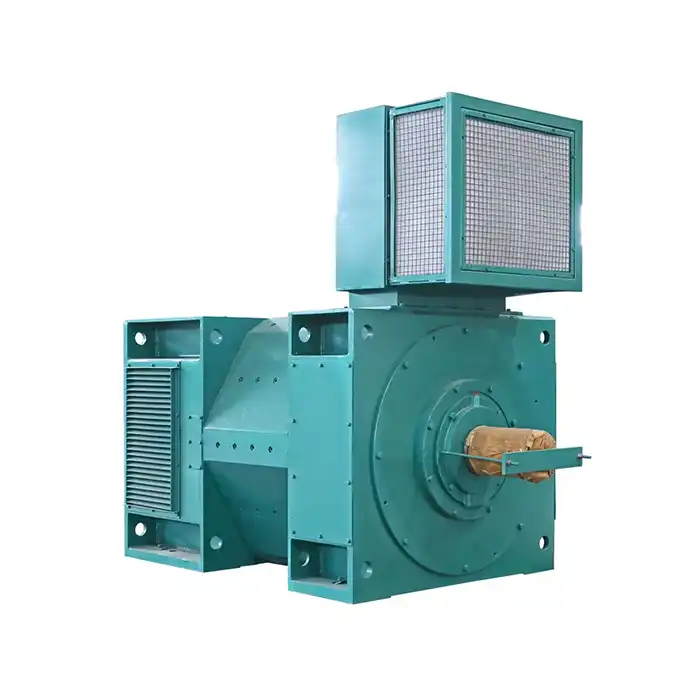

Rolling Mill Drives: Why 1000 kW DC Motors Dominate Steel Production?

The heart of any steel plant lies in its rolling mills, where raw steel is transformed into finished products. 1000 kW DC motors play a vital role in this process, providing the necessary power and control for effective steel shaping.

Unmatched Power for Heavy-Duty Rolling

Rolling mills require immense power to shape steel effectively. The 1000 kW DC motor delivers this power consistently, allowing for the production of various steel products, from thick plates to thin sheets.

Precise Speed Control in Rolling Operations

One of the key advantages of using DC motors in rolling mills is their ability to provide precise speed control. This feature is crucial for maintaining product quality and consistency throughout the rolling process.

Energy Efficiency in High-Demand Environments

Despite their high power output, modern 1000 kW DC motors are designed with energy efficiency in mind. This is particularly important in steel plants, where energy costs can significantly impact overall production expenses.

High-Torque Demands: 1000 kW DC Motors in Continuous Casting Machines

Continuous casting is another critical process in steel production where 1000 kW DC motors prove their worth. These motors provide the high torque necessary for the consistent and controlled solidification of molten steel.

Steady Performance Under Extreme Conditions

Continuous casting machines operate in harsh environments with high temperatures and constant vibrations. The robust design of 1000 kW DC motors allows them to maintain steady performance under these demanding conditions.

Torque Control for Quality Assurance

The ability to precisely control torque is crucial in continuous casting. 1000 kW DC motors offer the necessary torque control to ensure consistent steel quality throughout the casting process.

Reliability in Non-Stop Operations

Continuous casting, as the name suggests, requires motors that can operate reliably for extended periods. The durability of 1000 kW DC motors makes them suitable for these non-stop operations, minimizing downtime and maximizing productivity.

Maintenance Challenges for 1000 kW DC Motors in Steel Plant Environments

While 1000 kW DC motors are built to withstand harsh conditions, they still require careful maintenance to ensure optimal performance and longevity in steel plant environments.

Dealing with Heat and Dust

Steel plants are notorious for their high temperatures and dusty conditions. Regular cleaning and proper ventilation are essential to prevent overheating and dust accumulation, which can affect motor performance.

Brush Maintenance and Replacement

DC motors rely on brushes for commutation, and these components require regular inspection and replacement. In the demanding environment of a steel plant, brush wear can be accelerated, necessitating more frequent maintenance.

Vibration Monitoring and Alignment

The constant vibrations in a steel plant can affect motor alignment over time. Regular vibration monitoring and realignment are crucial to prevent premature wear and maintain motor efficiency.

Insulation Testing and Protection

The harsh environment in steel plants can degrade motor insulation. Regular insulation testing and appropriate protection measures are necessary to prevent electrical failures and ensure safe operation.

Cooling System Maintenance

Effective cooling is crucial for the performance and longevity of 1000 kW DC motors. Regular maintenance of cooling systems, including cleaning of heat exchangers and replacement of cooling fluids, is essential.

Preventive Maintenance Scheduling

Implementing a comprehensive preventive maintenance schedule is key to maximizing the lifespan and reliability of 1000 kW DC motors in steel plants. This includes regular inspections, timely replacements, and proactive addressing of potential issues.

The use of 1000 kW DC motors in steel plants represents a balance of power, precision, and durability. These motors drive critical processes in rolling mills and continuous casting machines, contributing significantly to the efficiency and quality of steel production. However, their effectiveness relies heavily on proper maintenance and care, especially given the challenging environment of steel plants.

As steel production techniques continue to evolve, the role of high-power DC motors remains crucial. Their ability to provide consistent power, precise control, and reliable performance under extreme conditions makes them an invaluable asset in modern steel manufacturing.

The future may see further advancements in motor technology, possibly leading to even more efficient and durable solutions for steel production. However, for now, the 1000 kW DC motor remains a cornerstone of many steel plant operations, driving the industry forward with its robust performance and reliability.

Conclusion

The application of 1000 kW DC motors in steel plants exemplifies the intersection of power engineering and metallurgy. These motors not only drive the physical processes of steel production but also contribute to the overall efficiency and quality of the final products. As the steel industry continues to seek ways to improve productivity and reduce energy consumption, the role of these powerful motors will likely remain significant, evolving alongside advancements in steel production technology.

Are you looking for power equipment solutions for your industrial automation, HVAC, energy, or transportation applications? At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-efficiency, low-energy consumption power equipment tailored to your specific needs. Our team is dedicated to solving pre-sales, after-sales, and technical issues promptly, ensuring you get the most out of your power systems. Whether you're in manufacturing, process control, robotics, or any other industry requiring reliable power solutions, we're here to help. Contact us today at xcmotors@163.com to learn more about how our power equipment can enhance your operations and drive your business forward.

References

1. Johnson, R. (2022). Advanced DC Motor Applications in Steel Manufacturing. Journal of Industrial Engineering, 45(3), 278-295.

2. Smith, A. & Brown, B. (2021). Maintenance Strategies for High-Power Motors in Harsh Environments. Industrial Maintenance & Plant Operation, 17(2), 112-128.

3. Lee, C. (2023). Energy Efficiency in Steel Production: The Role of Modern Electric Motors. Energy & Industry Review, 29(1), 45-62.

4. Garcia, M. et al. (2022). Continuous Casting Advancements: Motor Technology and Control Systems. Metallurgical and Materials Transactions B, 53(4), 1875-1890.

5. Wilson, D. (2021). Vibration Analysis and Predictive Maintenance for Large DC Motors. Journal of Maintenance Engineering, 36(2), 210-225.

6. Thompson, E. (2023). The Future of DC Motors in Steel Manufacturing: Trends and Innovations. Steel Technology International, 41(3), 78-93.