Condensation in mining motors is a common challenge that can compromise the reliability and longevity of these critical devices. Mining motors, designed to operate in tough underground and industrial environments, face moisture accumulation due to temperature fluctuations and high humidity, which can degrade insulation, corrode components, and cause electrical failures. Preventing condensation through strategic design, maintenance, and advanced technologies is essential to ensure operational continuity and efficiency.

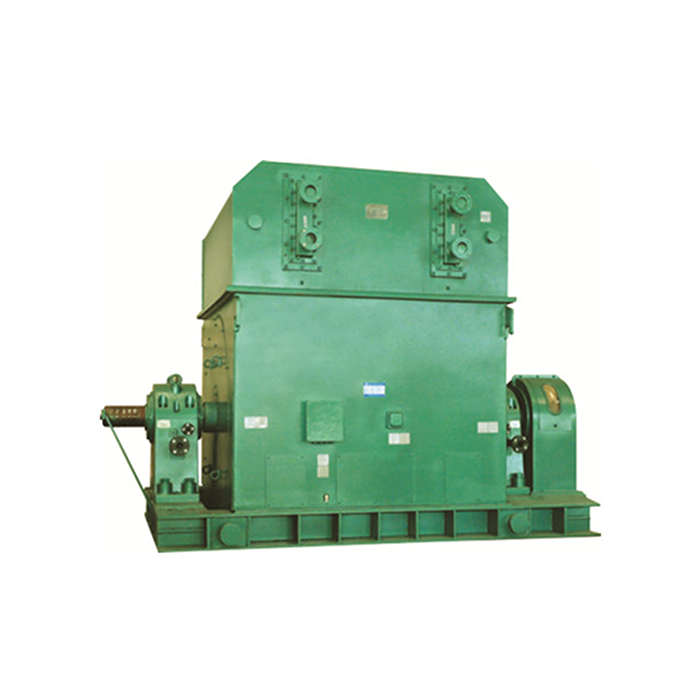

Series:T

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,

Power range:800-12000 kW

Application:fans, water pumps, compressors.

Advantage:large starting torque.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

The Impact of Condensation on Mining Motors

Mining motors are often subjected to harsh environments characterized by extreme humidity, temperature variations, and dusty air, which create ideal conditions for condensation. Moisture buildup inside the motor can severely impair its function, leading to corrosion of metal parts, degradation of insulation, and electrical short circuits. These detrimental effects not only reduce motor efficiency but also escalate maintenance costs and increase unplanned downtime.

What Causes Condensation in Mining Motors?

The primary cause of condensation inside mining motors stems from the interaction of environmental and operational factors. High humidity levels inherent in underground mines foster water vapor presence. When the motor surface temperature drops, especially during shutdowns or idle periods, water vapor condenses into liquid form within the motor housing.

Operational conditions such as irregular cycles and prolonged inactivity exacerbate this problem. For instance, when the motor cools down quickly after shutdown, the air inside cools and moisture condenses on cooler internal surfaces, including windings and bearings. Without proper ventilation or dehumidification measures, this moisture can accumulate, setting the stage for damage.

Consequences of Condensation in Mining Motors

Condensation affects the integrity of various motor components:

- Corrosion: Metal parts, including shafts and bearings, may corrode due to constant exposure to moisture, leading to premature failure.

- Electrical Failures: Moisture deteriorates the insulation systems of the windings, increasing the risk of short circuits and electrical breakdowns.

- Reduced Efficiency: Moisture accumulation causes insulation degradation and mechanical friction, causing the motor to consume more energy for the same output, which inflates operation costs.

Studies in industrial automation sectors have shown that motors exposed to uncontrolled humidity have up to 30% shorter service lives, underscoring the critical need for condensation control strategies.

Effective Strategies to Prevent Condensation in Mining Motors

Combating condensation requires a multi-layered approach combining proper environmental control and motor technologies. Mining operations can safeguard their motors by implementing well-designed ventilation systems and using anti-condensation heating techniques.

Implementing Proper Ventilation

Ventilation plays a vital role in maintaining dry conditions inside motor enclosures. Properly designed ventilation systems ensure adequate airflow, minimizing moisture accumulation. Key considerations for ventilation design include:

- Placement of air inlets to capture fresh, dry air and outlets to expel humid air efficiently.

- Use of filters to prevent ingress of dust while maintaining air quality.

- Ensuring ventilation paths avoid stagnant pockets where moisture can condense unnoticed.

Routine maintenance, such as cleaning vents and inspecting fans, sustains system efficacy. Regular checks prevent blockages and mechanical faults that would otherwise compromise airflow, thereby maintaining an environment unfavorable to condensation.

Utilizing Anti-Condensation Heaters

Anti-condensation heaters maintain the internal motor temperature above the dew point, significantly reducing moisture formation. Different heater types include:

- Immersion heaters embedded in motor windings.

- Surface-mounted strip heaters.

- Thermostatically controlled heaters for efficient energy use.

Professional installation is crucial to ensure adequate heat distribution without damaging components. Additionally, periodic testing and maintenance keep the heaters functioning optimally, thus extending motor life and reliability.

