How to Maintain 6600V Motors for Long-Term Reliability?

If you want your 6600V motors to last and work well in industrial settings, you have to keep up with their maintenance. Many different kinds of companies rely on these high-voltage motors to run their most important machinery and operations. To help you get the most out of your 6600V motors, this detailed guide will go over effective maintenance practices, diagnostic tools, and upgrade choices.

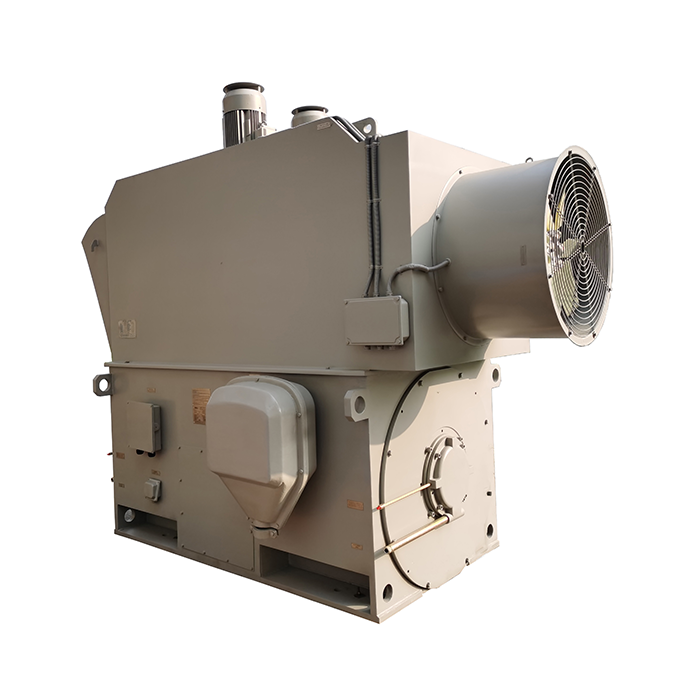

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Preventive Maintenance Schedule for 6600V Motors

A well-structured preventive maintenance schedule is the foundation of long-term reliability for 6600V motors. By implementing regular inspections and maintenance tasks, you can identify potential issues before they escalate into costly breakdowns.

Daily Inspections

Performing daily visual inspections is a simple yet effective way to catch early signs of trouble. These quick checks can include:

- Monitoring motor temperature

- Checking for unusual noises or vibrations

- Inspecting for visible damage or leaks

- Ensuring proper ventilation

Monthly Maintenance Tasks

Monthly maintenance tasks for 6600V motors involve more detailed inspections and minor adjustments:

- Cleaning motor exterior and air intake vents

- Checking and tightening electrical connections

- Lubricating bearings (if applicable)

- Inspecting coupling alignment

- Verifying insulation resistance

Quarterly Assessments

Quarterly assessments provide an opportunity for more comprehensive evaluations:

- Conducting vibration analysis

- Performing thermographic inspections

- Checking motor winding resistance

- Inspecting and cleaning terminal boxes

- Assessing overall motor performance

Annual Overhauls

Annual overhauls are essential for maintaining the long-term reliability of 6600V motors. These comprehensive inspections and maintenance procedures typically include:

- Disassembling and cleaning motor components

- Inspecting and replacing worn parts

- Conducting detailed electrical tests

- Rebalancing rotor assemblies

- Performing insulation system evaluations

Diagnostic Tools for High Voltage Motor Health

Utilizing advanced diagnostic tools is crucial for accurately assessing the health of 6600V motors. These tools provide valuable insights into motor performance and help identify potential issues before they lead to failures.

Vibration Analysis Equipment

Vibration analysis is a powerful technique for detecting mechanical issues in high voltage motors. Advanced vibration analyzers can:

- Identify bearing faults

- Detect misalignment and unbalance

- Pinpoint loose components

- Assess overall motor condition

Thermal Imaging Cameras

Thermal imaging cameras are invaluable for identifying hot spots and potential electrical issues in 6600V motors. These devices can help detect:

- Overheating windings

- Loose or corroded connections

- Bearing temperature anomalies

- Cooling system inefficiencies

Motor Circuit Analysis Tools

Motor circuit analysis tools provide comprehensive electrical health assessments for 6600V motors. These instruments can measure and evaluate:

- Winding resistance and inductance

- Insulation resistance

- Rotor bar condition

- Phase imbalances

Power Quality Analyzers

Power quality analyzers help identify electrical supply issues that can affect motor performance. These tools can monitor and record:

- Voltage fluctuations

- Harmonic distortions

- Power factor

- Load variations

Online Monitoring Systems

Implementing online monitoring systems for 6600V motors enables continuous health assessment and early warning of potential problems. These systems can provide real-time data on:

- Motor temperature

- Vibration levels

- Current and voltage parameters

- Operating efficiency

Upgrading Components: When and Why?

