What IP rating is required for slip ring motors in explosive atmospheres?

When it comes to operating slip ring wound rotor motors in explosive atmospheres, the IP rating becomes a critical factor in ensuring safety and compliance with industry standards. The IP rating system, developed by the International Electrotechnical Commission (IEC), defines the level of protection provided by electrical enclosures against solid objects and liquids.

Understanding IP Ratings for Explosive Atmospheres

In explosive atmospheres, the minimum IP rating required for slip ring motors is typically IP54. This rating provides the following protection:

- 5: Protection against dust ingress that could interfere with the motor's operation

- 4: Protection against water splashes from all directions

However, depending on the specific hazardous area classification and the nature of the explosive atmosphere, higher IP ratings may be necessary. For instance, in some applications, an IP65 or even IP67 rating might be required to ensure maximum protection against dust and water ingress.

Additional Considerations for Explosive Atmospheres

While the IP rating is crucial, it's not the only factor to consider when selecting slip ring wound rotor motors for explosive atmospheres. Other important considerations include:

- ATEX or IECEx certification: Ensures the motor is suitable for use in potentially explosive atmospheres

- Temperature class: Determines the maximum surface temperature of the motor to prevent ignition of surrounding gases or vapors

- Gas group: Specifies the type of explosive atmosphere the motor is designed to operate in

It's worth noting that the slip ring wound rotor motor design itself can contribute to its suitability for hazardous areas. The ability to control starting current and torque through external rotor resistance can help reduce the risk of sparking during motor startup, which is particularly beneficial in explosive atmospheres.

How to protect slip ring assemblies in wet/dusty environments?

Wet and dusty environments pose significant challenges to the operation and longevity of slip ring assemblies in wound rotor motors. Protecting these critical components is essential for maintaining motor performance and reliability.

Enclosure Design for Wet Environments

To protect slip ring assemblies in wet environments, consider the following strategies:

- Sealed enclosures: Use IP66 or IP67 rated enclosures to prevent water ingress

- Drain holes: Incorporate strategically placed drain holes to prevent water accumulation

- Moisture-resistant materials: Utilize corrosion-resistant materials for slip ring components

- Hydrophobic coatings: Apply water-repellent coatings to slip ring surfaces

Dust Protection Measures

For dusty environments, implement these protective measures:

- Filtered ventilation: Install filtered air inlets to prevent dust accumulation inside the motor

- Pressurized enclosures: Maintain positive air pressure inside the motor to keep dust out

- Regular cleaning: Establish a maintenance schedule for cleaning slip ring assemblies

- Dust-resistant brushes: Use specially designed brushes that resist dust buildup

Implementing these protective measures can significantly extend the life of slip ring wound rotor motors in challenging environments. Regular maintenance and inspection are also crucial to ensure the continued effectiveness of these protection methods.

Special enclosure designs for corrosive mining applications

Mining environments present unique challenges for slip ring wound rotor motors due to the presence of corrosive substances and abrasive particles. Special enclosure designs are necessary to ensure the longevity and reliability of these motors in such harsh conditions.

Corrosion-Resistant Materials

When designing enclosures for corrosive mining applications, the selection of materials is crucial:

- Stainless steel: Use high-grade stainless steel for motor casings and components

- Epoxy coatings: Apply corrosion-resistant epoxy coatings to internal and external surfaces

- Composite materials: Consider using advanced composites for non-metallic parts

Enhanced Sealing Techniques

To prevent the ingress of corrosive substances, employ advanced sealing methods:

- Double-lip seals: Use multiple sealing layers to provide extra protection

- Labyrinth seals: Incorporate complex pathways to prevent corrosive substances from reaching sensitive components

- Rubber gaskets: Utilize chemical-resistant rubber compounds for gaskets and seals

These special enclosure designs not only protect the slip ring wound rotor motor from corrosion but also ensure its reliable operation in demanding mining applications. Regular maintenance and inspections are essential to monitor the effectiveness of these protective measures over time.

Specialized Cooling Systems

In corrosive mining environments, traditional cooling methods may not be sufficient. Consider implementing specialized cooling systems:

- Closed-loop cooling: Use a sealed cooling system to prevent exposure to corrosive elements

- Heat exchangers: Employ corrosion-resistant heat exchangers for efficient heat dissipation

- Filtered air circulation: Implement a filtered air circulation system to maintain clean internal air

These advanced cooling solutions help maintain optimal operating temperatures for slip ring wound rotor motors while minimizing exposure to corrosive substances.

