Installing YFBX4 dust explosion-proof motors requires careful attention to safety protocols and specific procedures designed for hazardous environments. These specialized motors operate safely in areas where combustible dust particles may be present, making proper installation critical for both operational efficiency and personnel safety. Understanding the correct installation process ensures your motor delivers optimal performance while maintaining compliance with explosion protection standards. This comprehensive guide covers everything from pre-installation planning to final testing procedures, helping you achieve a successful motor installation that meets industry safety requirements.

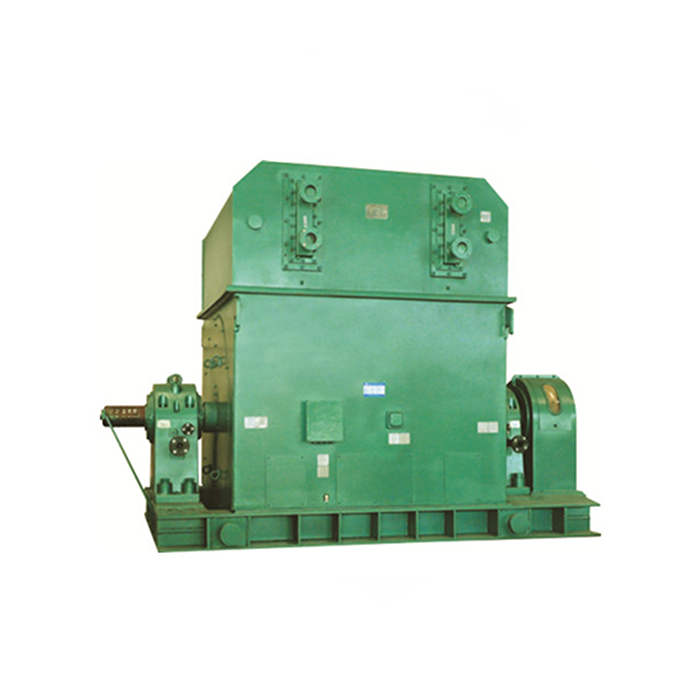

Series:YFBX4

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-315 kW

Application:medicine, textile, metallurgy, grain processing, feed processing, fertilizer, tobacco, papermaking, synthetic materials, building materials and other places where combustible dust exists.

Advantage: high efficiency, low noise, small vibration, excellent performance, safe and reliable use.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Explosion-proof mark: Ex tD A21 IP65 T 130℃, Ex tD A22 IP65 T 130℃, Ex tD A22 IP55 T 130℃".

Understanding Explosion-Proof Motor Requirements

Before starting any establishment work, understanding the principal prerequisites of explosion-proof engines becomes fundamental. The YFBX4 arrangement highlights specialized walled-in areas outlined to contain potential inner blasts and avoid the start of outside combustible environments. These engines carry explosion-proof certification markings, including Ex tD A21 IP65 T 130℃ and Ex tD A22 appraisals, demonstrating their appropriateness for clean and unsafe environments.

The motor's development incorporates a fortified cast press capable of withstanding internal pressure buildup. Fireways and joint surfaces get exact machining to anticipate fire transmission to encompassing zones. Temperature classification guarantees surface temperatures stay underneath start edges for particular tidy sorts commonly found in manufacturing facilities.

Industrial computerization frameworks, especially in chemical handling and grain taking care of offices, depend intensely on appropriate engine installation to maintain operational security. The engine with explosion-proof walls in the area must coordinate consistently with existing hardware, while protecting all defensive features.

Pre-Installation Safety Assessment

Conducting an exhaustive security evaluation anticipates establishment complications and guarantees administrative compliance. Start by recognizing the particular unsafe range classification where the engine will work. Zone 21 and Zone 22 classifications require distinctive security levels, influencing engine choice and establishment procedures.

Environmental factors significantly impact installation requirements. Ambient temperature ranges, humidity levels, and dust characteristics influence mounting decisions and protective measures. The YFBX4 dust explosion-proof motor specifications accommodate temperatures from -20°C to +40°C with altitude considerations up to 1000 meters above sea level.

Document all existing electrical associations and confirm compatibility with engine voltage prerequisites. The arrangement underpins numerous voltage setups, including 380V, 660V, 415V, 380/660V, and 660/1140V alternatives. Control prerequisites extending from 0.55kW to 315kW must coordinate application requests to anticipate over-burdening or underperformance.

