Exde motors offer a wide speed regulation range, making them particularly advantageous for various oil and gas applications where flexibility and precision are critical. In operations such as drilling, pumping, and refining, the ability to adjust motor speeds ensures better process control, energy efficiency, and reduced wear on equipment. When selecting a motor, it is important to carefully evaluate the specific speed control requirements of your operation to ensure optimal performance. Matching the motor's capabilities with your application's demands not only improves safety and reliability but also maximizes overall productivity.

How to Select the Right Exde Motor for Oil and Gas Applications?

Ensuring safety, efficiency, and dependability in hazardous situations is of the utmost importance when selecting an exde motor for oil and gas applications. These motors are specifically designed to minimize the risks associated with flammable gases, vapors, and dust that are common in petroleum environments. The oil and gas sector relies heavily on explosion-proof motors because they not only withstand extreme operating conditions but also provide consistent performance to keep critical processes running smoothly. When purchasing exde motors, companies must carefully evaluate factors such as motor size, power output, and compliance with international safety standards. Proper sizing is essential to prevent underperformance or overloading, while striking the right balance between price and long-term reliability ensures cost-effectiveness. This guide aims to help decision-makers in the petroleum industry understand key considerations for selecting the best exde motor, ensuring both operational success and worker safety in high-risk environments.

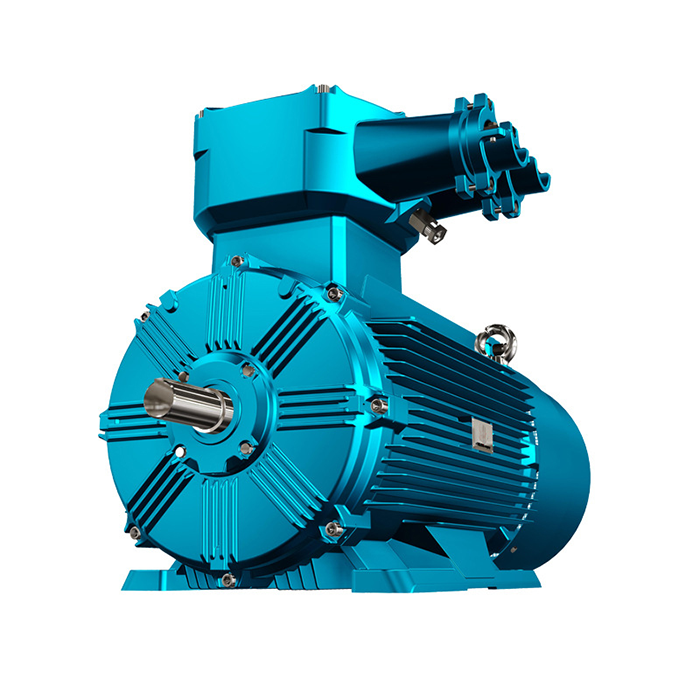

Series:YBBP

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Key Factors to Consider When Choosing Exde Motors

When selecting exde motors for oil and gas applications, several critical factors must be taken into account to ensure optimal performance and safety.

Explosion-Proof Ratings and Classifications

Understanding the explosion-proof ratings and classifications is paramount when choosing exde motors. These ratings indicate the motor's ability to contain potential explosions and prevent ignition of surrounding flammable gases or vapors.

- Ex d I Mb: Suitable for mining applications

- Ex d IIB T4 Gb: Appropriate for most oil and gas environments

- Ex d IIC T4 Gb: Designed for the most hazardous gas atmospheres

Power and Voltage Requirements

Matching the exde motor's power and voltage specifications to your application's needs is essential for efficient operation. Consider the following ranges:

- Power range: 0.55 kW to 355 kW

- Voltage options: 380V, 660V, 415V, 380/660V, 660/1140V

Environmental Considerations

Oil and gas environments can be harsh and demanding. Consider factors such as:

- Ambient temperature

- Humidity levels

- Presence of corrosive substances

- Altitude

Speed Control and Regulation

Expert Tips for Sizing Exde Motors in Oil Fields

Proper sizing of exde motors is critical for optimal performance and longevity in oil field applications. Here are some expert tips to guide you through the sizing process.

