Retrofitting old industrial equipment with IE4 induction motors begins with a systematic assessment of your existing motor installations and identifying compatibility requirements for high-efficiency replacements. To guarantee smooth integration, power standards, mounting arrangements, and electrical connections are evaluated. Modern IE4 induction motor technology saves up to 96% energy, making retrofitting an appealing investment for industrial enterprises aiming to save costs while fulfilling environmental and regulatory criteria.

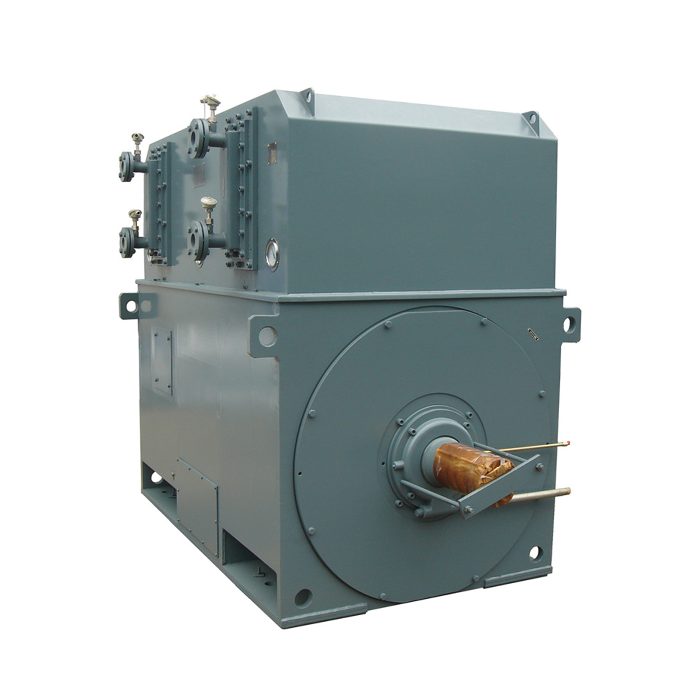

Series:YE4

Frame number: 80-450

Power range:0.75-1000kW

Protection level:IP55

Energy efficiency class: IE4

Voltage range: 380V,400V,415V, 660V,etc.

Application:can be used in various fields of the national economy, such as machine tools,water pumps,fans,compressors,and can also be used in transportation, mixing, printing, agricultural machinery, food and other occasions that do not contain flammable, explosive or corrosive gases.

Certificate: international standard IEC60034-30 ""Efficiency Classification of Single-speed Three-Phase Squirrel Cage Induction Motors"".

Advantage:The high quality of the electric motor guarantees high operational reliability.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding the Need for Retrofitting Old Motors with IE4 Induction Motors

Industrial offices over-fabricating, HVAC, and vitality segments continue working with obsolete engine frameworks that expend over the top vitality and produce higher maintenance costs. These bequest engines ordinarily work at IE1 or IE2 proficiency levels, squandering profitable assets while battling to meet current environmental directions forced by government and state authorities.

The Hidden Costs of Outdated Motor Technology

Older engines at IE1 or IE2 productivity squander vitality, increment support, and create higher power bills, whereas rising vitality costs and administrative weights make operational costs and compliance challenges significant.

Overcoming Retrofit Hesitation Through Strategic Planning

Proper planning, compatibility evaluation, and IE4 induction motor payback times enable firms justify retrofits, reduce installation hazards, and maximise energy savings and operational efficiency.

Core Benefits and Technical Advantages of IE4 Induction Motors in Retrofitting

High-efficiency engine innovation conveys quantifiable execution changes that amplify past basic vitality investment funds. IE4 classification speaks to the most elevated standard for three-phase squirrel cage acceptance engines, advertising proficiency picks up of 2-5% over IE3 models and essentially higher execution compared to IE1 or IE2 systems.

Advanced Engineering Features Driving Performance

IE4 induction motors feature optimized windings, premium magnetic materials, and improved thermal management, delivering superior torque, stable operation, reduced vibration, and noise, with wide voltage and power range compatibility for industrial retrofits.

Quantifiable Economic Impact

Retrofit with IE4 induction motors reduces energy consumption, lowers maintenance costs, and improves power factor, providing long-term financial benefits while ensuring reliable, high-performance operation in demanding industrial environments.

