Maintaining YKK motor systems requires comprehensive understanding of voltage parameters, thermal management, and preventive care protocols. High voltage motor operations demand meticulous attention to electrical specifications, as voltage fluctuations beyond optimal ranges can compromise performance dramatically. Proper maintenance ensures extended lifespan, enhanced energy efficiency, and reliable operation across industrial applications. Understanding voltage-related challenges helps technicians prevent costly downtime while maximizing equipment durability and operational excellence in demanding environments.

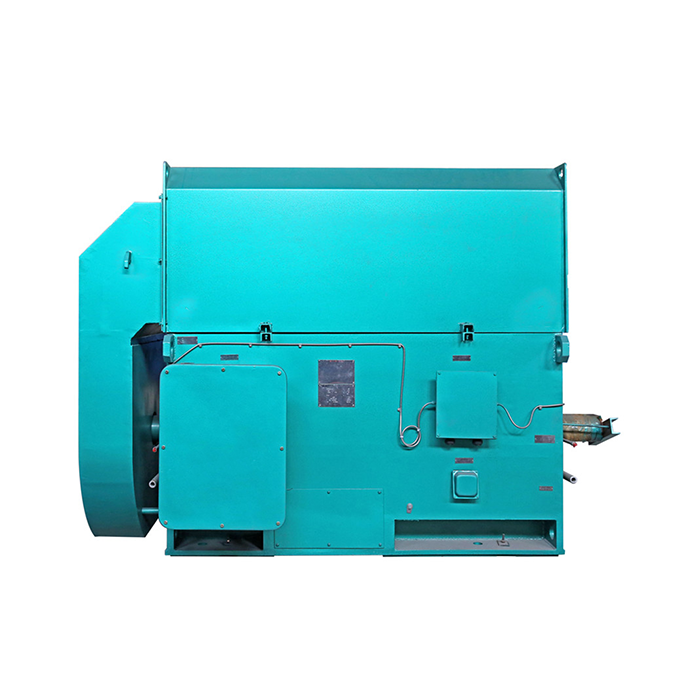

Series:YKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12730 and JB/T 12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding YKK High Voltage Motor Specifications

YKK high voltage motors operate within precise electrical parameters that demand careful monitoring and maintenance. These industrial powerhouses typically function at voltages ranging from 1,000V to 15,000V, making them suitable for heavy-duty applications across manufacturing, process control, and automation systems. The robust design incorporates advanced insulation systems, precision-engineered components, and sophisticated cooling mechanisms.

Voltage stability plays a crucial role in motor performance. When voltage deviates from optimal levels, motor behavior changes significantly. Excessive voltage increases motor torque proportionally to the square of voltage changes. A 110% voltage increase results in 121% torque output, simultaneously elevating starting current and generating excessive heat. This phenomenon creates dangerous mechanical stresses that potentially damage both motor components and connected equipment.

Conversely, insufficient voltage forces motors to draw additional current attempting to maintain rated output. This compensation mechanism generates unwanted heat, reduces efficiency, and accelerates component wear. Understanding these voltage relationships enables maintenance teams to identify potential issues before they escalate into costly failures.

Essential Pre-Maintenance Safety Protocols

1. Comprehensive Safety Measures

Safety is of the utmost importance when servicing high voltage motor systems due to the inherent risks of electrical hazards. Maintenance personnel must be trained to recognize the potential dangers and understand how to mitigate them through established safety protocols. This includes the strict adherence to lockout/tagout procedures, which ensure that the motor's electrical power is completely isolated before any service work begins. These procedures prevent accidental energization and help safeguard workers from electrical shock or burns.

2. Personal Protective Equipment (PPE)

Proper personal protective equipment (PPE) is essential to safeguarding workers from electrical hazards. This includes insulated gloves, which protect against electric shock, safety glasses to shield the eyes from potential arc flashes or debris, and arc-flash protective clothing to mitigate the risks of thermal burns from electrical discharges. Additionally, testing equipment used for voltage checks must be properly rated for the specific voltage levels being worked with. These precautions are critical in minimizing injury and ensuring a safe working environment during high voltage motor maintenance.

