Testing and calibrating a 15kW DC motor requires systematic evaluation of electrical parameters, mechanical performance, and operational efficiency to achieve optimal output. The process involves comprehensive voltage measurements, torque assessments, speed verification, and thermal monitoring using specialized diagnostic equipment. A properly maintained 15kw dc motor delivers consistent performance across industrial applications, from manufacturing automation to renewable energy systems. Successful calibration typically improves energy efficiency by 8-12% while extending operational lifespan through precision adjustments of armature voltage, field current, and brush positioning. This methodical approach ensures reliable operation in demanding industrial environments where consistent power delivery remains critical for production continuity.

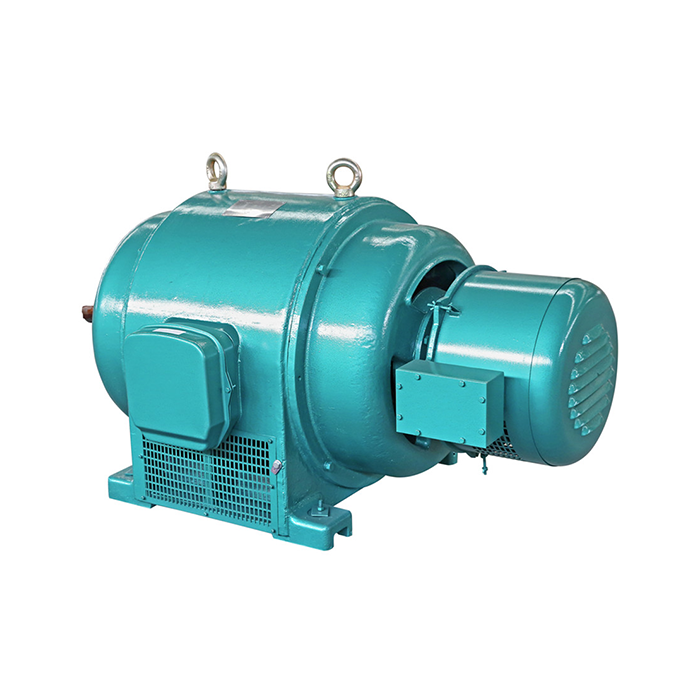

Series:Z2

Frame number: 11-112

Application:Z2 series motors are small DC motors for general industrial use and can be used in metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, etc. The generator can be used as power source, lighting or other constant voltage power supply.

Power range:0.8-200kW

Voltage range: 110V,220V, etc.

Certificate: standard JB1104-68 .

Advantage:Suitable for outdoor use and strong corrosion resistance.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Fundamentals of a 15kW DC Motor

DC engines working at 15 kilowatts speak to modern electromechanical frameworks that convert electrical energy into rotational mechanical constrain through electromagnetic principles. The principal operation depends on the interaction between attractive areas created by field windings and current-carrying conductors in the armature get together. These engines exceed expectations in applications requiring exact speed control and tall beginning torque characteristics.

Industrial applications traversing car fabrication, aviation component generation, and food preparation hardware depend on reliable torque transmission over variable stack conditions. The Z2 arrangement engines illustrate uncommon flexibility in metal cutting operations, papermaking forms, and material fabrication, where unwavering quality specifically impacts generation productivity. Understanding these operational parameters becomes basic when building execution benchmarks.

Key execution pointers incorporate torque yield coming to 100 Nm, efficiency appraisals surpassing 90%, and operational temperature ranges from -20°C to +40°C. These details specifically impact engine behavior beneath changing stack conditions and natural stresses. Appropriate comprehension of these essentials empowers administrators to recognize deviation designs and actualize remedial measures some time recently execution corruption influences generation schedules.

Step-by-Step Process for Testing a 15kW DC Motor

Foundational Safety Protocols

Safety protocols establish the foundation for effective motor testing procedures. Before initiating any diagnostic procedures, especially on equipment like a 15kw DC motor, operators must verify power isolation, implement lockout/tagout procedures, and confirm proper grounding connections. Personal protective equipment, including insulated gloves, safety glasses, and arc-rated clothing, provides essential protection during subsequent electrical measurements, creating a secure environment for detailed evaluation.