Step-by-Step Process to Retrofit Old Equipment with IE4 Induction Motors

Motor retrofitting needs careful planning and execution to maximise outcomes and minimise downtime. An comprehensive review of current equipment is followed by performance testing to ensure predicted advantages.

Pre-Retrofit Evaluation and Planning

Evaluating current equipment for IE4 induction motor compatibility documents power, mounting, shaft, and electrical characteristics and analyses duty cycles, load, and climatic variables to optimise motor selection and installation demands.

Top Installation Tips and Technical Considerations

IE4 induction motor installation needs perfect mechanical alignment, electrical integration, and commissioning, including vibration, thermal, and efficiency tests, for dependable operation and long-term performance in retrofitted equipment.

Optimisation and Verification After Installation

Performance evaluation of the IE4 induction motor after installation validates efficiency advantages, mechanical stability, and energy savings, providing baseline data for monitoring, maintenance planning, and long-term operational optimisation.

Comparing IE4 Induction Motors with Alternatives for Retrofitting Decisions

Efficiency ratings, lifespan costs, and application requirements must be considered while choosing motor technology. In most industrial applications, IE4 motors outperform previous efficiency classifications.

Economic Analysis and Efficiency Class Comparison

IE1–IE4 efficiency classifications enhance energy performance and operating expenses significantly. At full load, IE4 motors are 96% efficient, compared to 92-94% for IE3 and 87-91% for IE2. These changes result in significant energy savings during equipment lifespan.

Economic research shows that energy savings repay IE4 motors' higher startup price within 2-4 years. When equipment runs frequently, high-efficiency motors provide a lower total cost of ownership, especially in applications with high duty cycles or high electricity rates.

Technology and Application Options

Synchronous and brushless motor technologies provide benefits in some applications but may not be best for industrial retrofits. Most pump, fan, compressor, and material handling applications benefit from IE4 induction motors. Their durability and dependability make them appropriate for harsh industrial situations.

Application-specific factors influence motor selection decisions beyond simple efficiency ratings. Variable speed requirements may benefit from integrated drive solutions, while high-precision applications might require servo technology. However, the majority of industrial motor applications find excellent performance and value with IE4 induction motors.

Procurement teams benefit from understanding these technology options to make informed decisions that balance performance requirements with budget constraints. Real-world case studies demonstrate successful IE4 motor installations across diverse industries, providing confidence in technology selection and expected outcomes.

Procuring IE4 Induction Motors: What B2B Buyers Need to Know

Motor procurement involves multiple considerations beyond technical specifications, including supplier evaluation, delivery logistics, and ongoing support requirements. Understanding these factors helps procurement teams secure optimal solutions while managing project timelines and budgets effectively.

Supplier Evaluation and Selection Criteria

Reliable suppliers provide comprehensive support throughout the procurement and installation process, from initial consultation through ongoing maintenance requirements. Key evaluation criteria include technical expertise, product quality, delivery capabilities, and after-sales support services. Established suppliers offer proven track records with documented customer satisfaction and successful project completions.

Quality certifications and compliance standards verify that motors meet international requirements for safety, performance, and efficiency. CE marking and IEC compliance ensure products satisfy regulatory requirements while providing consistent performance characteristics. Premium bearing options from recognized manufacturers enhance reliability and extend service intervals.

Procurement Strategy and Cost Management

Bulk obtaining openings can give critical investment funds for multi-motor retrofit ventures, while guaranteeing reliable decisions over establishments. Custom engine setups may be accessible for special applications, permitting optimization of execution characteristics for particular working conditions. Understanding lead times and stock accessibility makes a difference oversee extend plans and maintaining a distance from expensive delays.

Warranty scope and specialized bolster administrations give important security for engine speculations whereas guaranteeing ideal long-term execution. Comprehensive back incorporates establishment direction, investigating help, and support proposals that amplify gear life and keep up effectiveness gains.

The obtainment handle benefits from clear communication of application necessities and execution desires. Experienced providers can prescribe ideal engine setups whereas distinguishing potential investment funds through standardization or volume obtaining arrangements.