3. Voltage Testing and Grounding Procedures

Before beginning any maintenance on YKK motors, voltage testing is essential to confirm complete de-energization of the equipment. Specialized voltage testers should be used to check that no residual power remains in the system. Grounding procedures must also be strictly followed to prevent accidental energization during the maintenance process. Proper grounding helps ensure that any stray electrical currents are safely redirected, significantly reducing the risk of electrical shocks or other hazards to the maintenance team.

4. Work Area Preparation and Emergency Protocols

Preparing the work area is an integral part of ensuring safety during maintenance. Combustible materials should be removed to reduce the risk of fires, especially in the presence of potential arc flashes. The area must also be well-lit to ensure clear visibility of all components, and clear egress paths should be maintained to allow for quick evacuation in case of an emergency. Emergency response plans should be readily available, outlining procedures for administering immediate medical attention in the event of an electrical accident.

5. Regular Calibration and Documentation

Testing equipment must be regularly calibrated to ensure its accuracy. Proper calibration ensures that voltage measurements are precise, helping to confirm that the motor has been safely de-energized before any maintenance work is undertaken. In addition, comprehensive documentation of safety procedures is vital for maintaining consistency across maintenance teams. This documentation also supports compliance with regulatory standards and helps in training new personnel. By keeping accurate records, organizations can track safety measures, improve protocols, and ensure that every maintenance activity is conducted according to the highest safety standards.

Regular Inspection and Monitoring Techniques

Systematic inspection schedules prevent unexpected failures while optimizing motor performance. Visual inspections reveal obvious signs of deterioration, including damaged insulation, corroded terminals, or mechanical misalignment. Thermal imaging identifies hot spots indicating potential electrical or mechanical problems before they cause significant damage.

Vibration analysis detects bearing wear, rotor imbalance, or coupling misalignment issues. Trending vibration data over time reveals gradual deterioration patterns, enabling predictive maintenance strategies. Current signature analysis monitors electrical characteristics, identifying rotor bar defects, stator winding problems, or air gap irregularities.

Insulation resistance testing verifies electrical integrity between windings and ground. Regular megohm readings establish baseline values for comparison during future testing. Oil analysis for oil-filled motors reveals contamination levels, moisture content, and additive depletion requiring attention.

Voltage-Related Maintenance Challenges

Voltage irregularities create significant maintenance challenges requiring specialized attention. Overvoltage conditions disrupt magnetic field stability, forcing YKK motors to draw excessive current while attempting remagnetization. This compensation mechanism generates substantial heat, accelerating insulation aging and potentially causing catastrophic failure.

Motor torque increases dramatically with voltage elevation, creating mechanical stress throughout the drive system. Higher starting currents during overvoltage conditions strain electrical components, including contactors, protective devices, and supply infrastructure. Mechanical components experience increased wear due to elevated torque levels and vibration.

Monitoring systems should track voltage variations continuously, alerting maintenance teams to potentially harmful conditions. Power quality analyzers capture transient events, voltage sags, and harmonic distortion affecting motor operation. Installing voltage regulators or power conditioning equipment helps maintain stable operating conditions.

Documentation of voltage-related incidents supports failure analysis and helps identify recurring patterns. Correlation between voltage events and motor performance degradation guides maintenance scheduling and equipment upgrade decisions.

Preventive Maintenance Scheduling

Structured maintenance schedules optimize motor reliability while minimizing operational disruptions. Daily inspections include visual checks for unusual noise, vibration, or overheating conditions. Weekly procedures involve cleaning air filters, checking lubrication levels, and verifying proper ventilation airflow.

Monthly maintenance includes detailed inspections of electrical connections, terminal tightness, and insulation condition. Quarterly procedures involve comprehensive testing of protection systems, emergency shutdown functions, and cooling system effectiveness. Annual maintenance includes major inspections, bearing replacement, and complete electrical testing.

Condition-based maintenance strategies adjust schedules based on actual equipment condition rather than fixed time intervals. This approach optimizes maintenance resources while preventing unnecessary work on equipment operating satisfactorily. Predictive technologies guide scheduling decisions, extending equipment life while maintaining reliability.

Maintenance records document all activities, test results, and component replacements. Historical data supports warranty claims, regulatory compliance, and future maintenance planning. Trending analysis identifies patterns suggesting design improvements or operational modifications.

Troubleshooting Common High Voltage Motor Issues

Systematic troubleshooting approaches efficiently identify and resolve motor problems. Electrical issues often manifest as abnormal current patterns, unusual noise, or performance degradation. Insulation breakdown typically shows as ground faults, requiring immediate attention to prevent equipment damage or safety hazards.