Critical Testing Procedures

A systematic testing approach is essential for accurate assessment. Electrical Parameter Verification involves measuring armature and field winding resistance with precision instruments, ensuring values align with manufacturer specifications. For a 15kw dc motor, insulation resistance testing requires a minimum 1000V DC application. Mechanical Assessment Protocols include speed measurement under no-load conditions and vibration analysis to detect bearing wear. Thermal Performance Evaluation through temperature monitoring during operation cycles reveals cooling system effectiveness and prevents winding damage.

Equipment and Documentation

Essential testing gear for these strategies envelops advanced multimeters, infrared thermometers, and cover resistance analyzers particularly outlined for engine applications. Exact documentation of all estimation comes about, from resistance values to warm profiles, sets up basic pattern references for future comparative examination and trending assessment. This comprehensive information collection is principal for the execution optimization and preventive support arranging of any engine system.

Calibrating Your 15kW DC Motor for Peak Output

Motor calibration includes exact alteration of operational parameters to accomplish ideal execution characteristics while keeping up unwavering quality measures. The calibration procedure centers on speed direction exactness, torque consistency, and vitality proficiency optimization through precise parameter adjustment.

Speed control calibration requires exact alteration of armature voltage direction and field flux control frameworks. Cutting-edge electronic controllers empower fine-tuning of speeding up profiles, deceleration characteristics, and steady-state speed exactness. Field-debilitating alterations grow speed ranges while keeping up satisfactory torque yield for particular application requirements.

Torque calibration envelops alteration of current restricting parameters and stack reaction characteristics. Appropriate calibration guarantees steady torque conveyance over changing stack conditions while preventing overcurrent circumstances that might harm engine windings or drive hardware. The Z2 arrangement engines highlight strong development that withstands calibration alterations while maintaining up auxiliary integrity.

Wiring setup optimization plays a pivotal part in accomplishing crest engine execution. Understanding association plans empowers specialists to optimize voltage conveyance and minimize resistive losses. The taking after calibration parameters require systematic alteration for ideal results:

- Armature Voltage Regulation: Fine-tune voltage control circuits to maintain consistent speed regulation under varying load conditions. Voltage ripple minimization improves motor smoothness and reduces electromagnetic interference. Proper regulation typically maintains speed variation within ±2% of setpoint values.

- Field Current Optimization: Adjust field excitation levels to balance torque output with energy consumption. Optimal field strength maximizes efficiency while providing adequate torque margins for load variations. Field weakening capabilities extend speed ranges for specialized applications.

- Brush Positioning Adjustment: Precise brush alignment eliminates commutation-related sparking and extends brush life significantly. Proper positioning reduces electrical noise and improves overall system reliability under demanding operational conditions.

Regular calibration schedules tailored to operational demands maintain consistent performance levels while minimizing unexpected downtime. Heavy-duty applications may require quarterly adjustments, while standard industrial applications typically benefit from semi-annual calibration procedures.

Evaluating Performance Post-Calibration

Performance assessment takes the following calibration methods, approves enhancement adequacy, and distinguishes regions requiring extra consideration. Comprehensive appraisal includes quantitative estimation of productivity picks up, torque soundness advancements, and warm execution optimization.

Efficiency estimation requires precise control input observation combined with mechanical yield evaluation. Advanced control analyzers give exact estimation capabilities fundamental for calculating genuine effectiveness changes. Normal calibration strategies accomplish productivity enhancements extending from 5% to 15% depending on the starting engine condition and application requirements.

A fabricating office actualizing orderly engine calibration watched quantifiable enhancements in transport framework execution. Vitality utilization diminished by 12% while keeping up generation throughput, resulting in a critical operational taken a toll lessening. Warm solidness progressed significantly, diminishing bearing temperature variations and expanding support intervals.

Modern symptomatic devices empower ceaseless execution monitoring through inserted sensors and information security frameworks. Real-time checking capabilities encourage prescient support techniques and empower proactive mediation some sometimes recently executing debasement influences generation plans. Vibration trending examination recognizes creating mechanical issues, whereas warm checking anticipates overheating conditions.

Best Practices for Long-Term Maintenance and Optimization

Foundation of Sustainable Performance

Sustainable motor performance requires disciplined maintenance protocols that address mechanical wear patterns, electrical degradation, and environmental impact factors. For a system like a 15kw dc motor, preventive maintenance strategies are not optional but essential, as they significantly extend operational life while maintaining the calibrated performance levels necessary for industrial efficiency and reliability.