Conclusion

Retrofitting industrial equipment with IE4 induction motor represents a vital speculation that conveys significant energy savings, diminished upkeep costs, and made strides operational unwavering quality. The efficient approach laid out in this direct makes a difference acquirement groups explore specialized contemplations whereas maximizing return on investment through appropriate planning and execution. High-efficiency engine innovation gives quantifiable benefits over assorted mechanical applications, making retrofit ventures appealing for companies looking to progress competitiveness whereas assembly natural objectives.

FAQ

1. What makes IE4 motors superior to IE3 efficiency class motors?

IE4 motors achieve higher efficiency ratings through advanced design features including premium magnetic materials, optimized winding configurations, and improved thermal management systems. These motors typically deliver 2-5% additional energy savings compared to IE3 models while providing superior torque characteristics and power factor performance. The enhanced efficiency translates into lower electricity consumption and reduced operational costs over the motor's service life.

2. How do I determine compatibility between IE4 motors and existing equipment?

Compatibility evaluation requires assessment of mounting setups, shaft measurements, electrical details, and control framework necessities. Key components incorporate control appraisals, voltage requirements, speed characteristics, and natural security needs. Proficient specialized assessment makes a difference recognize any adjustments required for appropriate establishment, while guaranteeing ideal execution integration with existing hardware and control systems.

3. What is the typical payback period for IE4 motor retrofit projects?

Payback periods regularly run from 2 to 4 years, depending on operational hours, power costs, and effectiveness advancements accomplished. Engines working more than 8 hours every day in high-energy taken a toll districts regularly give speedier payback through gathered vitality reserve funds. The calculation ought to incorporate vitality fetched decreases, upkeep investments, and any utility motivations available for proficiency improvements.

4. Can IE4 motors operate with existing variable frequency drives?

Most IE4 engines are consistent with standard variable recurrence drives, in spite of the fact that legitimate measuring and setup confirmation are basic. The motors' made strides effectiveness characteristics may require drive parameter alterations to optimize execution. Proficient assessment guarantees appropriate integration whereas maximizing productivity picks up and keeping up dependable operation over the full speed range.

Transform Your Operations with XCMOTOR's IE4 Induction Motor Solutions

XCMOTOR specializes in delivering high-efficiency motor solutions designed specifically for retrofitting industrial equipment across manufacturing, HVAC, and energy sectors. Our comprehensive IE4 induction motor range spans 0.75kW to 1000kW with multiple voltage options including 380V, 400V, 415V, and 660V configurations, to match your existing infrastructure requirements.

As a trusted ie4 induction motor supplier, we provide complete retrofit support including technical consultation, custom specifications, and expert installation guidance. Our motors achieve up to 96% efficiency while maintaining IP55 protection standards suitable for demanding industrial environments. Premium bearing options from SKF, NSK, and FAG ensure optimal reliability and extended service life tailored to your specific operating conditions. Our commitment to customer success includes fast delivery with free shipping, 30-day returns, and dedicated support available seven days per week. Contact XCMOTOR at xcmotors@163.com to discuss your retrofit project and discover how our proven motor technology can reduce energy costs, improve operational reliability, and support your sustainability goals.

References

1. International Electrotechnical Commission. "IEC 60034-30-1: Rotating electrical machines - Part 30-1: Efficiency classes of line operated AC motors." Geneva: IEC Publications, 2021.

2. U.S. Department of Energy. "Premium Efficiency Motor Selection and Application Guide: A Handbook for Industry." Washington, DC: Office of Energy Efficiency and Renewable Energy, 2020.

3. European Commission. "Commission Regulation (EU) 2019/1781: Ecodesign requirements for electric motors and variable speed drives." Official Journal of the European Union, Brussels, 2019.

4. National Institute of Standards and Technology. "Energy Efficiency Standards for Industrial Motor Systems: Technical Assessment and Implementation Guidelines." Gaithersburg, MD: NIST Special Publication, 2022.

5. American Council for an Energy-Efficient Economy. "Industrial Motor Efficiency Programs: Best Practices and Lessons Learned from Utility and Government Initiatives." Washington, DC: ACEEE Research Report, 2021.

6. Institute of Electrical and Electronics Engineers. "IEEE Standard 112: Test Procedure for Polyphase Induction Motors and Generators." New York: IEEE Standards Association, 2020.