Professional ODM medium voltage induction motor solutions bridge the gap between standard offerings and specialized industrial requirements. When power demands exceed low-voltage capabilities but remain below high-voltage thresholds, medium voltage induction motors become the backbone of critical operations. These motors typically operate between 1100V and 7000V, though industrial applications commonly specify 3000V or higher ratings. Understanding voltage classifications helps engineers select optimal power solutions for their specific applications.

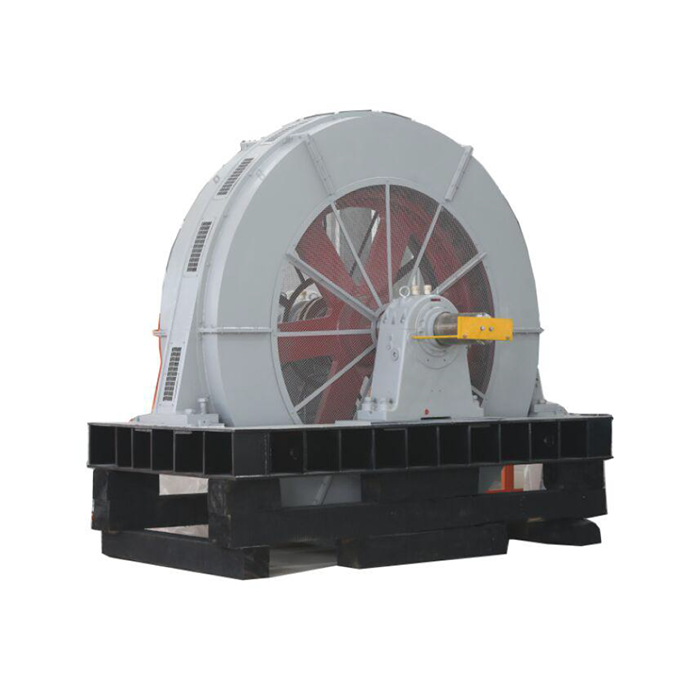

Series:YBBP-HV

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:185-1800 kW

Application:compressors, water pumps, crushers, cutting machine tools, transportation machinery.

Advantage: wide modulation range, high efficiency and energy saving, low noise, long life, high reliability.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding OEM/ODM Excellence in Medium Voltage Motor Manufacturing

The distinction between Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) plays a significant role in shaping the evolution of industrial power solutions. OEM partnerships focus on manufacturing motors based on client specifications. In this arrangement, the client provides detailed design guidelines, and the manufacturer produces the motors to meet these exact requirements. On the other hand, ODM relationships go a step further, involving complete collaboration between the manufacturer and the client in designing and developing the product. ODM allows for more flexibility and innovation, as the manufacturer takes a leading role in designing motors that align with the client's needs and industry-specific challenges.

The Importance of Customization in Medium Voltage Applications

Customization is crucial, especially in medium voltage applications, where every industrial environment presents unique challenges. For instance, manufacturing facilities often require motors that provide specific torque characteristics to handle heavy loads, while process control systems demand motors with precise speed regulation to maintain smooth operations. Standardized motors often fall short in meeting these highly specific requirements, which is why tailored solutions become increasingly important.

With rising energy costs and a growing emphasis on sustainability, market demands are increasingly focused on energy-efficient solutions. Modern industrial applications require motors that not only provide high performance but also consume less energy, reducing overall operational costs. The push for efficiency drives collaboration between manufacturers and clients to develop innovative motor solutions that balance power, performance, and energy conservation.

As industrial applications become more complex, there is a growing need for specialized engineering partnerships rather than relying on generic, off-the-shelf products. This shift reflects the growing importance of tailored solutions that address specific performance needs, energy efficiency goals, and environmental conditions.

Our Comprehensive OEM/ODM Manufacturing Strengths

XCMOTOR brings decades of experience in electric motor manufacturing, particularly in medium voltage induction motors. Our engineering teams understand the complexities of electromagnetic field design and mechanical performance optimization.

Manufacturing capabilities span the complete voltage spectrum from 220V to 13.8kV. This range covers low voltage motors, medium voltage units, and high-voltage applications. Our production facilities maintain strict quality control standards throughout the manufacturing process.

Research and development investments focus on improving efficiency ratings while enhancing reliability. Our laboratories test stator and rotor configurations under various load conditions. Advanced cooling systems undergo rigorous validation to ensure optimal thermal management.

Supply chain partnerships with trusted component suppliers guarantee consistent quality. We source premium insulation materials and precision-machined components. Quality assurance protocols verify every aspect of motor construction before delivery.

Scalability remains a cornerstone of our manufacturing approach. Whether clients need prototype quantities or large production runs, our facilities adapt to meet demand. This flexibility supports both startup ventures and established industrial operations.

Extensive Customization Options for Every Application

Physical Design Customization for Unique Industrial Settings

Physical design customization is a key element in adapting motors to meet the specific demands of diverse industrial environments. Space constraints and mounting requirements often vary significantly from one application to another, which makes it essential to modify frame sizes accordingly. This ensures that motors can be easily integrated into different installation environments, whether in compact machinery or large industrial setups.

Tailored Functional Features for Operational Efficiency

The functional features of medium voltage induction motors can also undergo tailored engineering to align with the specific operational requirements of an industrial process. For example, starting current characteristics can be adjusted to accommodate the limitations of the power supply, preventing potential electrical issues during motor startup. Speed regulation capabilities can be integrated with existing motor control systems to offer precise speed control, which is critical in processes where consistency and accuracy are essential.