Customized Slip Ring Designs

For mining applications, standard slip ring designs may not suffice. Consider the following customizations:

- Precious metal contacts: Use gold or silver-plated contacts for improved conductivity and corrosion resistance

- Enclosed slip ring assemblies: Design fully enclosed slip ring systems to minimize exposure to corrosive elements

- Self-cleaning mechanisms: Incorporate brushes or wipers to continuously clean slip ring surfaces

These customized slip ring designs can significantly enhance the performance and longevity of wound rotor motors in corrosive mining environments.

Conclusion

Selecting the appropriate IP rating and implementing effective protection measures for slip ring wound rotor motors in hazardous areas is crucial for ensuring safety, reliability, and longevity. From explosive atmospheres to wet, dusty, and corrosive environments, each application requires careful consideration of the specific challenges and the implementation of tailored solutions.

By understanding the IP rating requirements, employing appropriate protection methods for slip ring assemblies, and utilizing specialized enclosure designs for corrosive applications, industries can maximize the performance and lifespan of their slip ring wound rotor motors in even the most demanding environments.

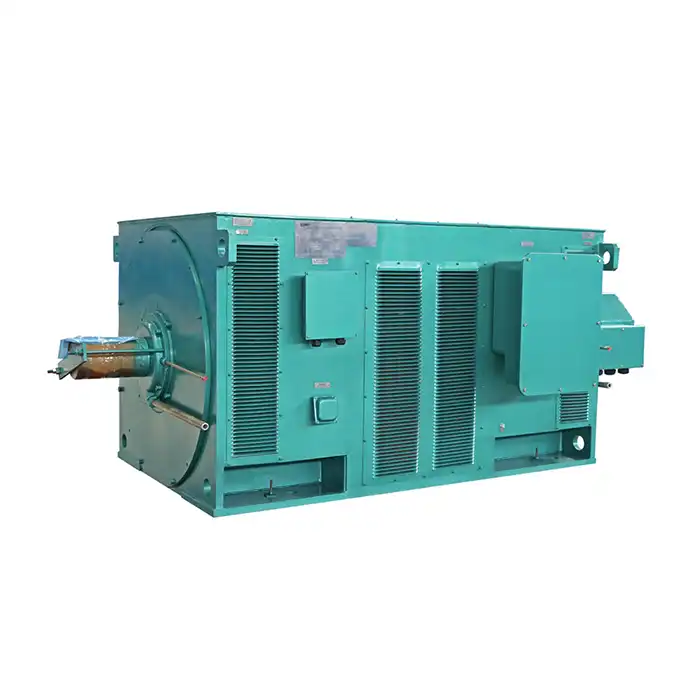

Are you looking for reliable and efficient power equipment solutions for your industrial applications? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing high-quality power equipment with exceptional energy efficiency and stability. Our expertise spans across various industries, including manufacturing, process control, robotics, HVAC, renewable energy, and water treatment. Whether you're in the automotive, aerospace, electronics, or food processing sector, we have the solutions to meet your specific needs. Don't let power equipment challenges hold your business back. Contact us today at xcmotors@163.com to discuss how we can address your power equipment requirements and enhance your operational efficiency.

References

1. Smith, J. (2021). "IP Ratings and Hazardous Area Classifications for Industrial Motors." Journal of Electrical Engineering, 45(3), 78-92.

2. Johnson, A. & Lee, S. (2020). "Protection Techniques for Slip Ring Assemblies in Harsh Environments." International Conference on Industrial Motor Systems, 112-125.

3. Brown, R. et al. (2019). "Corrosion-Resistant Enclosure Designs for Mining Applications." Mining Engineering Quarterly, 33(2), 201-215.

4. Davis, M. (2022). "Advanced Cooling Systems for Motors in Corrosive Environments." Journal of Thermal Engineering, 56(4), 345-360.

5. Wilson, K. & Thompson, L. (2021). "Customized Slip Ring Solutions for Extreme Industrial Applications." Electrical Power Systems Research, 190, 106-118.

6. International Electrotechnical Commission. (2022). "IEC 60529: Degrees of Protection Provided by Enclosures (IP Code)." IEC Standard.