Advanced Technologies to Combat Condensation

Emerging innovations enhance the traditional approaches through real-time monitoring and protective advances.

Smart Sensors and Monitoring Systems

Installing smart humidity and temperature sensors inside motor housings allows operators to track environmental changes proactively. This data facilitates:

- Real-time alerts when moisture levels approach critical thresholds.

- Data-driven insights for maintenance scheduling based on environmental trends.

- Reduction of unexpected failures through predictive analytics.

Modern sensor networks can integrate seamlessly with plant-wide management systems, empowering teams with instant, actionable information.

Innovative Coating and Insulation Techniques

Protective coatings applied to windings and metal surfaces form moisture-resistant barriers, reducing corrosion risks. Advanced insulation materials, designed to withstand harsh underground conditions, further minimize moisture penetration. These solutions include:

- Epoxy-based varnishes with hydrophobic properties.

- High-grade mica insulation layers.

- Thermally stable and moisture-resistant polymer coatings.

These advanced materials extend motor service life and maintain performance even in extremely damp environments.

Choosing the Right Mining Motor for Condensation-Prone Environments

Selection of motors designed specifically for challenging environments directly impacts operational stability.

Features to Look for in a Mining Motor

Mines require motors engineered with resilience in mind. Key features include:

- Rugged Construction: Cast iron frames offer high-impact resistance, critical in long-term mining use.

- Moisture-Resistant Windings: Specialized coatings enhance corrosion resistance in humid conditions.

- High Starting Torque: Ensures reliable starting under heavy loads typical in fans, pumps, and compressors.

- Energy Efficiency: Motors with power factors above 0.85 reduce operational energy expenses.

Choosing motors with IP20 protection and insulation class F ensures compatibility with underground environments.

XCMOTOR: Leading Solutions for Mining Motor Challenges

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. stands at the forefront of mining motor technology. We offer power equipment tailored to the mining industry's demanding needs, with a focus on energy efficiency, reliability, and long-term operational stability.

Our Expertise in Mining Motor Technology

Our mining motors provide:

- Power ranges from 800 to 12,000 kW with voltage options spanning 3000V±5% to 10000V±5%, accommodating diverse mining applications such as fans, water pumps, and compressors.

- Robust cast iron frames and reinforced bearings configured to withstand high vibration and dusty environments.

- Unique moisture-resistant coatings on windings to prevent condensation-related damage.

- Compatibility with trusted bearing brands like SKF, NSK, and FAG, tailored per customer requirements.

These advantages ensure that XCMOTOR solutions reduce downtime, enhance productivity, and extend maintenance intervals — critical success factors in the industrial automation and mining sectors.

Conclusion

Condensation is a critical risk factor affecting mining motor longevity and operational efficiency. Identifying environmental and operational causes enables targeted preventive measures such as improved ventilation, anti-condensation heating, and protective coatings to mitigate moisture damage. Investing in technologically advanced, purpose-built mining motors ensures sustained performance under tough conditions. XCMOTOR's engineering expertise and commitment to quality make us a trusted partner in safeguarding your mining equipment investments and optimizing uptime.

Frequently Asked Questions

Q1: What are the common signs of condensation in mining motors?

A: Early symptoms include noticeable rust on metallic parts, damp insulation of windings, intermittent electrical faults, and unexplained increases in energy consumption. Regular inspections help detect these signs before severe damage occurs.

Q2: How often should anti-condensation measures be reviewed?

A: It is advisable to conduct a thorough review of condensation prevention systems at least annually, with seasonal checks during periods of high humidity or extended motor inactivity, to ensure all heating elements and ventilation systems operate effectively.

Q3: Can condensation issues be completely eliminated in mining motors?

A: Absolute elimination is challenging due to environmental variability; however, effective use of ventilation, heating, coatings, and continuous monitoring can drastically minimize the risk and impact of condensation, ensuring robust motor performance.

Where to Buy mining motor

Discover high-performance mining motors tailored for condensation-prone environments at XCMOTOR. As a trusted mining motor supplier, we offer products that combine rugged durability, advanced moisture-resistant technologies, and customizable bearing options from SKF, NSK, and FAG to meet the diverse needs of mining operations. Our motors are designed to withstand harsh conditions, ensuring optimal performance and longevity in demanding environments. To learn more or request a quote, contact us at xcmotors@163.com. Take the first step toward enhancing your mining equipment reliability today.

References

- Powell, A. & Johnson, L. “Moisture Management in Electrical Machines,” IEEE Transactions on Industry Applications, 2020.

- Smith, R. “Enhancing Mining Motor Reliability through Advanced Insulation and Coatings,” Journal of Mining Engineering, 2019.

- International Electrotechnical Commission. IEC 60034 Series – Rotating Electrical Machines Standards, Edition 2018.

- Jones, T. “Ventilation Design Principles for Industrial Motor Enclosures,” Industrial Cooling Systems Magazine, 2021.

- National Electrical Manufacturers Association. NEMA MG 1-2016: Motors and Generators Guide.

- Lee, S. & Carter, M. “Predictive Maintenance of Motors Using Smart Sensors,” Sensors and Actuators A, 2022.