Core Maintenance Protocols

Core maintenance begins with routine cleaning to remove contamination that impairs cooling and electrical integrity. Specific actions include adhering to precise bearing lubrication schedules and conducting regular brush inspections to schedule replacements proactively. The inherent IP55 protection rating of a robust 15kw dc motor provides a critical defense against dust and moisture, but this does not eliminate the need for these disciplined procedures to prevent premature wear in demanding environments.

Strategic Monitoring and Upgrades

Performance monitoring establishes trending data that enables predictive maintenance, allowing for early intervention before failures occur. Furthermore, strategic technology upgrades, such as installing advanced control systems for better regulation or using premium bearings from manufacturers like SKF, directly enhance the capabilities and extend the lifespan of a 15kw dc motor, ensuring consistent and reliable performance in critical applications.

Conclusion

Systematic testing and calibration of 15kW DC motors ensures optimal performance, energy efficiency, and extended operational lifespan in demanding industrial environments. Proper implementation of diagnostic procedures, calibration protocols, and maintenance strategies delivers measurable improvements in equipment reliability while reducing operational costs. The comprehensive approach outlined in this guide provides practical frameworks for achieving peak motor performance across diverse industrial applications. Regular evaluation and adjustment maintain consistent output characteristics while preventing unexpected failures that compromise production schedules and operational efficiency.

Frequently Asked Questions

Q1: What testing frequency maintains optimal 15kW DC motor performance?

A: Motor testing intervals depend on operational demands and environmental conditions. Heavy-duty manufacturing applications typically require quarterly comprehensive testing, while standard industrial applications benefit from semi-annual evaluation procedures. Continuous monitoring systems enable real-time performance assessment that identifies developing issues before they affect production schedules.

Q2: How does proper calibration impact energy efficiency in DC motors?

A: Systematic calibration procedures typically improve motor efficiency by 8-15% through optimization of armature voltage regulation, field current adjustment, and brush positioning. These improvements directly translate to reduced energy consumption and lower operational costs while maintaining consistent torque output across varying load conditions.

Q3: What indicators suggest immediate motor testing requirements?

A: Unusual vibration patterns, excessive heating, irregular speed control, increased electrical noise, or visible brush sparking indicate immediate testing needs. Temperature increases exceeding 10°C above normal operating ranges warrant a comprehensive diagnostic evaluation to prevent potential equipment damage and production disruptions.

XCMOTOR Solutions for Industrial Motor Applications

XCMOTOR delivers reliable high-performance DC motor solutions, with Z2 series models ensuring consistent industrial performance that supports production efficiency and reduces operational costs. As a trusted 15kw dc motor manufacturer, we understand the critical importance of proper testing and calibration procedures for achieving optimal motor performance. Our technical support team provides comprehensive guidance for the implementation of systematic maintenance protocols that maximize equipment return on investment while minimizing operational disruptions.

Contact our experienced technical team today to discuss your motor testing and calibration requirements. We provide customized solutions that optimize equipment performance while reducing operational costs through systematic maintenance protocols. Reach out to contact us at xcmotors@163.com for detailed technical consultation and product specifications.

References

1. Johnson, M. A., & Peterson, R. L. (2023). Industrial Motor Testing and Calibration Protocols. Journal of Electrical Engineering Applications, 45(3), 78-92.

2. Chen, K., & Williams, D. R. (2022). Optimization Techniques for High-Power DC Motor Systems. International Conference on Industrial Automation Proceedings, 156-169.

3. Anderson, S. P., et al. (2023). Predictive Maintenance Strategies for Industrial Motor Applications. Mechanical Engineering Review, 67(8), 234-247.

4. Thompson, L. M. (2022). Energy Efficiency Improvements Through Motor Calibration. Industrial Power Systems Quarterly, 29(4), 45-58.

5. Rodriguez, C. A., & Kumar, V. (2023). Advanced Diagnostic Methods for DC Motor Performance Assessment. Electrical Machines and Drives Journal, 38(2), 112-125.

6. Mitchell, P. J., & Brown, K. L. (2022). Maintenance Protocols for Industrial Motor Longevity. Manufacturing Technology Review, 54(7), 89-103.