Proper maintenance of your 20 hp dc electric motor ensures reliable performance across industrial applications while extending operational lifespan significantly. Regular upkeep prevents costly downtime and maintains optimal efficiency in manufacturing, HVAC systems, and energy utilities. This comprehensive guide covers essential maintenance practices that keep your high power electric motor running smoothly through preventive care, troubleshooting techniques, and professional servicing strategies.

Understanding Your DC Motor's Core Components

DC motors contain several critical components that require regular attention.

The Role of the Commutator in Motor Performance

The carbon brushes are responsible for maintaining the appropriate electrical contact, and the commutator is an essential component in this process. Over the course of their use, these brushes will slowly degrade, necessitating their frequent replacement in order to ensure that the motor continues to function at its best.

The Significance of Motor Winding Design

The distribution of heat and the overall electrical efficiency are both impacted by the design of the motor windings. The rotational force is produced by the interaction of the magnetic fields that are generated by the stator windings with the rotor windings. Recognizing how these relationships work assists in the identification of possible problems prior to them becoming serious.

Long-lasting Bearing Assemblies and Shaft Design

The design of the motor shaft allows for the passage of mechanical energy to the equipment that is attached. Shaft rotation is supported by bearing assemblies, which also serve to minimize friction. High-quality bearings, like those produced by well-known manufacturers, are a major factor in the increased lifetime of motors and the decreased amount of maintenance they need.

The Classification of Insulation and the Resistance to Temperature

The resistance of a motor to high temperatures is determined by its insulation class. During high-load operations, windings are protected from thermal damage by Class F insulation, which can normally sustain temperatures up to 155°C. Potential failures may be predicted before they happen if the insulating resistance is being monitored.

Important Procedures for Preventive Maintenance

Routine Inspections to Maintain Your Vehicle

Periodic visual inspections are the first step in the maintenance of a 20 hp dc electric motor. Be on the lookout for any abnormal vibrations, an inordinate amount of noise, or situations in which the temperature is too high. The presence of these symptoms is often an indication that issues are developing and require prompt action.

Replacement and Inspections on a Monthly Basis

Once a month, high-usage applications should be subjected to a thorough check of their brushes. If the brushes are worn, they will not establish a good electrical connection, which will lower the efficiency of the motor and may also cause damage to the surface of the commutator. When they have reached their minimum length criteria, replace the brushes.

Care and Maintenance of Bearing Lubrication

When it comes to bearing lubrication, it is essential to pay close attention to the requirements provided by the manufacturer. When there is not enough lubrication, the rate of bearing wear increases, and when there is too much lubrication, contamination and damage to the seal result. Stick to the approved lubricants and adhere to the set intervals.

Keeping the Cooling System in Good Condition

In order to ensure that the heat dissipation system is functioning properly, the electric motor cooling system must be cleaned on a regular basis. Temperature increases that diminish insulation and shorten the lifetime of motors are caused by blocked ventilation pathways. Make certain that the motor housing is receiving sufficient airflow and that the cooling fins are free of debris.

Experimenting with Systems Designed to Provide Thermal Protection

Periodic testing is necessary to ensure that motor heat protection devices are functioning correctly. When temperatures go over acceptable limits, these devices shut off the motor, which prevents damage from overload circumstances.

Monitoring Performance Indicators

Electric motor efficiency monitoring helps identify gradual performance degradation. Track power consumption patterns and compare them with baseline measurements. Significant increases in power draw often indicate mechanical problems or electrical faults, particularly in a 20 hp dc electric motor.

Monitoring DC Motor Torque Characteristics

As the components get worn out, the torque characteristics of the DC motor change. Keep an eye on the initial torque and the torque while operating under a range of load circumstances. The indication of internal issues that need further examination is provided by a decrease in torque output.

An Analysis of Vibration for Diagnostic Insights

The study of vibrations gives useful diagnostic information about the state of the machinery. When there is an overabundance of vibration, it is a sign that the bearings are worn out, the shaft is misaligned, or the rotor is imbalanced. It is possible to plan maintenance in advance of catastrophic failures by doing regular vibration monitoring, particularly in the case of a 20 hp dc electric motor.

Temperature monitoring is used to detect any issues that may arise

As it turns out, the motor housing exhibits a number of difficulties that are still in their infancy. Although widespread rises in temperature are indicative of difficulties with the cooling system or overload circumstances, hotspots are an indication of electrical failures.

Maintaining Precision in the Regulation of Motor Speed

The precision of motor speed regulation has an impact on the overall performance of the system. In order to ensure that exact speed control is maintained, variable speed drive systems need to be calibrated. Keep an eye on the speed stability while the load circumstances are changing.

Troubleshooting Common Issues

Addressing Motor Startup Current Problems

Motor startup current problems often stem from mechanical binding or electrical faults. Excessive startup current indicates high friction or electrical resistance issues. Check mechanical coupling alignment and electrical connections.

Troubleshooting Brushless DC Motor Issues

Brushless DC motor applications may experience different issues than traditional brush motors. Electronic controllers require specific troubleshooting procedures. Consult technical documentation for proper diagnostic techniques.

Noise Reduction in Electric Motors

Electric motor noise reduction becomes important in noise-sensitive environments. Unusual noise patterns indicate developing problems such as bearing wear, loose components, or electrical arcing. Address noise issues promptly to prevent equipment damage.

