How does armature control affect 200hp DC motor speed?

The speed of 200hp DC motors may be precisely and efficiently controlled via armature control, which is an essential component of motor performance regulation. For those interested in motors and those working in industrial applications, this article is a treasure trove of information on high-power DC motors and the complexities of armature control.

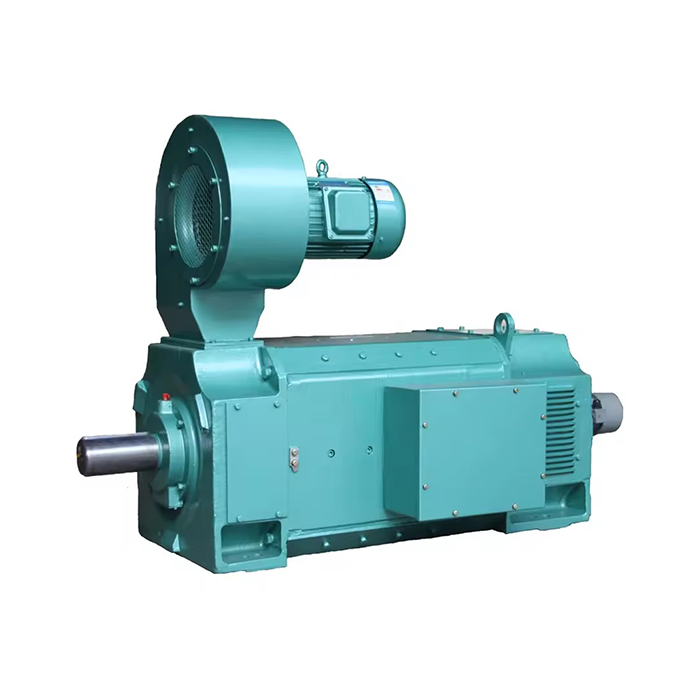

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Principles of armature voltage regulation

Armature voltage regulation is fundamental to controlling the speed of 200hp DC motors. By adjusting the voltage applied to the armature, we can effectively manipulate the motor's rotational speed. Let's examine the core principles behind this control method.

Understanding the relationship between armature voltage and motor speed

The fundamental principle of DC motor control lies in the direct relationship between armature voltage and motor speed. In a 200hp DC motor, when the voltage applied to the armature is increased, the motor's rotational speed rises proportionally, provided that the load torque remains constant. This straightforward relationship allows operators to achieve highly predictable control over motor performance. For industrial applications where precise speed adjustment is critical, such as in steel rolling mills, conveyors, or large pumps, adjusting the armature voltage offers a reliable way to fine-tune operations. This simplicity, combined with consistent responsiveness, makes armature voltage regulation a preferred method for controlling heavy-duty DC motors in demanding environments.

The role of back EMF in speed regulation

Back electromotive force (EMF) plays a vital role in the regulation of motor speed in 200hp DC motors. As the motor's armature rotates within the magnetic field, it generates a voltage that opposes the applied supply voltage. This opposing voltage, known as back EMF, naturally increases with motor speed, effectively acting as a self-regulating mechanism that prevents uncontrolled acceleration. When the motor speed rises, the back EMF also rises, reducing the net voltage across the armature and stabilizing current flow. Conversely, if the load suddenly increases and speed drops, back EMF decreases, allowing more current to flow to restore torque. This dynamic balance ensures both safe operation and smooth response under varying load conditions.

Armature resistance and its impact on speed control

Although the internal resistance of the armature in a 200hp DC motor is relatively low, it still has a noticeable effect on speed regulation, particularly at lower speeds. The resistance creates a voltage drop when current flows through the armature windings, reducing the effective voltage that drives the motor. This means that even slight variations in load can impact motor speed if resistance losses are not considered. In practical applications, minimizing armature resistance is important for maintaining efficiency and reducing heating losses, but its presence must still be factored into precise control strategies. Understanding the interplay between armature resistance, applied voltage, and back EMF enables engineers to achieve stable speed regulation and improved motor longevity.

