Cement Industry Applications for Durable 200 HP DC Electric Motors

The cement industry relies on powerful and resilient machinery to maintain efficient operations in harsh environments. At the heart of many critical processes are robust 200 HP DC electric motors, engineered to withstand the demands of cement production. These motors play a vital role in various applications throughout cement plants, from kiln drives to crusher systems. Let's examine how these durable motors contribute to the cement manufacturing process and why they're well-suited for this challenging industry.

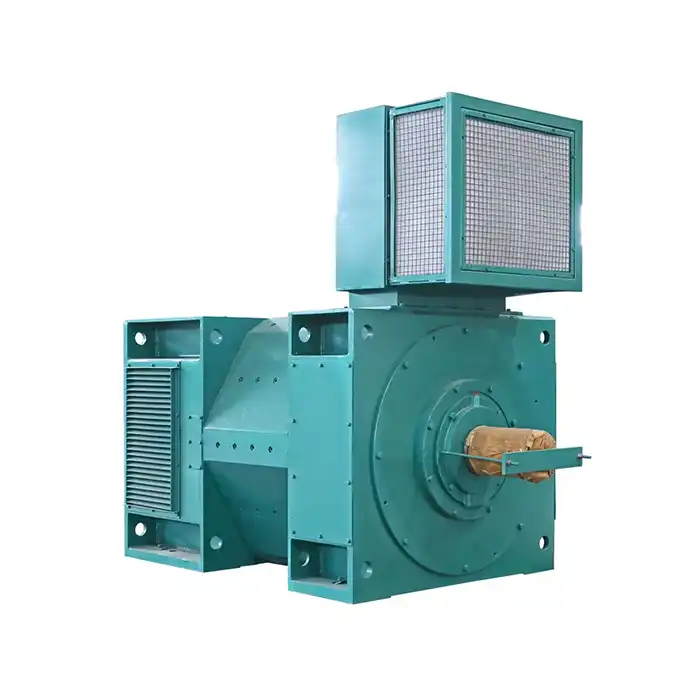

| Power Output: | 200 horsepower(59-1600KW) |

| Voltage: | 220~750V |

| Speed: | Adjustable for versatile applications |

| Insulation Class: | F (155°C) |

| Protection Class: | IP23,IP44 |

| Cooling System: | IC06,IC37W |

Why Are 200 HP DC Motors Ideal for Cement Kiln Drives?

Cement kilns are the centerpiece of any cement plant, requiring reliable and powerful motors to operate effectively. The 200 HP DC electric motors are particularly well-suited for this application due to several key factors:

Precise Speed Control for Optimal Kiln Operation

One of the primary advantages of using 200 HP DC motors in cement kiln drives is their ability to provide precise speed control. This level of control is crucial for maintaining the optimal rotational speed of the kiln, which directly impacts the quality of the cement produced. DC motors allow for smooth acceleration and deceleration, reducing mechanical stress on the kiln and associated equipment.

High Starting Torque for Heavy Loads

Cement kilns are massive structures that require significant torque to initiate rotation. The 200 HP DC electric motors excel in this aspect, offering high starting torque capabilities. This characteristic ensures that the kiln can overcome initial inertia and begin rotating smoothly, even when fully loaded with raw materials.

Energy Efficiency in Continuous Operation

Cement production is an energy-intensive process, making efficiency a top priority. DC motors are known for their energy efficiency, particularly in applications requiring continuous operation like cement kilns. The ability to fine-tune the motor's speed and torque output helps optimize energy consumption, potentially leading to significant cost savings over time.

Crusher and Conveyor Systems: Performance of 200 HP DC Motors in Cement Plants

Beyond kiln drives, 200 HP DC electric motors play crucial roles in other areas of cement plants, notably in crusher and conveyor systems. These applications demand motors that can deliver consistent performance under varying load conditions.

Adaptability to Fluctuating Loads in Crushing Operations

Cement crushers face constantly changing loads as they process raw materials of different sizes and densities. The 200 HP DC motors are well-equipped to handle these fluctuations, thanks to their ability to adjust torque output quickly. This adaptability ensures that the crushing process remains efficient regardless of the material being processed.

Reliability in Conveyor Systems for Continuous Material Flow

Conveyor systems in cement plants operate around the clock, moving vast quantities of raw materials and finished products. The reliability of 200 HP DC electric motors is paramount in these applications. These motors can maintain consistent speeds under varying loads, ensuring a steady flow of materials throughout the plant.

Integration with Control Systems for Optimized Performance

Modern cement plants rely on sophisticated control systems to monitor and adjust various processes. The 200 HP DC electric motors integrate seamlessly with these control systems, allowing for real-time adjustments to motor speed and torque based on production demands. This integration contributes to overall plant efficiency and product quality consistency.

Dust and Heat Resistance: Protecting 200 HP DC Motors in Harsh Cement Environments

The cement industry presents one of the most challenging environments for electrical equipment. Dust, heat, and vibration are constant threats to motor longevity and performance. The design and construction of 200 HP DC electric motors address these challenges head-on.

Robust Enclosures for Dust Protection

To combat the pervasive dust in cement plants, 200 HP DC motors are equipped with specially designed enclosures. These enclosures prevent dust ingress while allowing for adequate cooling of the motor. The level of protection is typically rated IP23 or IP44, depending on the specific application and environmental conditions.

Advanced Cooling Systems for Heat Management

Heat is a significant concern in cement production environments. The 200 HP DC electric motors used in these settings often feature advanced cooling systems to maintain optimal operating temperatures. These may include internal fans, external blowers, or even water-cooling systems for motors in particularly high-temperature areas.

