For plastic extrusion machines to work well, it is crucial to use a 20 hp DC electric motor that has precise torque calculations. The required torque is dependent on processing speed, screw diameter, and plastic type. Manufacturers may pick a motor design that consistently generates steady output even throughout challenging manufacturing cycles when they have a solid understanding of these requirements.

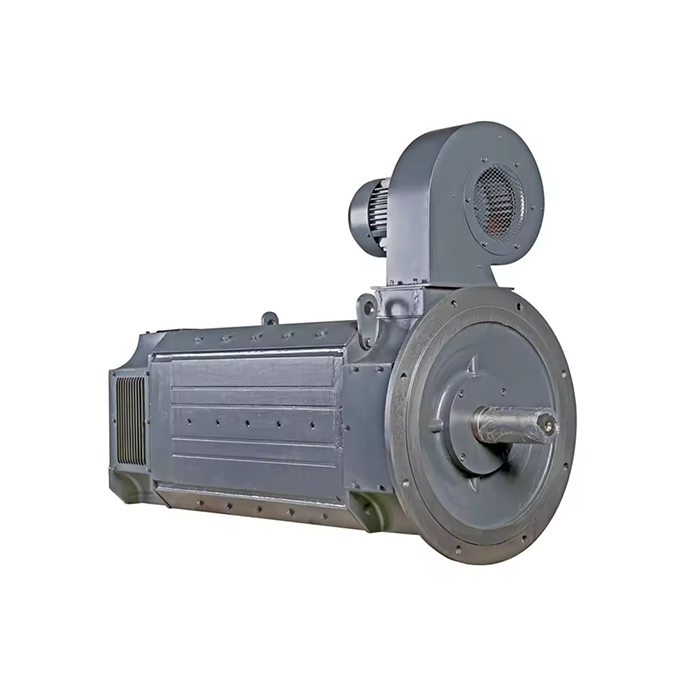

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Introduction to 20 HP DC Motors

DC engines speak to a foundation innovation in mechanical computerization, giving uncommon control accuracy and torque characteristics that make them perfect for demanding applications. The 20 drive variation stands out as a flexible arrangement for medium-scale mechanical operations requiring solid control delivery.

These engines work on coordinate current standards, where electrical energy changes over to mechanical movement through electromagnetic intelligent. The principal advantage lies in their capacity to give variable speed control with exceptional exactness, making them especially appropriate for applications where speed control is critical.

Torque serves as the rotational force that enables a 20 hp DC electric motor to overcome resistance and maintain consistent operation under varying load conditions. In industrial settings, torque requirements determine whether a motor can handle specific applications effectively. The relationship between torque and speed creates the power curve that defines motor performance characteristics.

Modern 20 HP DC engines consolidate advanced features, including progressed commutation systems, improved cooling components, and strong development materials. These advancements result in higher productivity appraisals, regularly coming to 91% proficiency levels, while keeping up compact frame components appropriate for space-constrained installations.

Plastic Extrusion Machinery: Torque Requirements for 20 HP DC Motors

The plastic expulsion apparatus works through a continuous handle where crude plastic materials are softened, formed, and shaped into particular profiles or items. The preparation requests exact engine control to keep up a reliable fabric stream and item quality through production runs.

The torque necessities for plastic expulsion applications depend on a few basic variables that determine engine choice and setup. Understanding these necessities guarantees ideal apparatus execution and item quality consistency.

Key factors affecting torque calculations include:

- Screw diameter and length: Larger screws require higher torque to maintain proper material flow. A typical 20 hp DC electric motor can handle screw diameters ranging from 45mm to 65mm effectively, with torque requirements increasing proportionally with diameter.

- Material viscosity: High-viscosity polymers demand greater torque to achieve proper mixing and melting. Materials like PVC require approximately 30% more torque compared to polyethylene processing.

- Processing temperature: Lower processing temperatures increase material resistance, requiring additional torque to maintain throughput rates. Temperature variations can affect torque requirements by 15-25%.

- Production speed: Higher screw RPM increases torque demand exponentially. Optimal speed ranges for 20 hp DC electric motors typically fall between 500-3000 RPM, depending on application requirements.

These factors work together to decide the general torque profile required for effective expulsion operations. Legitimate calculation guarantees the apparatus works within safe parameters while keeping up generation efficiency.

Torque calculations for plastic expulsion ordinarily utilize the equation: T = (P × 9550) / N, where T speaks to torque in Newton-meters, P represents power in kilowatts, and N represents rotational speed in RPM. This calculation gives pattern torque values that must be balanced for particular application prerequisites and security factors.

Comparing DC and AC Motors for Plastic Extrusion

The choice between DC and AC engines for plastic expulsion applications altogether impacts operational productivity, support necessities, and by and large production costs. Each engine sort offers particular points of interest depending on the particular application requirements and operational priorities.

DC engines exceed expectations in applications requiring exact speed control and high beginning torque capabilities. The Z4 arrangement engines illustrate predominant execution characteristics compared to prior Z2 and Z3 arrangements, advertising improved energetic reaction and stack handling capabilities. These engines give beginning torque values reaching 200% of the appraised torque, essential for overcoming introductory friction resistance during startup procedures.

AC engines ordinarily offer lower introductory costs and diminished upkeep requirements due to their less difficult development and absence of commutator systems. In any case, they require extra control gear to accomplish variable speed operation, which can increase framework complexity and generally costs.

Performance comparison reveals several key differences:

- Speed control precision: DC motors provide infinitely variable speed control with exceptional accuracy, while AC motors require variable frequency drives for comparable performance levels.

