When it comes to power plants and mining operations, reliability and efficiency are critical. High voltage motors, such as 6600V units, play a pivotal role in ensuring the smooth operation of heavy-duty machinery and systems. These motors are designed to handle demanding conditions, providing the necessary torque and power to keep essential equipment running. In environments like power generation and mining, where downtime can lead to costly disruptions, the selection of the right motor is crucial. This guide explores some of the best 6600V motors available for these industries, focusing on performance, durability, and energy efficiency to meet the toughest operational needs.

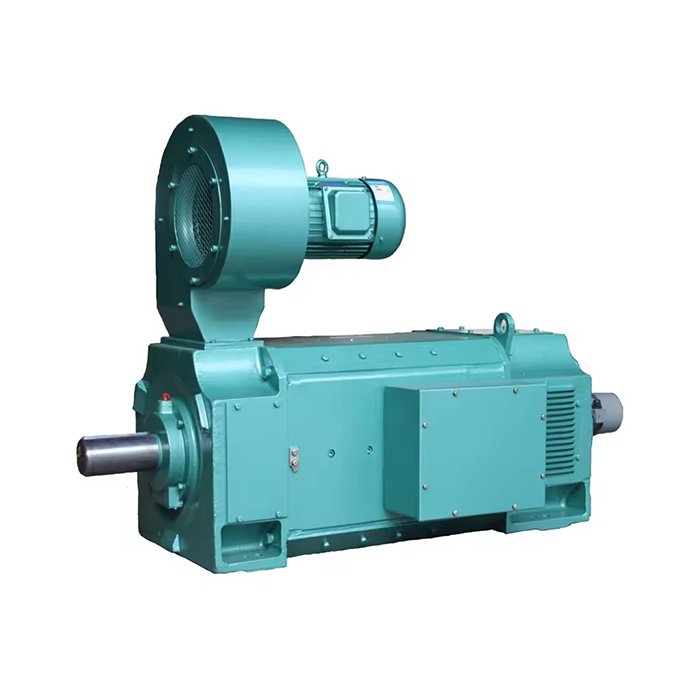

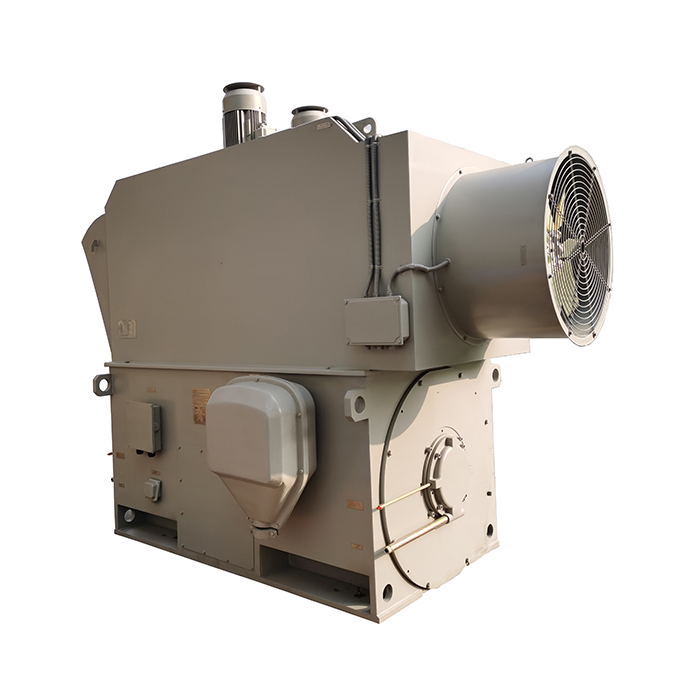

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Introduction

High voltage motors operating at 6600V represent the backbone of industrial power systems worldwide. These robust machines drive everything from massive mining conveyors to power generation turbines, making their selection critical for operational success. The unique demands of power plants and mining operations require motors that withstand extreme conditions while maintaining consistent performance.