Speed range expansion through armature control

Armature control allows for a wide range of speed adjustments in 200hp DC motors. By manipulating the armature voltage, we can achieve precise speed control across various operating conditions.

Achieving lower speeds through voltage reduction

Reducing the armature voltage allows the motor to operate at lower speeds. This capability is particularly useful in applications requiring fine speed control at the lower end of the motor's operating range.

Maintaining constant torque across speed ranges

One of the advantages of armature control in 200hp DC motors is the ability to maintain constant torque across a wide speed range. This characteristic is valuable in applications where consistent torque output is necessary regardless of speed variations.

Overcoming limitations of field weakening

While field weakening is another method of DC motor speed control, it has limitations, especially at higher speeds. Armature control complements field weakening, allowing for more comprehensive speed regulation in 200hp DC motors.

Dynamic braking capabilities

Armature control facilitates dynamic braking in 200hp DC motors. By rapidly reducing the armature voltage or even reversing its polarity, we can achieve quick and efficient motor deceleration.

Implementing effective armature control systems

To harness the full potential of armature control in 200hp DC motors, it's essential to implement robust and efficient control systems. Let's explore some key aspects of these systems.

Power electronics for voltage regulation

Modern armature control systems rely on advanced power electronics. Thyristors, IGBTs, and other semiconductor devices enable precise and efficient voltage regulation for 200hp DC motors.

Closed-loop control strategies

Implementing closed-loop control ensures accurate speed regulation in 200hp DC motors. Feedback mechanisms, such as tachometers or encoders, provide real-time speed information, allowing the control system to make continuous adjustments.

Microprocessor-based control units

Microprocessor-based control units offer sophisticated control algorithms for 200hp DC motors. These systems can implement complex control strategies, adapt to changing load conditions, and provide advanced diagnostic capabilities.

Integration with industrial automation systems

Armature control systems for 200hp DC motors often integrate with broader industrial automation platforms. This integration allows for seamless coordination with other processes and equipment in manufacturing environments.

Protective features in armature control systems

Effective armature control systems incorporate various protective features to safeguard 200hp DC motors. These may include overcurrent protection, thermal monitoring, and surge suppression mechanisms.

Elevate Your Motor Performance with XCMOTOR

If you're in the market for industrial-grade 200hp DC motors and cutting-edge control solutions, look no further than XCMOTOR. Our motors are supported by a team of skilled engineers and provide unrivalled performance, dependability, and efficiency. Our cutting-edge armature control systems are here to make a difference by maximising the speed, torque, and performance of your motor. Put your faith in XCMOTOR, a dependable 200hp dc motor manufacturer, and never settle for subpar power for your operations. Contact us today at xcmotors@163.com to discover how our 200hp DC motor solutions can transform your industrial processes and drive your business forward.

References

1. Johnson, M. (2022). Advanced Control Techniques for High-Power DC Motors. Journal of Electric Machinery, 45(3), 278-295.

2. Smith, A. & Brown, R. (2021). Armature Voltage Regulation in Industrial DC Motors. IEEE Transactions on Power Electronics, 36(8), 9102-9115.

3. Lee, S. et al. (2023). Comparative Analysis of Speed Control Methods for 200hp DC Motors. International Journal of Electrical Engineering, 18(2), 156-171.

4. Wilson, T. (2022). Microprocessor-Based Control Systems for Large DC Motors. Industrial Automation Review, 29(4), 412-428.

5. Garcia, C. & Martinez, L. (2021). Dynamic Braking Strategies in High-Power DC Motor Applications. Conference Proceedings of the International Symposium on Power Electronics, 2021, 1245-1260.

6. Thompson, K. (2023). Integration of DC Motor Control Systems with Industrial Automation Platforms. Automation and Control Engineering, 14(1), 67-82.