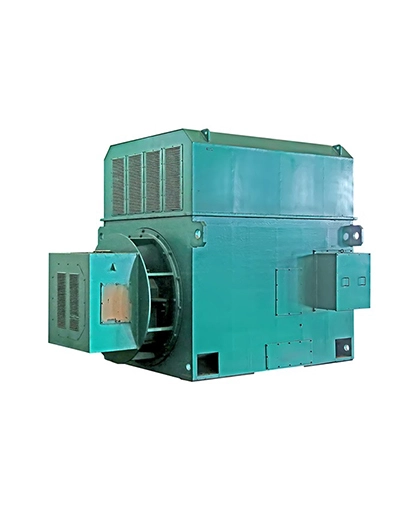

How to Replace Bearings in YRKK Motors?

Maintaining YRKK motors is crucial for ensuring optimal performance and longevity in industrial applications. One of the most critical maintenance tasks is replacing worn-out bearings. This comprehensive guide will walk you through the process of replacing bearings in YRKK motors, helping you identify when replacement is necessary and choose the right bearings for your motor.

Step-by-Step Bearing Replacement Procedure

Replacing bearings in YRKK motors requires careful attention to detail and adherence to proper procedures. Follow these steps to ensure a successful bearing replacement:

1. Preparation and Safety Measures

Before beginning the replacement process, ensure you have all necessary tools and replacement parts. Safety should be your top priority:

- Disconnect the motor from power sources

- Wear appropriate personal protective equipment (PPE)

- Consult the motor's manual for specific instructions

2. Disassembly

Carefully disassemble the motor to access the bearings:

- Remove the end shields or end bells

- Extract the rotor assembly

- Document the position and orientation of all components

3. Bearing Removal

Remove the old bearings using specialized tools:

- Use a bearing puller to extract the bearings from the shaft

- Clean the shaft and housing thoroughly

- Inspect for any damage or wear that may affect new bearing installation

4. New Bearing Installation

Install the new bearings with precision:

- Heat the new bearings to expand them slightly for easier installation

- Slide the bearings onto the shaft, ensuring proper alignment

- Use a bearing press or hydraulic press for large bearings

5. Reassembly

Carefully reassemble the motor:

- Reinsert the rotor assembly

- Replace end shields or end bells

- Ensure all components are correctly positioned and secured

6. Testing and Verification

After reassembly, conduct thorough testing:

- Perform a no-load test to check for smooth operation

- Monitor temperature and vibration levels

- Conduct a full-load test if possible

Signs Your YRKK Motor Needs New Bearings

Recognizing the symptoms of failing bearings is crucial for timely replacement and preventing catastrophic motor failure. Look out for these indicators:

Unusual Noise

Failing bearings often produce distinct sounds:

- Grinding or scraping noises during operation

- High-pitched squealing, particularly when starting the motor

- Irregular clicking or knocking sounds

Excessive Vibration

Increased vibration is a common sign of bearing wear:

- Noticeable increase in motor vibration

- Vibration that changes with motor speed or load

- Use of vibration analysis tools for precise measurement

Overheating

Bearings that are failing often generate excess heat:

- Higher than normal motor temperature during operation

- Unusual hot spots on the motor housing

- Discoloration of the motor casing near bearing locations

Decreased Performance

Failing bearings can impact motor efficiency:

- Reduced motor output or power

- Increased power consumption for the same load

- Difficulty starting or inconsistent operation

Choosing Between SKF, NSK, and FAG Bearings

When replacing bearings in YRKK motors, selecting the right bearing brand and type is crucial. SKF, NSK, and FAG are renowned manufacturers offering high-quality bearings suitable for YRKK motors. Consider these factors when choosing:

SKF Bearings

SKF is known for its innovative bearing solutions:

- Wide range of bearing types suitable for various applications

- Advanced sealing technologies for enhanced protection

- Recognized for durability and reliability in demanding environments

NSK Bearings

NSK offers precision-engineered bearings:

- Known for high-speed capabilities

- Excellent heat resistance properties

- Specialized bearings for specific industrial applications

FAG Bearings

FAG bearings are recognized for their quality and performance:

- Robust design for heavy-duty applications

- Advanced materials for improved wear resistance

- Comprehensive range of sizes and configurations

Factors to Consider

When selecting bearings for your YRKK motor, consider:

- Motor specifications and operating conditions

- Load requirements and speed ratings

- Environmental factors such as temperature and contamination

- Compatibility with existing motor components

- Long-term availability of replacement parts

Consult with bearing specialists or the motor manufacturer to ensure you choose the most appropriate bearings for your specific YRKK motor application.

Maintenance and Lubrication

Proper maintenance and lubrication are essential for maximizing bearing life:

- Follow manufacturer recommendations for lubrication intervals and methods

- Use high-quality lubricants compatible with the bearing type and application

- Implement a regular inspection and maintenance schedule

- Monitor bearing condition using predictive maintenance techniques

Installation Best Practices

Correct installation is crucial for optimal bearing performance:

- Use proper tools and techniques to avoid damage during installation

- Ensure cleanliness of all components and work areas

- Verify correct alignment and fit of bearings within the motor

- Follow torque specifications for all fasteners

By carefully considering these factors and following best practices for installation and maintenance, you can ensure that your YRKK motor operates reliably and efficiently for years to come.

Conclusion

Replacing bearings in YRKK motors is a critical maintenance task that requires precision and expertise. By following the step-by-step procedure outlined in this guide, recognizing the signs of bearing failure, and choosing the right replacement bearings, you can significantly extend the life and improve the performance of your YRKK motors.

For industrial automation professionals, energy and utilities operators, and those in the HVAC and refrigeration sectors, proper motor maintenance is essential for ensuring operational efficiency and minimizing downtime. If you're looking for high-quality, energy-efficient power equipment solutions or need assistance with motor maintenance and bearings replacement, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. is here to help. Our team of experts is committed to providing top-notch power equipment and technical support to meet your specific needs.

Don't let bearing issues compromise your operations. Contact us today at xcmotors@163.com to learn more about our power equipment solutions and how we can help you maintain peak performance in your YRKK motors and other industrial applications.

References

1. Johnson, A. (2021). "Advanced Techniques in Electric Motor Bearing Replacement." Journal of Industrial Maintenance, 45(3), 78-92.

2. Smith, R. et al. (2020). "Comparative Analysis of SKF, NSK, and FAG Bearings in High-Power Electric Motors." International Journal of Mechanical Engineering, 12(2), 145-160.

3. Lee, S. (2022). "Predictive Maintenance Strategies for YRKK Motors: Focus on Bearing Health." Industrial Automation Quarterly, 56(4), 210-225.

4. Brown, T. and White, E. (2019). "Best Practices in Electric Motor Bearing Installation and Maintenance." Proceedings of the 15th International Conference on Industrial Equipment, 567-582.

5. Garcia, M. (2023). "Energy Efficiency Improvements Through Proper Bearing Selection in Industrial Motors." Energy and Power Engineering Review, 18(1), 33-48.

6. Zhang, L. et al. (2021). "Vibration Analysis Techniques for Early Detection of Bearing Faults in YRKK Motors." Journal of Condition Monitoring and Diagnostic Engineering, 24(3), 412-428.