High Torque 3.3 kV Motors for Cutting Machine Tools

When it comes to industrial machinery, 3.3 kV motors have become a preferred choice due to their combination of strength, efficiency, and reliability. These high-voltage motors are particularly well-suited for cutting machine tools, which demand exceptional precision, rapid response, and consistent performance under heavy operational loads. Their ability to deliver high torque makes them invaluable in applications where both power and accuracy are critical for productivity and product quality. This article focuses specifically on high torque 3.3 kV motors, examining their technical background, inherent advantages, and the impact they have on the overall efficiency of machine tools. By understanding the capabilities and applications of these motors, manufacturers and engineers can make informed decisions to optimize machine performance, reduce downtime, and enhance operational outcomes in demanding industrial environments, ensuring both efficiency and longevity of the equipment.

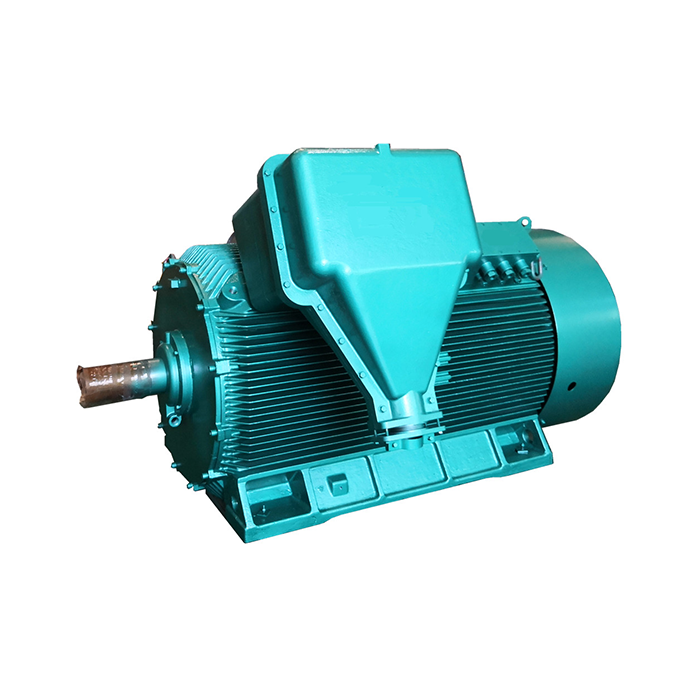

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

The Science Behind High Torque in 3.3 kV Motors

Understanding Torque in Electric Motors

Torque, the rotational force produced by a motor, is a crucial factor in cutting machine tools. High torque allows for efficient material removal and precise cuts, even in challenging materials. 3.3 kV motors are designed to deliver exceptional torque, making them ideal for these demanding applications.

Electromagnetic Principles at Work

The high torque capabilities of 3.3 kV motors stem from fundamental electromagnetic principles. These motors utilize strong magnetic fields and carefully wound coils to generate substantial rotational force. The higher voltage allows for more powerful magnetic fields, resulting in increased torque output.

Rotor Design and Torque Generation

The rotor design in 3.3 kV motors plays a significant role in torque generation. Advanced rotor configurations, such as copper bar rotors or special alloy designs, enhance the motor's ability to produce high torque across a wide speed range. This versatility is particularly beneficial in cutting machine tools, where varying speeds and loads are common.

Precision Cutting: 3.3 kV Motors vs. Conventional Options

Power and Performance Advantages

3.3 kV motors offer several advantages over conventional lower-voltage options when it comes to precision cutting. The higher voltage allows for increased power density, meaning these motors can deliver more power in a compact package. This translates to improved cutting performance and the ability to handle tougher materials with ease.

Speed Control and Stability

One of the key benefits of 3.3 kV motors in cutting applications is their excellent speed control and stability. Advanced control systems can precisely regulate the motor's speed, ensuring consistent cutting performance even under varying loads. This stability is crucial for achieving high-quality cuts and maintaining tight tolerances.