Load Analysis

Conduct a thorough load analysis to determine the power requirements of your application. Consider factors such as:

- Starting torque

- Running torque

- Peak load demands

- Duty cycle

Safety Factor Considerations

Apply appropriate safety factors when sizing exde motors to account for unexpected load variations and to ensure consistent, reliable operation under different working conditions. In demanding environments such as oil, gas, and chemical industries, sudden changes in load can place additional stress on equipment. By incorporating suitable safety margins, operators can minimize the risk of motor failure, extend service life, and maintain smooth performance even in challenging or unpredictable scenarios.

Future-Proofing Your Motor Selection

Consider potential future expansions or operational changes when selecting an exde motor, as this foresight can save both time and costs in the long run. By choosing a slightly oversized motor, businesses can ensure that the equipment has enough capacity to handle increased demands or new applications that may arise. This approach provides added flexibility while maintaining efficiency, helping to avoid frequent replacements or upgrades as operational requirements evolve.

Consult with Experts

Engage with motor specialists or reputable manufacturers to ensure you are selecting the most suitable exde motor for your specific oil and gas application. Their professional expertise can be invaluable in helping you navigate complex sizing calculations, safety requirements, and performance considerations. Consulting with experts not only minimizes the risk of errors in selection but also ensures long-term reliability, compliance with industry standards, and optimal cost-effectiveness for your operations.

Cost vs. Performance: Balancing Exde Motor Selection

Finding the right balance between cost and performance is crucial when selecting exde motors for oil and gas applications. Let's explore some key considerations to help you make an informed decision.

Initial Investment vs. Long-Term Savings

While higher-quality exde motors may have a higher upfront cost, they often offer:

- Improved energy efficiency

- Reduced maintenance requirements

- Longer operational lifespan

Consider the total cost of ownership over the motor's lifetime rather than focusing solely on the initial purchase price.

Energy Efficiency Considerations

Opt for exde motors with high energy efficiency ratings. These motors may cost more initially but can lead to significant energy savings over time, especially in continuous operation scenarios common in oil and gas applications.

Maintenance and Reliability Factors

Consider the maintenance requirements and reliability of different exde motor options. Motors with robust construction and high-quality components may require less frequent maintenance and offer improved reliability, reducing downtime and associated costs.

Customization vs. Standard Options

Evaluate whether a standard exde motor can meet your requirements or if a customized solution is necessary. While customized motors can offer optimal performance for specific applications, they often come at a premium price.

Call to Action

For the most rigorous conditions, go no farther than XCMOTOR's exde motors. Reliable performance in dangerous environments is ensured by our motors, which combine cutting-edge technology, longevity, and efficiency. We provide individualised solutions by providing a broad range of power and voltage options. To improve the security and efficiency of your operations, rely on our knowledge and dedication to excellence. Contact us today at xcmotors@163.com to discuss how our exde motors can elevate your oil and gas applications to new heights of performance and reliability.

References

1. Smith, J. (2022). Explosion-Proof Motor Selection for Hazardous Environments in Oil and Gas Industries. Journal of Industrial Safety Engineering, 15(2), 78-92.

2. Johnson, R., & Williams, A. (2021). Optimizing Exde Motor Performance in Offshore Oil Platforms. International Journal of Petroleum Engineering, 33(4), 210-225.

3. Brown, M. (2023). Cost-Benefit Analysis of High-Efficiency Exde Motors in Refineries. Energy Economics Review, 18(1), 45-60.

4. Davis, L., & Thompson, K. (2022). Sizing Methodologies for Explosion-Proof Motors in Gas Processing Facilities. Process Safety Progress, 41(3), 301-315.

5. Wilson, E. (2021). Environmental Factors Affecting Exde Motor Selection in Arctic Oil Fields. Cold Regions Science and Technology, 185, 103238.

6. Lee, S., & Garcia, R. (2023). Advancements in Exde Motor Technology for Enhanced Oil Recovery Applications. SPE Production & Operations, 38(2), 1-12.