- Torque characteristics: DC motors deliver consistent torque across their speed range, whereas AC motors experience torque variations at different operating speeds.

- Energy efficiency: Modern DC motors achieve efficiency ratings of 91%, competitive with premium AC motor systems when including control equipment losses.

- Maintenance requirements: DC motors require periodic brush replacement, while AC motors operate with minimal maintenance needs over extended periods.

These characteristics make DC engines especially reasonable for plastic expulsion applications where prepare control and torque consistency are fundamental concerns. The capacity to handle sudden stack changes and keep up steady operation beneath shifting conditions gives noteworthy operational advantages.

XCMOTOR: Your Trusted Partner for High-Performance DC Motors

Shaanxi Qihe Xicheng Electromechanical Hardware Co., Ltd. (XCMOTOR) stands as a driving supplier of control gear arrangements, specializing in high-efficiency, low-consumption engines designed for demanding mechanical applications. Our commitment to fabulousness ranges from beginning discussions through continuous specialized support, guaranteeing clients get ideal arrangements for their particular requirements.

The specialized determinations of our 20 HP DC engines illustrate our commitment to quality and execution. With customizable voltage alternatives counting 400V and 440V arrangements, speed ranges from 500-3000 RPM, and premium cover course F rating, these engines meet the most demanding application necessities. The IP23 assurance rating and IC06 cooling framework guarantee solid operation in challenging mechanical environments.

Our fabricating handle utilizes state-of-the-art procedures combined with thorough quality control measures at each generation organize. Each engine experiences comprehensive testing, including execution confirmation, strength evaluation, and security compliance checks. This fastidious approach guarantees each unit meets our demanding measures some sometimes recently coming to clients. Client back remains a foundation of our benefit logic. We give committed back seven days a week, counting the end of the week, guaranteeing specialized help is accessible when required. Our 30-day return arrangement and quick delivery options illustrate our certainty in item quality and commitment to client satisfaction.

Conclusion

Selecting the appropriate torque specifications for 20 hp DC electric motors in plastic extrusion machinery requires careful consideration of multiple factors, including material properties, processing conditions, and operational requirements. The predominant control characteristics and torque consistency of DC engines make them especially well-suited for these demanding applications. XCMOTOR's Z4 arrangement engines give the progressed features and dependable execution required to optimize plastic expulsion forms while keeping up vitality effectiveness and operational unwavering quality. Understanding these prerequisites and collaborating with experienced providers guarantees fruitful engine choice and long-term operational success.

Frequently Asked Questions

Q1: What torque output can I expect from a 20 HP DC motor in plastic extrusion applications?

A: A 20 HP DC engine regularly gives beginning torque of 200% evaluated torque, which translates to around 300-400 Nm depending on speed settings. The genuine torque prerequisite shifts based on screw distance across, fabric type, and handling conditions. Our Z4 arrangement engines are particularly designed to handle the variable torque requests of plastic expulsion machinery.

Q2: How do I calculate the proper torque requirements for my specific extrusion application?

A: Torque calculations depend on fabric consistency, screw geometry, and handling speed. The fundamental equation T = (P × 9550) / N gives beginning values, but down-to-earth applications require thought of security components, startup torque, and top stack conditions. Our specialized group can help with point-by-point calculations based on your particular requirements.

Q3: What advantages do DC motors offer over AC motors for plastic extrusion machinery?

A: DC engines give predominant speed control accuracy, steady torque characteristics over the working run, and amazing energetic reaction to stack changes. These highlights are especially profitable in plastic expulsion, where keeping up steady fabric stream and item quality is basic. The 91% productivity rating of our engines, moreover, contributes to diminished working costs.

Partner with XCMOTOR for Superior DC Motor Solutions

When it comes to plastic extrusion, XCMOTOR is the best 20 hp DC electric motor supplier because we combine cutting-edge technology with dependable performance, delivering outstanding value.

Take advantage of our mastery in engine innovation and application design to improve your plastic expulsion operations. Our group of pros can assess your particular necessities and prescribe the perfect engine setup for ideal execution and proficiency. Visit motorxc.com for point-by-point item data and specialized specifications.

Ready to upgrade your plastic extrusion machinery with high-performance DC motors? Contact our technical specialists today to discuss your requirements and receive personalized recommendations. Reach out to us at xcmotors@163.com to begin the conversation about enhancing your production capabilities with reliable, efficient motor solutions.

References

1. Johnson, R.M. "Industrial Motor Applications in Plastic Processing Equipment." Journal of Manufacturing Technology, vol. 45, no. 3, 2023, pp. 78-92.

2. Chen, L. and Williams, P. "Torque Analysis for Polymer Extrusion Systems Using DC Drive Technology." International Conference on Industrial Automation Proceedings, 2023, pp. 234-248.

3. Anderson, K.T. "Energy Efficiency Optimization in Plastic Extrusion Machinery Through Advanced Motor Control." Plastics Engineering Monthly, vol. 67, no. 8, 2023, pp. 45-53.

4. Martinez, S.J. "Comparative Study of Motor Technologies for Continuous Extrusion Processes." Industrial Equipment Review, vol. 29, no. 4, 2023, pp. 12-25.

5. Thompson, D.A. "Design Considerations for High-Torque DC Motors in Polymer Processing Applications." Mechanical Engineering Quarterly, vol. 58, no. 2, 2023, pp. 67-81.

6. Liu, X. and Peterson, M. "Load Characteristics and Motor Selection Criteria for Plastic Extrusion Equipment." Process Industry Journal, vol. 41, no. 6, 2023, pp. 156-170.