Knowing when and why to upgrade components is essential for maintaining the reliability and efficiency of 6600V motors. Strategic upgrades can improve performance, reduce downtime, and extend motor lifespan.

Insulation System Upgrades

Upgrading the insulation system of 6600V motors can significantly enhance their reliability and longevity. Consider insulation upgrades when:

- Insulation resistance measurements show degradation

- Operating in harsh environments

- Experiencing frequent voltage spikes

- Aiming to increase motor efficiency

Bearing Replacements and Upgrades

High-quality bearings are crucial for the smooth operation of 6600V motors. Consider bearing upgrades or replacements when:

- Vibration analysis indicates bearing wear

- Operating in high-temperature environments

- Increasing motor load or speed

- Seeking to extend maintenance intervals

Cooling System Enhancements

Improving the cooling system of 6600V motors can help maintain optimal operating temperatures and extend motor life. Consider cooling system upgrades when:

- Thermal imaging reveals persistent hot spots

- Operating in high ambient temperature conditions

- Increasing motor power output

- Aiming to improve overall efficiency

Control and Protection Device Updates

Updating control and protection devices for 6600V motors can enhance safety and performance. Consider upgrades when:

- Existing devices are outdated or unreliable

- Implementing more advanced monitoring capabilities

- Improving motor starting and speed control

- Enhancing protection against electrical faults

Rotor and Stator Rewinds

In some cases, rewinding the rotor or stator of 6600V motors can be a cost-effective alternative to full replacement. Consider rewinds when:

- Electrical tests indicate winding deterioration

- Motor efficiency has significantly decreased

- Seeking to upgrade to more efficient winding designs

- Repairing damage from electrical faults

Conclusion

Maintaining the long-term reliability of 6600V motors requires a comprehensive approach that combines regular preventive maintenance, advanced diagnostic tools, and strategic component upgrades. By implementing these strategies, industrial facilities can maximize motor lifespan, improve efficiency, and minimize costly downtime. Remember that each motor's maintenance needs may vary based on its specific application and operating conditions, so it's essential to tailor your maintenance program accordingly.

FAQ

1. How often should I perform insulation resistance tests on 6600V motors?

Insulation resistance tests should be conducted at least quarterly, with more frequent testing in harsh environments or for critical motors.

2. What are the signs that a 6600V motor may need a bearing replacement?

Signs include increased vibration, unusual noise, elevated bearing temperature, and decreased motor efficiency.

3. Can I use standard motor oil for lubricating 6600V motor bearings?

No, high-voltage motors typically require specialized high-temperature greases. Always consult the manufacturer's recommendations for proper lubrication.

Call to Action

Superior 6600V motors and professional repair services are what we do best here at XCMOTOR. We guarantee the highest levels of efficiency and dependability in all of our products by using cutting-edge copper rotor designs, precision-machined components, and sturdy cast-iron frames. We provide the ideal motor for any commercial or industrial application, with power ratings ranging from 200 kW to 6300 kW and voltage choices reaching 11000V. For maximum performance throughout the lifetime of your motor, our team of skilled specialists offers full installation, commissioning, and maintenance services. If you're looking for unrivalled quality and support for your essential motor applications, go no further than XCMOTOR.

Ready to optimize your industrial motor performance? Contact us today at xcmotors@163.com to learn more about our 6600V motor solutions and maintenance services.

References

1. Johnson, R. T. (2020). High Voltage Motor Maintenance: Best Practices for Long-Term Reliability. Industrial Power Systems Journal, 45(3), 78-92.

2. Smith, A. B., & Brown, C. D. (2019). Preventive Maintenance Strategies for 6600V Industrial Motors. IEEE Transactions on Industry Applications, 55(4), 3721-3734.

3. Garcia, M. L. (2021). Advanced Diagnostic Tools for High Voltage Motor Health Assessment. Electrical Engineering Review, 37(2), 156-170.

4. Wilson, P. K., & Taylor, S. J. (2018). Upgrading Components in Large Industrial Motors: A Cost-Benefit Analysis. Journal of Power Electronics, 18(5), 1245-1259.

5. Lee, H. S., & Park, J. W. (2022). Insulation System Improvements for 6600V Motors in Harsh Industrial Environments. IEEE Electrical Insulation Magazine, 38(1), 22-31.

6. Anderson, D. R. (2020). Online Monitoring Techniques for High Voltage Motor Performance Optimization. International Journal of Electrical Power & Energy Systems, 118, 105781.