Analyzing Torque-Speed Characteristics

Torque-speed characteristics that deviate from normal patterns suggest internal problems. Reduced torque at specific speeds indicates commutator problems or winding faults. Document performance changes to identify trends.

Managing Motor Electromagnetic Compatibility

Motor electromagnetic compatibility issues can affect nearby electronic equipment. Shield sensitive equipment and ensure proper grounding to minimize electromagnetic interference.

Professional Service and Support

To keep industrial electric motors in good shape, you typically need to know a lot about them. Trained technicians know how to put up and optimize DC motor controllers, particularly for systems like a 20 hp dc electric motor. Preventive maintenance routines should match the needs of the business. Motors that are used all the time need more service than motors that are only used seldom. Make maintenance plans depending on how long the motor has been running and how much weight it has been carrying, especially for heavy-duty motors like a 20 hp dc electric motor.

When anything breaks down unexpectedly, emergency repair services are quite important. Having established ties with certified service providers reduces downtime and makes sure that repairs are done correctly.

Keeping records of maintenance work helps find issues that happen again and over again and make repair intervals more efficient. Keep thorough records of repairs, replacements, and performance measures. Training programs for maintenance workers make the whole system more reliable. Staff that are well-trained can see possible issues early and do regular maintenance tasks accurately.

Conclusion

To keep your DC motor investment working well, you need to pay close attention to its critical parts and performance indicators on a regular basis. Regular checks, correct lubrication, and timely replacement of parts keep everything running smoothly and avoid expensive breakdowns. Knowing how motors behave might help you spot issues before they affect production schedules. Professional help and high-quality replacement parts make sure that the motor works at its best for its entire service life. Following these maintenance steps can safeguard your investment and help keep your business running smoothly.

Partner with XCMOTOR for Reliable Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides comprehensive support for your industrial motor requirements. Our expertise spans manufacturing, HVAC, energy utilities, and specialized applications across diverse industries.

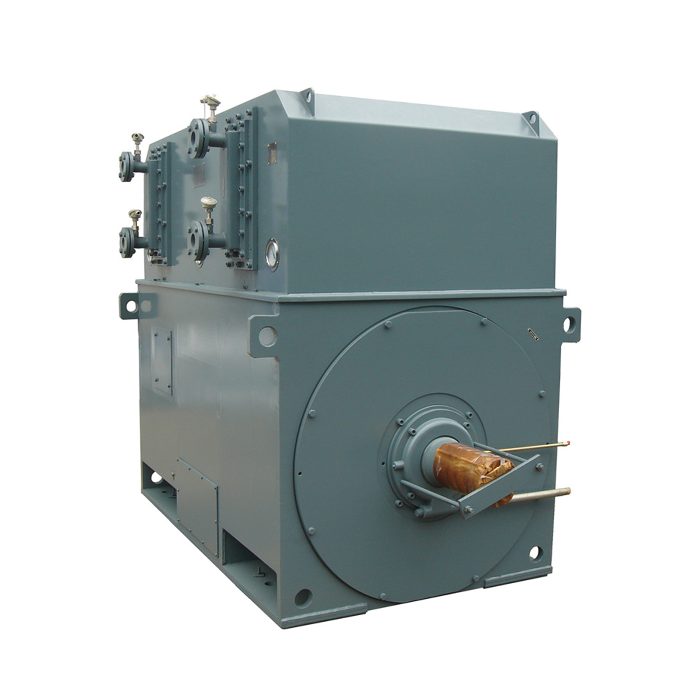

As a trusted 20 hp dc electric motor supplier, we understand the critical importance of reliable equipment in your operations. Our Z4 series motors deliver exceptional performance with power ranges from 1.5 to 600kW, featuring advanced control capabilities and robust construction.

Our commitment to quality extends beyond product delivery. We provide dedicated technical support, including weekend availability, ensuring your operations receive assistance when needed. Original components from trusted manufacturers guarantee reliable performance and extended service life.

Fast delivery services minimize equipment downtime when replacements become necessary. Our 30-day return policy demonstrates confidence in product quality while providing peace of mind for your procurement decisions.

Technical expertise accumulated through years of industry experience enables us to recommend optimal solutions for specific applications. Whether you need motors for metallurgical rolling mills, machine tools, or packaging equipment, our team understands your requirements.

Ready to discuss your motor requirements or need technical support? Contact us at xcmotors@163.com to connect with our experienced team. We're here to help optimize your equipment performance and ensure reliable operations.

References

- Chapman, Stephen J. "Electric Machinery Fundamentals." McGraw-Hill Education, 2019.

- Hughes, Austin and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications." Newnes, 2020.

- Fitzgerald, A.E., Charles Kingsley Jr., and Stephen D. Umans. "Electric Machinery." McGraw-Hill Science, 2018.

- Sen, P.C. "Principles of Electric Machines and Power Electronics." John Wiley & Sons, 2017.

- Wildi, Theodore. "Electrical Machines, Drives and Power Systems." Pearson, 2019.

- Nasar, S.A. and L.E. Unnewehr. "Electromechanics and Electric Machines." John Wiley & Sons, 2021.