Coordinate with the office security workforce to build up appropriate lockout/tagout methods. Unsafe range engine establishment requires extra security conventions beyond standard electrical work. Guarantee all group members get it blast assurance standards and crisis strategies specific to your facility.

Essential Tools and Equipment Preparation

Gathering suitable instruments and hardware streamlines the establishment prepare while keeping up security measures. Explosion-proof establishments require specialized devices appraised for dangerous situations. Standard instruments may produce sparks or warm that might ignite combustible atmospheres.

Lifting gear must oblige engine weight and dimensional requirements. Bigger YFBX4 units require mechanical lifting help due to their strong development. Arrange lifting courses carefully to maintain a safe distance from harm to engine-walled-in areas or encompassing equipment.

Electrical testing gear ought to incorporate separator resistance analyzers, multimeters appraised for unsafe ranges, and establishing confirmation instruments. These rebellious offer assistance to confirm the legitimate establishment some sometimes recently energizing the engine system.

Torque torques guarantee legitimate clasp fixing without harming explosion-proof joints. Over-tightening can mutilate fire ways, whereas under-tightening may compromise security judgment. Producer details give correct torque values for diverse association points.

Cleaning supplies particularly designed for evacuating tidy, flotsam, and debris from engine surfaces are fundamental. Defilement of fireways or joint surfaces can compromise blast assurance viability. Utilize, as it were, approved solvents and cleaning strategies in perilous environments.

Step-by-Step Motor Installation Process

Begin installation by verifying motor nameplate information matches application requirements. Check voltage ratings, power output, speed characteristics, and explosion protection markings. Any discrepancies require resolution before proceeding with installation.

Position the motor carefully using appropriate lifting techniques. Align mounting surfaces precisely to prevent stress on the motor frame. Uneven mounting can cause vibration issues that reduce bearing life and overall performance. The motor's design incorporates dynamic balancing to minimize vibration, but proper mounting remains critical.

Secure mounting bolts following the manufacturer's torque specifications. Begin with finger-tight installation, then gradually tighten in a cross pattern to ensure even stress distribution. This approach prevents warping of mounting surfaces that could affect alignment.

Connect electrical supply cables using proper explosion-proof fittings. All cable entries must maintain the YFBX4 dust explosion-proof motor's protection rating through appropriate sealing methods. Cable glands and conduit fittings require proper installation to prevent dust ingress or compromise of explosion protection.

Verify grounding connections meet local electrical codes and explosion protection standards. Proper grounding provides both electrical safety and static electricity dissipation in dusty environments. Use dedicated grounding conductors sized according to motor current ratings.

Install any required auxiliary equipment, such as temperature sensors or vibration monitors. These devices help monitor motor health and prevent failures that could create safety hazards in dust explosion-proof applications.

Electrical Connections and Safety Verification

Electrical connection procedures for industrial explosion-proof motors demand meticulous attention to detail. Start by verifying power supply characteristics match motor requirements. Phase sequence, voltage levels, and frequency must align with motor specifications to prevent damage or poor performance.

Use only approved cable types rated for hazardous environments. Cable insulation must withstand exposure to dust, moisture, and temperature variations typical in industrial settings. Armored cables provide additional protection against mechanical damage in harsh environments.

Junction boxes and terminal connections require special consideration in industrial hazardous environments. All electrical enclosures must maintain appropriate protection ratings. Clean all connection points thoroughly before making final connections to ensure reliable electrical contact.

Perform insulation resistance testing before energizing the motor. This test verifies winding integrity and identifies potential moisture or contamination issues. Insulation resistance values should meet or exceed manufacturer specifications for safe operation.

Test ground fault protection systems and emergency shutdown circuits. These safety systems provide critical protection in hazardous environments where motor failures could create dangerous conditions. Verify all safety interlocks function properly before placing the motor in service.

Document all electrical connections and test results for future maintenance reference. Proper documentation supports troubleshooting efforts and helps maintain compliance with safety regulations.

Post-Installation Testing and Commissioning

Comprehensive testing validates proper installation and ensures safe operation in dust explosion environments. Begin with visual inspections of all connections, mounting hardware, and protection systems. Look for any signs of damage or improper installation that could compromise safety or performance.

