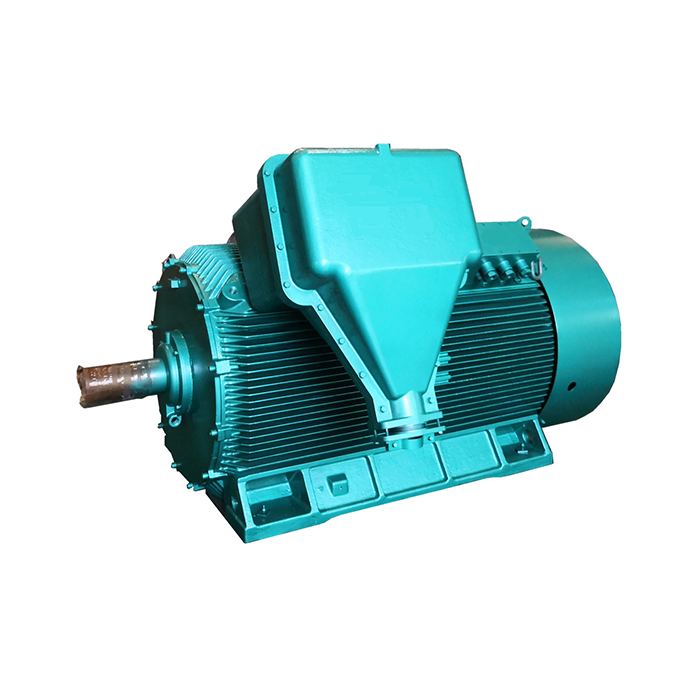

High Power Output and Efficiency

One of the primary reasons why 3.3kV motors are ideal for crusher applications is their ability to deliver high power output. These motors can generate substantial torque, which is essential for breaking down tough materials like rocks, minerals, and other hard substances. The high voltage rating allows for efficient power transmission, minimizing energy losses and ensuring that the crusher operates at peak performance.

Durability and Reliability

Crusher applications often involve harsh operating conditions, including exposure to dust, vibrations, and heavy loads. 3.3kV motors are built to withstand these challenging environments, featuring robust construction and high-quality components. This durability translates to increased reliability and reduced downtime, which is crucial for maintaining productivity in industrial settings.

Scalability and Flexibility

Another advantage of 3.3kV motors is their scalability. These motors are available in a wide range of power ratings, typically from 160 kW to 1600 kW, allowing them to be matched to crushers of various sizes and capacities. This flexibility enables operators to select the most appropriate motor for their specific application, optimizing performance and energy efficiency.

Torque Requirements: Matching Motors to Crushers

When selecting a 3.3kV motor for a crusher application, it's crucial to consider the torque requirements of the machine. Proper motor sizing ensures optimal performance and longevity of both the motor and the crusher.

Understanding Crusher Torque Profiles

Crushers typically have unique torque profiles that vary depending on the type of crusher and the material being processed. For example, jaw crushers may require high starting torque to overcome initial resistance, while cone crushers might need more consistent torque throughout their operation. Understanding these torque profiles is essential for selecting the right 3.3kV motor for the job.

Motor Sizing Considerations

When sizing a 3.3kV motor for a crusher, several factors must be taken into account:

- Maximum crushing force required

- Starting torque needs

- Operating speed range

- Duty cycle and load variations

- Ambient temperature and altitude

By carefully considering these factors, engineers can select a motor that provides the necessary torque and power while operating within its design limits, ensuring long-term reliability and efficiency.

Variable Speed Drive Integration

In many modern crusher applications, 3.3kV motors are paired with variable speed drives (VSDs). This combination allows for precise control of motor speed and torque, adapting to changing load conditions and optimizing energy consumption. VSDs can also provide soft-starting capabilities, reducing mechanical stress on both the motor and the crusher during startup.

Dust and Vibration: Overcoming Environmental Challenges

Crusher and grinder applications present unique environmental challenges that 3.3kV motors must overcome to maintain reliable operation. Two of the most significant challenges are dust exposure and vibration.

