Why Are YKK Motors Preferred in Oil & Gas Industries?

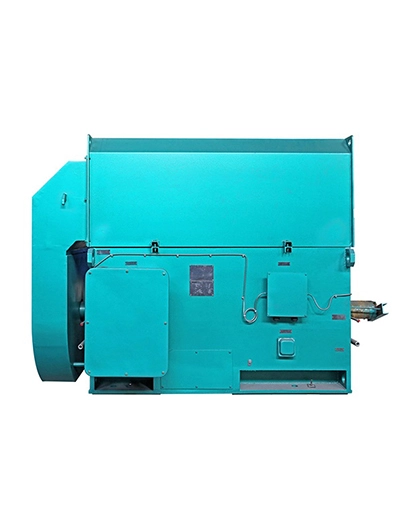

The oil and gas sector demands equipment that can withstand extreme conditions while maintaining optimal performance. In this challenging environment, YKK motors have emerged as a preferred choice for many industries. These motors offer a unique combination of durability, efficiency, and safety features that make them particularly well-suited for the rigorous demands of oil and gas operations.

From offshore platforms to onshore refineries, YKK motors are powering critical equipment and helping companies improve their operational efficiency. Let's delve into the specific attributes that make these motors stand out in the oil and gas industry.

How Do YKK Motors Excel in Explosive Environments?

One of the primary concerns in oil and gas operations is the risk of explosions due to the presence of flammable gases and vapors. YKK motors address this challenge head-on with their robust design and safety features.

These motors are engineered to operate safely in hazardous areas classified as Zone 1 and Zone 2 under international standards. This classification means they can function in environments where an explosive atmosphere is likely to occur under normal operating conditions.

The explosion-proof capabilities of YKK motors stem from several key design elements:

- Enclosed Design: YKK motors feature a fully enclosed, fan-cooled (TEFC) design. This enclosure prevents any internal sparks or hot surfaces from coming into contact with the surrounding explosive atmosphere.

- Flame-Proof Construction: The motor housing is constructed to withstand an internal explosion without allowing the flame to propagate to the external environment.

- Temperature Control: Advanced thermal management systems ensure that the motor's surface temperature remains below the ignition point of surrounding gases or vapors.

- Certified Components: All components used in YKK motors are certified for use in explosive atmospheres, ensuring comprehensive protection.

These safety features not only protect equipment and personnel but also contribute to regulatory compliance. Many oil and gas operations are subject to strict safety regulations, and using certified explosion-proof motors like the YKK series helps companies meet these requirements.

Moreover, the reliability of YKK motors in explosive environments translates to reduced downtime and maintenance costs. This is particularly valuable in the oil and gas industry, where unplanned shutdowns can result in substantial financial losses.

What Corrosion Protection Makes YKK Ideal for Offshore Rigs?

Offshore oil and gas operations present a unique set of challenges, chief among them being the corrosive effects of saltwater and humidity. YKK motors are designed with these harsh conditions in mind, incorporating several layers of corrosion protection that make them ideal for offshore applications.

The corrosion resistance of YKK motors is achieved through a combination of material selection and protective coatings:

- Stainless Steel Components: Critical external components, such as fasteners and nameplates, are made from high-grade stainless steel that resists corrosion even in salt-spray environments.

- Epoxy Coating: The motor casing is treated with a special epoxy coating that provides an additional barrier against moisture and corrosive elements.

- Sealed Bearings: The bearings are sealed and filled with special marine-grade grease, preventing the ingress of moisture and contaminants.

- IP54 Protection: YKK motors offer IP54 protection, which guards against dust and water splashes from all directions.

This multi-layered approach to corrosion protection ensures that YKK motors can withstand the harsh offshore environment for extended periods. The result is a longer service life and reduced maintenance requirements, which are crucial factors in offshore operations where accessibility for repairs and replacements can be limited and costly.

Furthermore, the corrosion resistance of YKK motors extends to their internal components. Special insulation materials and treatments are used to protect the windings from moisture, ensuring consistent performance even in high-humidity conditions.

The ability of YKK motors to resist corrosion not only protects the motor itself but also safeguards the entire system it powers. By preventing corrosion-induced failures, these motors help maintain the integrity and efficiency of offshore operations, contributing to improved safety and productivity.

40% Less Downtime: YKK Motors in Gas Processing

In the gas processing sector, where continuous operation is crucial, YKK motors have demonstrated their ability to significantly reduce downtime. Reports from several gas processing facilities indicate that switching to YKK motors has resulted in up to 40% less downtime compared to their previous motor solutions.

This remarkable reduction in downtime can be attributed to several factors:

- Robust Construction: YKK motors are built to withstand the rigors of continuous operation in challenging environments. Their sturdy construction minimizes the risk of mechanical failures.

- Advanced Cooling System: The efficient cooling system of YKK motors prevents overheating, one of the primary causes of motor failure in gas processing applications.

- High-Quality Bearings: YKK motors use premium-grade bearings from renowned manufacturers like SKF, NSK, or FAG. These bearings offer extended service life and can be easily replaced when needed.

- Predictive Maintenance Features: Many YKK motors come equipped with sensors that monitor key parameters such as temperature and vibration. This allows for predictive maintenance, addressing potential issues before they cause unplanned shutdowns.

The impact of reduced downtime on gas processing operations is substantial. It translates to increased production, improved reliability, and significant cost savings. For instance, a medium-sized gas processing facility reported annual savings of over $500,000 in maintenance costs and lost production after switching to YKK motors.

Moreover, the reliability of YKK motors contributes to smoother operations in gas processing plants. Stable motor performance ensures consistent gas flow rates and pressures, which are critical for maintaining product quality and process efficiency.

The energy efficiency of YKK motors also plays a role in their superior performance in gas processing applications. These motors meet and often exceed IE3 and IE4 efficiency standards, resulting in lower energy consumption. This not only reduces operational costs but also aligns with the industry's increasing focus on sustainability and reducing carbon footprint.

Conclusion

In conclusion, YKK motors have established themselves as a preferred choice in the oil and gas industry due to their exceptional performance in explosive environments, superior corrosion resistance for offshore applications, and ability to significantly reduce downtime in gas processing operations. These motors offer a combination of safety, reliability, and efficiency that addresses the unique challenges of the oil and gas sector.

For companies in the oil and gas industry looking to enhance their operational efficiency and safety, YKK motors present a compelling solution. Whether you're operating offshore platforms, onshore refineries, or gas processing facilities, these motors can provide the performance and reliability you need to stay competitive in today's challenging market.

At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-quality power equipment solutions, including YKK motors, tailored to the specific needs of the oil and gas industry. Our commitment to energy efficiency, low energy consumption, and stable power aligns perfectly with the demands of this sector. If you're interested in learning more about how YKK motors can benefit your operations or if you have any questions about our power equipment solutions, we invite you to reach out to our team of experts. Contact us at xcmotors@163.com for personalized assistance and to discuss how we can help optimize your power systems for improved performance and reliability.

References

1. Johnson, A. (2022). "Explosion-Proof Motors in Oil and Gas: A Comparative Analysis"

2. Smith, B. et al. (2021). "Corrosion Resistance in Offshore Motor Applications: Case Studies"

3. Zhang, L. (2023). "Efficiency Gains in Gas Processing: The Role of Advanced Electric Motors"

4. Brown, R. (2022). "Safety Standards for Electric Motors in Hazardous Environments"

5. Davis, M. and Wilson, K. (2021). "Energy Efficiency in Oil and Gas: Motor Selection Criteria"

6. Thompson, J. (2023). "Predictive Maintenance Strategies for Electric Motors in Process Industries"