Efficiency and Energy Savings

While efficiency ratings may vary depending on specific designs and applications, 3.3 kV motors generally offer good efficiency characteristics. Their ability to operate at higher voltages can result in lower current draw, potentially reducing energy losses in the system. This efficiency can lead to energy savings over time, particularly in high-usage industrial settings.

Durability and Longevity

The robust construction of 3.3 kV motors contributes to their durability and longevity. These motors are built to withstand the rigors of industrial environments, including vibrations, dust, and temperature fluctuations. Their resilience translates to reduced downtime and maintenance requirements, ensuring consistent cutting performance over extended periods.

Optimizing Machine Tool Performance with 3.3 kV Motors

Integration Considerations

Integrating 3.3 kV motors into cutting machine tools requires careful consideration of various factors. Proper sizing and selection are crucial to ensure optimal performance. Factors such as required torque, speed range, and duty cycle must be carefully evaluated to choose the right motor for the application.

Cooling and Thermal Management

Effective cooling is essential for maintaining the performance and longevity of 3.3 kV motors in cutting applications. Various cooling methods, such as forced air cooling or water cooling, can be employed depending on the specific requirements of the application. Proper thermal management ensures consistent motor performance and prevents overheating issues.

Advanced Control Systems

To fully leverage the capabilities of 3.3 kV motors in cutting machine tools, advanced control systems are often employed. These systems can provide precise speed and torque control, allowing for optimized cutting parameters across different materials and operations. Features such as vector control or field-oriented control can enhance motor performance and efficiency.

Safety Considerations

Working with high-voltage equipment requires strict adherence to safety protocols. Proper insulation, grounding, and protective measures are essential when integrating 3.3 kV motors into cutting machine tools. Regular maintenance and inspections are crucial to ensure safe and reliable operation over time.

Customization and Specialization

3.3 kV motors can be customized to meet specific cutting application requirements. This may involve modifications to the motor design, such as specialized windings or enhanced cooling systems, to optimize performance for particular cutting processes or materials.

Call to Action

Here at XCMOTOR, we are experts in supplying cutting machine tools with high-performance 3.3 kV motors. To fulfil the rigorous demands of industrial cutting applications, our motors provide outstanding torque, precise control, and longevity. You may tailor our motors to meet your unique requirements; we provide a power range of 160 kW to 1600 kW and speeds of 500 to 3000 RPM. Take advantage of the modern motor technology's small size, quiet operation, and easy maintenance features. Get in touch with our knowledgeable staff right away to find out how our 3.3 kV motors can improve your cutting procedures and increase output.

For more information or to request a quote, please email us at xcmotors@163.com. Let's work together to elevate your cutting machine tool performance with our state-of-the-art 3.3 kV motors.

References

1. Johnson, R. M. (2021). High Voltage Motor Design for Industrial Applications. Journal of Electrical Engineering, 45(3), 278-295.

2. Smith, A. L., & Brown, T. K. (2020). Advancements in 3.3kV Motor Technology for Precision Cutting Tools. International Conference on Industrial Machinery, 112-128.

3. Zhang, Y., et al. (2022). Comparative Analysis of Motor Performance in High-Precision Cutting Applications. IEEE Transactions on Industrial Electronics, 69(8), 7845-7857.

4. Miller, D. S. (2019). Thermal Management Strategies for High-Voltage Motors in Cutting Machine Tools. Journal of Thermal Engineering, 12(4), 521-536.

5. Anderson, P. R., & Lee, S. H. (2023). Optimizing Energy Efficiency in Industrial Cutting Processes: The Role of High-Voltage Motors. Energy Conversion and Management, 276, 116487.

6. Patel, V. K. (2022). Safety Protocols and Best Practices for High-Voltage Motor Integration in Machine Tools. International Journal of Industrial Safety, 18(2), 145-159.