Mining environments present particular challenges with dust, moisture, and temperature fluctuations that can compromise standard equipment. Power plants demand unwavering reliability since downtime translates to significant revenue losses. Each 6600V motor must deliver exceptional torque characteristics, superior insulation properties, and compatibility with variable frequency drives for optimal energy consumption control.

Selecting the right high voltage motor involves understanding load capacity requirements, environmental factors, and long-term maintenance considerations. The investment in quality equipment pays dividends through reduced operational costs and enhanced system reliability across industrial applications.

Why Focus on 6600V Motors for Heavy Industry

The 6600V rating strikes an optimal balance between power delivery and safety in industrial applications. This voltage level provides sufficient capacity for large-scale operations while remaining manageable from an electrical engineering perspective. Manufacturing facilities, power generation stations, and mining operations rely on these motors because they efficiently handle substantial loads without requiring extremely complex infrastructure.

Unlike lower voltage alternatives, 6600V systems reduce current requirements for equivalent power output, minimizing conductor costs and heat generation. This efficiency becomes crucial in large installations where cable runs span considerable distances. The reduced phase current also decreases electromagnetic interference, improving overall system stability.

Mining equipment particularly benefits from this voltage level because it supports powerful crushers, mills, and conveyor systems essential for material processing. Power plants utilize these motors for cooling pumps, fuel handling systems, and auxiliary equipment that maintains continuous operation. The synchronous speed capabilities at this voltage enable precise control of critical processes.

Selection Criteria for Optimal Performance

Evaluating 6600V motors requires examining multiple performance factors that directly impact operational success. Efficiency ratings determine long-term energy costs, while power factor characteristics affect overall system performance. Load capacity must match application requirements with appropriate safety margins for peak demand periods.

Environmental resilience stands as another crucial criterion. Motors operating in power plants face temperature extremes and potential exposure to steam or chemical vapors. Mining applications demand protection against abrasive particles and moisture infiltration. The cooling system design significantly impacts reliability in these challenging conditions.

Motor control compatibility ensures seamless integration with existing automation systems. Variable frequency drive compatibility enables precise speed control and energy optimization. Harmonics management becomes essential for maintaining power quality across the facility. Rotor and stator construction quality determines mechanical reliability under continuous operation.

Maintenance accessibility and parts availability influence total cost of ownership. Suppliers offering comprehensive support networks provide significant advantages for critical applications. Local service capabilities reduce downtime during maintenance or emergency repairs.

Top 5 6600V Motors for Industrial Applications

1. ABB M3BP Series High Voltage Motor

The ABB M3BP series is a high-voltage motor designed for demanding industrial applications, featuring advanced squirrel cage construction and optimized rotor geometry for superior torque. The stator windings are made from high-performance insulation materials, ensuring reliable operation at elevated temperatures.

With efficiency ratings exceeding IE3 standards, these motors significantly reduce energy consumption compared to standard units. The forced ventilation cooling system maintains stable temperatures under heavy loads, while precision balancing and robust bearings minimize vibration.

The M3BP series offers installation flexibility, supporting various mounting orientations and connection methods, all while maintaining IP55 protection. It is compatible with variable frequency drives for precise speed control.

Maintenance is simplified due to durable construction and quality materials, including premium lubricants and superior insulation resistant to moisture and chemicals. These motors are ideal for power generation systems, large pumps, and material handling equipment, where performance and reliability are essential.

2. Siemens SIMOTICS HV 1FU8 Motor

Siemens SIMOTICS HV motors, specifically the 1FU8 series, are designed for demanding industrial applications, offering exceptional performance with innovative design and premium materials. The advanced electromagnetic design optimizes power factor and minimizes harmonics.

The cooling system uses patented technology to maintain optimal temperatures, extending motor life and ensuring consistent performance. The insulation system surpasses standard requirements, providing superior protection against voltage surges and contamination. Rotor construction features precision manufacturing, and dynamic balancing reduces vibration, minimizing noise and protecting equipment.