Conduct motor rotation tests to verify correct direction and smooth operation. Many applications require a specific rotation direction for proper equipment function. Incorrect rotation can damage driven equipment or create unsafe operating conditions.

Measure operating temperatures during initial startup to establish baseline performance data. Temperature monitoring helps identify potential problems before they cause equipment failure. The motor for combustible dust applications must maintain surface temperatures below ignition thresholds.

Monitor vibration levels during operation to verify proper installation and alignment. Excessive vibration indicates mounting or alignment issues that require immediate attention. The YFBX4 dust explosion-proof motor design minimizes vibration through precision manufacturing and dynamic balancing.

Test all protection and monitoring systems under actual operating conditions. Emergency shutdown systems, temperature monitoring, and other safety devices must function reliably in the intended environment. Document all test results for maintenance records and regulatory compliance.

Gradually increase load to full operating conditions while monitoring motor performance. This approach identifies any issues before they affect production operations. Full load testing validates that the installation meets the application requirements.

Maintenance Considerations for Optimal Performance

Regular maintenance preserves explosion protection integrity while maximizing motor reliability. Develop a maintenance schedule based on operating conditions and manufacturer recommendations. Harsh environments may require more frequent inspections than clean industrial applications.

- Inspect explosion-proof joints and flame paths regularly for damage or contamination. Dust accumulation on these surfaces can compromise protection effectiveness. Clean joints carefully using approved methods that won't damage precision-machined surfaces.

- Monitor bearing performance through vibration analysis and temperature measurements. The YFBX4 series accommodates premium bearings from SKF, NSK, or FAG according to customer requirements. Proper lubrication and monitoring extend bearing life significantly.

- Keep detailed maintenance records documenting all inspections, repairs, and component replacements. These records support warranty claims and help identify patterns that could indicate systematic issues requiring attention.

- Train maintenance personnel on explosion protection principles and proper service procedures. Working on motors in hazardous environments requires specialized knowledge and safety precautions beyond standard electrical maintenance.

- Stock critical spare parts to minimize downtime when maintenance becomes necessary. Motors operating in challenging environments may require more frequent component replacement than those in benign applications.

Conclusion

Proper establishment of YFBX4 explosion-proof engines requires careful consideration of security conventions, specialized determinations, and natural considerations. Victory depends on exhaustive pre-installation planning, exact execution of installation procedures, and comprehensive testing some sometimes recently commissioning. The venture in appropriate establishment pays profits through dependable operation, upgraded security, and extended hardware life in challenging mechanical situations. Taking after producer rules, while adjusting to particular location conditions, guarantees ideal execution and administrative compliance. With legitimate establishment and progressing support, these strong engines give tried and true benefit in requesting applications where security cannot be compromised.

Partner with XCMOTOR for Professional Installation Support

Choosing the right YFBX4 dust explosion-proof motor supplier makes a significant difference in installation success and long-term performance. XCMOTOR specializes in providing comprehensive power equipment solutions designed specifically for hazardous industrial environments. Our experienced team understands the unique challenges of installing explosion-proof motors in manufacturing facilities, process control applications, and other demanding industrial settings. XCMOTOR offers extensive YFBX4 motor inventory, fast delivery, weekend technical support, a 30-day return policy, and guidance on dust ignition protection, ensuring safe, reliable, and well-maintained equipment.

Ready to enhance your facility's safety and performance with properly installed explosion-proof motors? Contact our technical specialists to discuss your specific requirements and learn how XCMOTOR can support your installation project from start to finish. Reach out to us at xcmotors@163.com to schedule a consultation and discover why leading manufacturers trust XCMOTOR for their critical power equipment needs.

References

1. National Electrical Code (NEC) Handbook, Article 500-506: Hazardous Locations, National Fire Protection Association, 2023 Edition

2. IEC 60079-0:2017 Explosive atmospheres - Part 0: Equipment - General requirements, International Electrotechnical Commission

3. IEEE Standard 1349-2011: IEEE Guide for Application of Electric Motors in Class I, Division 2 and Zone 2 Hazardous Locations

4. NFPA 499: Recommended Practice for the Classification of Combustible Dusts and of Hazardous Locations for Electrical Installations in Chemical Process Areas

5. API RP 500: Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class I, Division 1 and Division 2

6. IEC 60034-1:2017 Rotating electrical machines - Part 1: Rating and performance, International Electrotechnical Commission