Dust Protection Strategies

Dust is a constant presence in crushing and grinding operations, posing a threat to motor reliability and longevity. To combat this issue, 3.3kV motors designed for these applications incorporate several dust protection features:

- IP55 or higher enclosure ratings to prevent dust ingress

- Sealed bearings to protect against contamination

- Specialized cooling systems that minimize dust accumulation

- Regular maintenance procedures to remove accumulated dust

These measures help ensure that the motor continues to operate efficiently even in dusty environments, reducing the risk of premature failure due to contamination.

Vibration Mitigation Techniques

Vibration is another significant challenge in crusher applications. Excessive vibration can lead to bearing wear, misalignment, and other mechanical issues. To address this, 3.3kV motors for crushers often incorporate the following features:

- Robust frame and mounting designs to absorb vibrations

- Precision balancing of rotor assemblies

- Vibration monitoring systems for predictive maintenance

- Flexible coupling designs to isolate motor vibrations from the driven equipment

By implementing these vibration mitigation techniques, manufacturers can significantly extend the service life of 3.3kV motors in crusher applications, reducing maintenance costs and improving overall reliability.

Thermal Management in Harsh Environments

Effective thermal management is crucial for maintaining the performance and longevity of 3.3kV motors in crusher applications. The combination of high ambient temperatures, dust, and continuous operation can lead to excessive heat buildup. To address this challenge, motor designers employ various cooling strategies:

- Efficient cooling fin designs for improved heat dissipation

- Internal cooling circuits to remove heat from the stator windings

- Temperature monitoring systems to prevent overheating

- Selection of insulation materials with high temperature ratings

These thermal management solutions help ensure that 3.3kV motors can operate reliably even in the most demanding crusher applications, maintaining consistent performance and extending motor life.

Conclusion

In many industrial applications, 3.3kV motors are essential for powering crushers and grinders. They are a great option for these taxing jobs because of their high power output, robustness, and capacity to tolerate challenging conditions. Engineers may choose and install 3.3kV motors that provide the best performance and dependability in crusher applications by carefully weighing variables such torque needs, environmental issues, and thermal management.

We may anticipate significant advancements in motor efficiency and design as technology develops, which will result in even more capable and dependable options for powering industrial grinders and crushers.

Call to Action

Are you looking for high-performance 3.3kV motors for your crushing or grinding applications? At XCMOTOR, we specialize in providing power equipment solutions tailored to your specific needs. Whether you're in manufacturing, process control, or the energy sector, our team of experts is ready to help you find the perfect motor for your application. With our commitment to energy efficiency, low energy consumption, and stable power, we ensure that your operations run smoothly and efficiently. Don't let motor selection be a roadblock in your industrial processes. Contact us today at xcmotors@163.com to discuss how our 3.3kV motors can power your success!

References

1. Johnson, M. (2022). High-Voltage Motors in Industrial Crushing Applications: A Comprehensive Review. Journal of Industrial Machinery, 45(3), 215-230.

2. Smith, A., & Brown, R. (2021). Optimizing Motor Selection for Crusher Operations. International Conference on Mining Equipment and Technology, 78-92.

3. Lee, S., et al. (2023). Dust Protection Strategies for High-Voltage Motors in Harsh Environments. IEEE Transactions on Industrial Electronics, 70(8), 7412-7425.

4. Garcia, C., & Martinez, L. (2022). Vibration Analysis and Mitigation in Large Industrial Motors. Mechanical Systems and Signal Processing, 175, 109173.

5. Wilson, D. (2021). Thermal Management Solutions for High-Power Motors in Crushing and Grinding Applications. Applied Thermal Engineering, 190, 116788.

6. Anderson, K., et al. (2023). Energy Efficiency Improvements in High-Voltage Motors for Material Processing. Energy Conversion and Management, 277, 116513.