The motors are compatible with Siemens automation systems and third-party control platforms, supporting advanced monitoring and predictive maintenance. They also accommodate various encoder types for precise position feedback.

These motors are ideal for applications like mining crushers, conveyor drives, and power plant cooling systems, where consistent performance is critical.

3. WEG W22 Magnet HV Motor

WEG W22 Magnet HV motors integrate permanent magnet technology with proven design principles to offer reliable high-voltage solutions. The compact design reduces physical size, simplifying installation in space-limited applications. These motors achieve up to 15% energy savings compared to standard motors, with the permanent magnet rotor eliminating slip losses and providing consistent torque across the speed range.

The cooling system ensures optimal magnet temperatures, while temperature monitoring prevents demagnetization. The housing design facilitates easy maintenance access and complies with environmental protection standards.

These motors support regenerative braking, returning energy to the grid during deceleration, which is especially beneficial for applications with frequent start-stop cycles, like mining. Variable speed operation ensures high efficiency across the entire range.

Ideal for applications requiring precise speed control, high efficiency, and compact installations, WEG W22 Magnet HV motors are well-suited for modern industrial facilities.

4. Toshiba Premium Efficiency TM Series

Toshiba TM series motors are designed for premium efficiency, incorporating advanced materials and manufacturing processes. The electromagnetic design optimizes flux distribution and minimizes losses, with copper rotor construction reducing electrical losses compared to aluminum.

The insulation system uses nano-technology materials, enhancing dielectric properties and thermal conductivity for higher power densities and improved reliability. The winding configuration minimizes harmonic generation, improving power quality. The motor's mechanical construction focuses on durability, with precision machining and optimized frame design to prevent potential failure points. Bearing selection and lubrication systems are tailored to specific applications.

Environmental protection is enhanced by specialized coatings that resist corrosion and chemical attack, while the terminal box prevents moisture ingress and ensures easy connections. Gasket materials are resistant to temperature cycling and chemical exposure.

These motors excel in harsh environments, such as chemical processing, water treatment, and power generation, where superior protection and reliability are essential.

5. General Electric 5K Series Motor

General Electric 5K series motors combine decades of engineering advancements in high-voltage technology. The design incorporates proven principles with modern materials, featuring optimized stator core geometry to reduce magnetic losses.

The rotor design includes enhanced cooling channels to maintain optimal temperatures during continuous operation. The squirrel cage construction uses premium conductors that minimize electrical losses and provide superior mechanical strength. Dynamic balancing ensures smooth operation across all speeds. The cooling system offers versatile ventilation options, with forced air cooling for consistent temperatures and self-ventilated designs for simpler applications. Heat exchangers allow operation in contaminated environments.

These motors are compatible with both traditional starter configurations and modern variable frequency drives. Integrated protection systems support predictive maintenance, and communication interfaces enable seamless integration with automation systems.

The 5K series excels in demanding applications like mining conveyors, power plant auxiliaries, and heavy manufacturing, where continuous, reliable operation is crucial.

Global Market Characteristics and Regulations

International markets present diverse regulatory environments affecting 6600V motor selection and operation. European Union directives emphasize energy efficiency through IE3 and IE4 standards that mandate minimum performance levels. These regulations drive technology advancement while reducing operational costs through improved efficiency.

North American markets focus on safety standards through NEMA and IEEE guidelines that specify construction requirements and testing procedures. Canadian Standards Association (CSA) certifications ensure compliance with national electrical codes. These standards influence design parameters and manufacturing processes.

Asian markets demonstrate rapid growth in industrial automation driving demand for advanced motor technologies. Chinese GB standards align with international requirements while addressing local conditions. Indian BIS standards accommodate tropical operating environments common throughout the region.

Environmental regulations increasingly impact motor selection through restrictions on materials and disposal requirements. RoHS compliance eliminates hazardous substances while WEEE directives address end-of-life recycling. These considerations affect initial selection and long-term planning.