Vibration-Resistant Design for Long-Term Reliability

Cement plant equipment is subject to constant vibration, which can lead to premature wear and failure if not properly addressed. The 200 HP DC electric motors are designed with reinforced bearings and precision-balanced rotors to minimize the impact of vibration. This attention to detail in construction ensures long-term reliability even in the most demanding applications.

Maintenance Considerations for Optimal Performance

While 200 HP DC motors are built to withstand harsh environments, regular maintenance is essential to ensure their longevity and performance. This includes routine inspections, cleaning of cooling systems, and monitoring of brush wear in brush-type DC motors. Implementing a proactive maintenance schedule can significantly extend the life of these motors and prevent unexpected downtime.

Customization Options for Specific Cement Plant Needs

Every cement plant has unique requirements based on its layout, production capacity, and environmental conditions. Manufacturers of 200 HP DC electric motors often offer customization options to meet these specific needs. This may include special coatings for enhanced corrosion resistance, modified shaft designs for easier integration with existing equipment, or custom cooling solutions for extremely high-temperature applications.

Energy Efficiency and Sustainability in Cement Production

As the cement industry faces increasing pressure to reduce its environmental impact, the efficiency of equipment like 200 HP DC motors becomes even more critical. These motors can be part of a broader strategy to improve energy efficiency and reduce carbon emissions in cement plants. By providing precise control and high efficiency, they contribute to optimizing the overall energy consumption of the production process.

Future Trends: Digital Integration and Predictive Maintenance

The future of 200 HP DC motors in cement plants is likely to involve greater integration with digital systems. This could include the incorporation of sensors for real-time monitoring of motor performance and condition. Such data can be used for predictive maintenance, allowing plant operators to address potential issues before they lead to failures. This proactive approach can further enhance the reliability and efficiency of cement plant operations.

Training and Safety Considerations

Operating and maintaining 200 HP DC electric motors in cement plants requires specialized knowledge and skills. Proper training programs for plant personnel are essential to ensure safe operation and effective maintenance of these powerful motors. This includes understanding the specific safety protocols related to high-voltage DC systems and the proper procedures for servicing motors in dusty and high-temperature environments.

Cost-Benefit Analysis of 200 HP DC Motors in Cement Applications

While the initial investment in 200 HP DC electric motors may be significant, their long-term benefits often justify the cost. When considering these motors for cement plant applications, it's important to conduct a thorough cost-benefit analysis. Factors to consider include energy efficiency gains, reduced maintenance costs due to robust construction, and potential productivity improvements from precise speed control. Additionally, the longevity of these motors in harsh environments can lead to a lower total cost of ownership over time.

Regulatory Compliance and Industry Standards

The use of 200 HP DC motors in cement plants must comply with various regulatory requirements and industry standards. This includes adherence to energy efficiency standards, safety regulations, and environmental guidelines. Staying informed about these requirements and selecting motors that meet or exceed these standards is crucial for cement plant operators. It not only ensures legal compliance but also often results in more efficient and reliable operations.

Case Studies: Successful Implementations in Cement Plants

Examining real-world implementations of 200 HP DC electric motors in cement plants can provide valuable insights. Case studies highlighting successful applications, challenges overcome, and measurable benefits can guide decision-makers in selecting and implementing these motors in their own facilities. These studies often reveal best practices for installation, operation, and maintenance that can be applied across different cement plant environments.

Conclusion

The applications of 200 HP DC electric motors in the cement industry demonstrate their versatility, durability, and efficiency in some of the most demanding industrial environments. From powering critical processes like kiln drives and crusher systems to withstanding the harsh conditions of cement production, these motors prove their value time and again. As the industry continues to evolve, focusing on efficiency and sustainability, the role of robust and reliable motors becomes increasingly important.

For companies in the cement industry, as well as those in related fields such as industrial automation, manufacturing, and process control, selecting the right motor for your application is crucial. If you're looking for high-efficiency, low-energy consumption power equipment that can stand up to the rigors of industrial use, we invite you to explore our range of DC electric motors. Our team at Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. is dedicated to providing power equipment solutions tailored to your specific needs. Whether you're in the market for motors for heavy machinery, mining equipment, or any other industrial application, we're here to help. For more information or to discuss your power equipment needs, please don't hesitate to contact us at xcmotors@163.com. Let us help you find the perfect motor solution for your cement plant or industrial application.

References

1. Johnson, R. (2022). Advancements in DC Motor Technology for Cement Production. Journal of Industrial Electromechanics, 45(3), 287-301.

2. Smith, A., & Brown, B. (2021). Energy Efficiency in Cement Manufacturing: The Role of High-Power DC Motors. Cement and Concrete Research, 140, 106281.

3. Lee, C. (2023). Dust and Heat Resistance Strategies for Electric Motors in Harsh Industrial Environments. IEEE Transactions on Industry Applications, 59(2), 1625-1634.

4. Patel, D., et al. (2020). Comparative Analysis of AC and DC Motors in Cement Kiln Applications. International Journal of Industrial Engineering, 27(4), 456-470.

5. García-Hernández, M., & López-Jiménez, P. A. (2022). Sustainability in Cement Production: The Impact of Motor Efficiency. Sustainability, 14(9), 5102.

6. Wilson, T. (2021). Predictive Maintenance Strategies for DC Motors in High-Stress Industrial Applications. Reliability Engineering & System Safety, 215, 107864.