Mechanical problems include bearing failure, rotor imbalance, or coupling misalignment. These conditions generate characteristic vibration signatures detectable through analysis equipment. Early detection prevents secondary damage to motor components and connected machinery.

Thermal problems result from inadequate cooling, excessive loading, or electrical imbalances. Temperature monitoring identifies overheating conditions requiring immediate investigation. Cooling system blockages, fan failures, or ambient temperature changes contribute to thermal issues.

Environmental factors including moisture infiltration, contamination, or corrosive atmospheres accelerate motor deterioration. Protective measures include improved sealing, filtration systems, or environmental controls maintaining acceptable operating conditions.

Advanced Diagnostic Technologies

Modern diagnostic technologies revolutionize YKK motor maintenance through early fault detection and condition assessment. Motor current signature analysis identifies electrical and mechanical defects by analyzing current waveforms during operation. This non-intrusive technique detects problems without requiring equipment shutdown.

Partial discharge testing reveals insulation deterioration in high voltage motors before complete failure occurs. This technology identifies weak spots in insulation systems, enabling targeted repairs preventing catastrophic breakdowns. Trending partial discharge activity guides replacement timing decisions.

Wireless monitoring systems provide continuous equipment surveillance, transmitting critical parameters to maintenance management systems. Real-time alerts enable rapid response to developing problems, minimizing downtime and repair costs. Data analytics identify patterns supporting predictive maintenance strategies.

Digital twin technology creates virtual models of motor systems, enabling simulation of various operating conditions and maintenance scenarios. These models support optimization efforts and training programs while reducing risks associated with equipment experimentation.

Conclusion

Effective YKK motor maintenance requires comprehensive understanding of voltage relationships, systematic inspection procedures, and advanced diagnostic capabilities. Voltage management remains critical, as both overvoltage and undervoltage conditions create significant operational challenges. Regular maintenance schedules, combined with condition-based monitoring, optimize equipment reliability while minimizing costs. Professional support from experienced suppliers like XCMOTOR ensures access to genuine components, technical expertise, and responsive service. Implementing these maintenance strategies protects valuable motor investments while supporting operational excellence across industrial applications.

Get Professional YKK Motor Support from XCMOTOR

Professional maintenance support ensures optimal YKK motor performance throughout operational lifecycles. XCMOTOR specializes in comprehensive motor solutions, offering expert technical guidance for complex maintenance challenges. Our experienced team understands the unique requirements of high voltage motor systems across diverse industrial applications.

When searching for a reliable ykk motor supplier, consider XCMOTOR's commitment to quality and customer satisfaction. We provide original components from trusted manufacturers, ensuring compatibility and reliability for critical applications. Fast delivery services minimize downtime, while our 30-day return policy demonstrates confidence in product quality.

Technical support extends beyond standard business hours, with dedicated assistance available during weekends when maintenance activities typically occur. Our team addresses pre-sales questions, installation guidance, and ongoing technical challenges. Comprehensive documentation and training resources support successful implementation and operation.

Whether planning preventive maintenance programs or addressing emergency repairs, professional support accelerates resolution while ensuring safety compliance. Contact us at xcmotors@163.com for expert consultation on your YKK motor maintenance requirements.

References

- IEEE Standard 43-2013: IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery. Institute of Electrical and Electronics Engineers, 2013.

- NEMA MG 1-2016: Motors and Generators Standards Publication. National Electrical Manufacturers Association, 2016.

- Bonnett, Austin H. "Root Cause AC Motor Failure Analysis with a Focus on Shaft Failures." IEEE Transactions on Industry Applications, vol. 36, no. 5, 2000.

- Thorsen, Ole Viggo, and Magne Dalva. "A Survey of Faults on Induction Motors in Offshore Oil Industry Applications." IEEE Transactions on Industry Applications, vol. 31, no. 5, 1995.

- Stone, Greg C., et al. "Electrical Insulation for Rotating Machines: Design, Evaluation, Aging, Testing, and Repair." IEEE Press Series on Power Engineering, 2nd Edition, 2014.

- Tavner, Peter J. "Review of Condition Monitoring of Rotating Electrical Machines." IET Electric Power Applications, vol. 2, no. 4, 2008.