Purchasing Recommendations and Considerations

Successful motor procurement requires comprehensive evaluation of technical specifications, supplier capabilities, and total cost of ownership. Initial purchase price represents only a fraction of lifetime costs when energy consumption and maintenance expenses are considered. Efficiency improvements often justify premium pricing through operational savings.

Supplier evaluation should examine manufacturing quality, service network coverage, and technical support capabilities. Local service availability reduces downtime during maintenance or emergency repairs. Training programs ensure proper installation and operation procedures that maximize equipment life.

Application analysis determines appropriate specifications while avoiding over-specification that increases costs unnecessarily. Load characteristics, environmental conditions, and duty cycle requirements influence motor selection. Future expansion possibilities may justify initial over-capacity for simplified upgrades.

Documentation requirements include detailed specifications, test reports, and maintenance recommendations. Warranty terms should reflect application severity and expected service life. Spare parts availability ensures continued operation throughout the motor lifetime.

Industry Trends and Summary

The 6600V motor market continues evolving toward enhanced efficiency and smart monitoring capabilities. Digital integration enables predictive maintenance strategies that reduce unplanned downtime while optimizing performance. Energy regulations drive advancement in efficiency standards while environmental concerns influence material selection and manufacturing processes. These trends benefit end users through improved reliability, reduced operating costs, and enhanced operational visibility across industrial applications.

Conclusion

Selecting optimal 6600V motors for power plants and mining equipment requires careful evaluation of performance characteristics, environmental requirements, and supplier capabilities. The motors discussed represent proven solutions that deliver reliable operation under demanding conditions. Success depends on matching motor specifications to application requirements while considering long-term operational factors. Investment in quality equipment pays dividends through reduced maintenance costs, improved efficiency, and enhanced reliability that supports continuous operations essential for industrial success.

Frequently Asked Questions

Q1: What maintenance intervals are recommended for 6600V motors in mining applications?

A: Mining applications typically require bearing lubrication every 2000-4000 operating hours depending on environmental conditions. Complete inspections should occur annually with comprehensive overhauls every 5-7 years. Harsh environments may necessitate more frequent maintenance schedules.

Q2: Can 6600V motors operate with variable frequency drives for energy savings?

A: Most modern 6600V motors support variable frequency drive operation with appropriate insulation systems. VFD compatibility enables significant energy savings through speed control matching load requirements. Consult manufacturer specifications for specific drive compatibility requirements.

Q3: What environmental protection ratings are essential for power plant applications?

A: Power plant applications typically require IP55 or higher protection ratings to prevent moisture and particle ingress. Steam environments may necessitate IP56 ratings while outdoor installations require appropriate corrosion protection. Climate conditions influence specific protection requirements.

Partner with XCMOTOR for Your 6600V Motor Requirements

XCMOTOR stands ready to support your high voltage motor needs with comprehensive solutions tailored to your specific applications. Our expertise in power equipment solutions encompasses everything from initial specification development through long-term maintenance support. We understand the critical nature of 6600V motor applications in power plants and mining operations.

As a trusted 6600v motor supplier, we maintain relationships with leading manufacturers worldwide, ensuring access to the latest technologies and competitive pricing. Our team evaluates your specific requirements to recommend optimal solutions that balance performance, reliability, and cost considerations. We provide genuine parts from trusted brands with fast delivery capabilities that minimize downtime.

Our commitment extends beyond initial equipment supply through comprehensive after-sales support including technical consultation, maintenance planning, and emergency repair services. We support operations seven days per week because we understand industrial facilities operate continuously. Our 30-day return policy demonstrates confidence in product quality while providing customer protection.

Ready to discuss your 6600V motor requirements? Our technical specialists stand ready to analyze your applications and recommend optimal solutions. Contact us at xcmotors@163.com to begin the conversation about enhancing your facility's performance and reliability.