Technology Integration for Enhanced Monitoring and Connectivity

Modern motors benefit from technology integration that supports advanced monitoring and smart connectivity features. Sensor packages can be incorporated into the motor to provide real-time operational data, which is crucial for predictive maintenance programs. These sensors help detect early signs of wear, overheating, or other issues, enabling maintenance teams to address potential failures before they occur.

Branding and Documentation Customization

Branding customization goes beyond simple nameplate modifications to align the motor with corporate identity standards. This includes adjusting color schemes to match the company’s branding while ensuring the motor retains proper industrial identification for easy recognition. Additionally, documentation packages are tailored to meet the specific needs of the customer, providing customized technical specifications and maintenance guidelines.

Compliance with Regional and Industry Standards

Compliance certifications are critical in ensuring that motors meet both regional and industry-specific requirements. Our engineering teams work diligently to navigate complex regulatory landscapes, securing the necessary approvals for each motor design. This includes ensuring compliance with safety standards that cover electrical, mechanical, and environmental considerations, which are essential to avoid safety hazards and ensure proper operation in varying conditions.

Our Streamlined Customization Process

Initial consultations focus on understanding specific application requirements and operational constraints. Our technical team evaluates power supply characteristics, load profiles, and environmental conditions. This assessment guides preliminary design recommendations.

Design development phases incorporate client feedback through iterative reviews. Engineering calculations verify performance predictions against application requirements. Thermal analysis ensures adequate cooling under expected operating conditions.

Prototype validation occurs in our testing facilities using standardized procedures. Performance measurements confirm design targets across various operating points. Load capacity testing verifies mechanical strength under extreme conditions.

Production planning addresses manufacturing timelines and quality checkpoints. Regular progress updates maintain transparency throughout the manufacturing cycle. Quality documentation accompanies each delivery for traceability purposes.

Post-delivery support includes installation guidance and commissioning assistance. Technical documentation provides comprehensive maintenance procedures. Ongoing support ensures optimal performance throughout the motor lifecycle.

Measurable Benefits for Your Operations

Cost optimization emerges from precisely matched motor specifications rather than oversized standard units. Energy efficiency improvements directly impact operational expenses through reduced power consumption. Maintenance scheduling becomes more predictable with properly designed cooling systems and bearing selections.

Operational reliability increases significantly when motors match application requirements exactly. Reduced downtime translates to improved productivity and lower maintenance costs. Predictable performance characteristics enable better production planning.

Competitive advantages develop from unique motor specifications that competitors cannot easily replicate. Custom features become differentiating factors in end-product markets. Technical superiority often justifies premium pricing strategies.

Long-term partnerships provide ongoing technical support and continuous improvement opportunities. Design evolution keeps pace with changing application requirements. Volume commitments enable favorable pricing structures.

Conclusion

Professional ODM medium voltage induction motor solutions represent the convergence of engineering expertise and manufacturing excellence. XCMOTOR's comprehensive capabilities transform complex requirements into reliable, efficient power solutions that drive industrial success. From initial consultation through long-term support, our commitment to quality and innovation ensures optimal performance across diverse applications. The future of industrial automation depends on precisely engineered power solutions that deliver measurable advantages in efficiency, reliability, and operational cost reduction.

Frequently Asked Questions

Q1: What voltage ranges qualify as medium voltage for industrial motors?

A: Medium voltage motors typically operate between 1100V and 7000V, though industrial applications commonly specify 3000V or higher. Motors below 690V are classified as low voltage, while units above 10000V enter high voltage categories.

Q2: How long does custom motor development typically require?

A: Development timelines vary based on complexity, but most custom medium voltage projects complete within 8-16 weeks from specification approval. Complex ODM projects may require additional time for prototype validation and testing.

Q3: What minimum order quantities apply to custom motor projects?

A: Minimum quantities depend on customization complexity and motor specifications. We accommodate prototype orders for development purposes and scale production according to client requirements and business relationships.

Partner with XCMOTOR for Superior Medium Voltage Solutions

XCMOTOR stands ready to transform your medium voltage induction motor requirements into competitive advantages. Our comprehensive ODM capabilities deliver precisely engineered solutions that exceed performance expectations while reducing operational costs.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides complete power equipment solutions backed by proven expertise and reliable support. We commit to delivering high energy efficiency, low energy consumption, and stable power across all applications.

Original parts from trusted brands ensure lasting reliability, while fast delivery keeps projects on schedule. Our 30-day return policy and dedicated weekend support demonstrate commitment to client success. Technical expertise spans pre-sales consultation through long-term maintenance support.

Leading medium voltage induction motor manufacturers understand that custom solutions drive competitive advantages. Ready to explore how professional ODM partnerships can elevate your operations? Contact us at xcmotors@163.com to discuss your specific requirements and discover why industry leaders choose XCMOTOR for their critical power applications.

References

- IEEE Standard 112-2017: Standard Test Procedure for Polyphase Induction Motors and Generators, Institute of Electrical and Electronics Engineers

- IEC 60034-1:2017: Rotating Electrical Machines - Part 1: Rating and Performance, International Electrotechnical Commission

- NEMA MG 1-2016: Motors and Generators Standard, National Electrical Manufacturers Association

- Chapman, Stephen J. "Electric Machinery Fundamentals, Fifth Edition," McGraw-Hill Education, 2012

- Boldea, Ion and Syed Nasar. "The Induction Machines Design Handbook, Second Edition," CRC Press, 2010

- Pyrhönen, Juha, et al. "Design of Rotating Electrical Machines, Second Edition," John Wiley & Sons, 2014