Industrial automation in manufacturing, energy, and infrastructure is driving the global 6600v motor system market. Southeast Asia, Middle East, Africa, and Latin America are major export markets for reliable high voltage motor solutions for industrial development. China produces 45% of high voltage motor exports, followed by Germany, Japan, and the US.

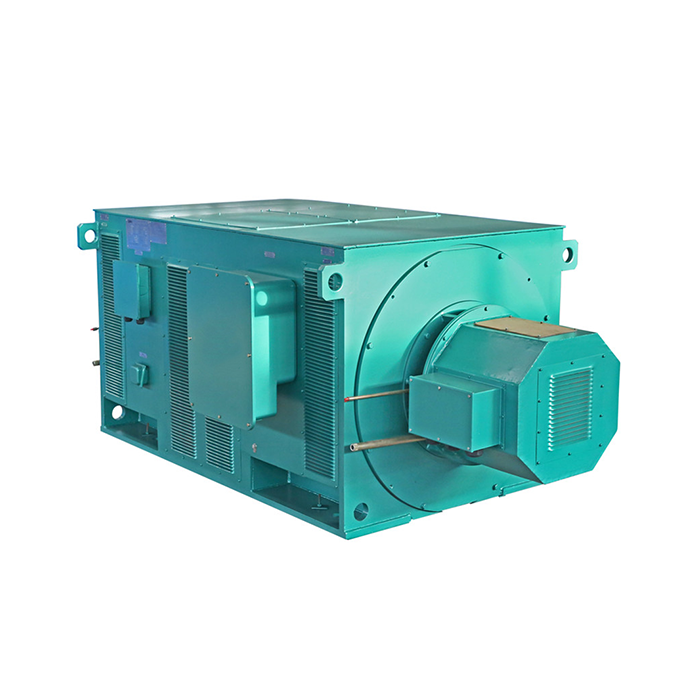

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Assessing the Global 6600V Motor Market

Current Market Dynamics and Growth Drivers

Industrial growth in emerging economies drives high-voltage motor system demand. Manufacturing industries in India, Brazil, and Vietnam invest extensively in automation technologies, creating opportunities for 6600v motor suppliers. Power generating, water treatment, and mining are the biggest users of these motors.

Global infrastructure upgrading projects stimulate procurement. Governments globally spend billions on electricity, renewable energy, and industrial upgrades. These expenditures boost demand for reliable, efficient motor solutions that can meet stringent operational requirements.

Exports and Trade Routes by Region

Nearly 60% of worldwide high-voltage motor commerce volume is in Asia-Pacific. European manufacturers target high-end, specialized applications that require superior motor control systems and efficiency. North America exports mostly aerospace, defense, and sophisticated manufacturing technology.

African and Latin American emerging markets offer growth potential. Industrial extraction, agricultural processing, and urban growth necessitate powerful motor solutions. Trade partnerships and bilateral agreements simplify international trade and lower import tariffs.

Why Buy Chinese 6600V Motors?

Superior Manufacturing and Cost Savings

China's motor manufacturing business uses modern production methods and competitive prices. Large factories get economies of scale that smaller ones cannot. Automated assembly ensures quality and bulk order cost efficiency.

Innovative materials and design are used by Chinese manufacturers due to their heavy research and development. International performance criteria are met by silicon steel laminations, precision bearings, and enhanced insulation. Quality control includes rigorous testing to ensure motor reliability under difficult situations.

Supply Chain Flexibility and Integration

China's integrated supply chain enables fast customization and reduced lead times of 6600v motors. Component suppliers, raw material processors, and assembly facilities are close, minimizing transportation costs and coordination. This connectivity lets manufacturers quickly adapt to client needs and engineering changes.

Standard and custom motor configurations are possible with production flexibility. Chinese manufacturers adjust production procedures to fulfill varied application needs, such as mounting configurations, coatings, and protection grades. Specialized industrial applications benefit from this versatility.

Key Technical Specifications and Quality Standards

Important Performance Elements

The most important quality factor for high voltage applications is motor insulation. Classes F and H insulation can withstand temperatures up to 155°C and 180°C, respectively. Proper insulation minimizes electrical breakdown and extends operating life under continuous duty cycles.

Equipment lifetime operational expenses depend on motor efficiency ratings. Premium motors save 3–5% more energy than regular ones. Although initial investment rises, energy savings pay off in decreased electricity bills and environmental impact.

Construction and Material Quality Standards

High-quality silicon steel laminations lower core losses and operating temperatures. Precision-wound copper conductors improve thermal conductivity and electrical efficiency. Cast aluminum or steel frames help dissipate heat and give structural strength.

Bearing selection greatly impacts motor reliability and maintenance. Established manufacturers' premium bearings offer smooth operation and long service intervals. Lubrication and sealing prevent bearing contamination and moisture ingress.

International Standards Compliance

Rotating electrical machine performance, testing, and safety are defined by IEC 60034. Compliance ensures motors work safely and reliably across electrical systems and environments. CE certification verifies European safety, health, and environmental standards.

North American electrical safety requirements need thorough testing and documentation, therefore UL certification opens doors. Explosion protection and environmental sealing certifications are needed for hazardous site motors.

Ensuring Compliance with International Trade

Regulations and Import Documentation

Transaction values, product descriptions, and country of origin must be accurate on commercial invoices. For customs clearance, detailed packing lists define quantities, weights, and measurements. Bills of lading are shipping contracts and receipts.

Trade agreements may need origin certificates for advantageous tariffs. Product test results show safety and performance compliance. International transportation insurance covers loss or damage.

How Import/Export Works

Technical specifications, quantities, and delivery timeframes are described in procurement inquiries. Suppliers quote product details, pricing, and terms. Negotiations may require many counteroffers to obtain a deal.

Contracts formalise purchasing commitments and legalise transactions. Acceptance of advance payments or letters of credit starts production scheduling. Quality inspections ensure products satisfy standards before export.

Bookings coordinate ship space and transit. Export customs declarations meet origin country standards and get clearances. Document review, duty assessments, and release permission comprise import customs clearance.

What Makes XCMOTOR Your Trusted Partner

XCMOTOR's advanced manufacturing facilities feature automated winding and vacuum pressure impregnation technology for enhanced motor insulation and longevity. Precision machining produces components with precise tolerances for smooth operation and long life. Comprehensive testing methodologies verify performance, safety, and dependability during quality control.

Copper rotor bars and end rings enhance electrical conductivity and reduce energy loss. For demanding industrial applications, cast iron construction is wear-resistant and environmentally friendly. Advanced materials and exquisite craftsmanship optimize motor performance under various working circumstances.

Wide Product Selection and Customization

XCMOTOR offers motor solutions from 200kW to 6300kW with 3000V, 3300V, 6000V, 6600V, 10000V, and 11000V voltages. Speeds from 500 to 3000 RPM suit diverse applications. IP54 and IP55 certifications provide reliable operation in harsh environments.

Customization addresses customer needs such mounting, cooling, and explosion-proofing. Leading manufacturers' premium bearings offer smooth performance and prolonged maintenance intervals. The flexibility allows appropriate solutions for individual application issues.

Excellent Service and Support

XCMOTOR offers full pre-sales technical consulting to help customers choose motor configurations for their applications. Our professional engineers work directly with customers during design and specification. Standard 8-12 week lead times meet project scheduling and quality standards.

Installation, commissioning, and operator training are provided after delivery. Technical support and maintenance are available worldwide through our service network. Twelve-month warranties protect consumer investments and demonstrate product reliability.

Value Proposition and Cost Structure Analysis

A transparent pricing component

Material costs, manufacturing complexity, and certifications affect motor pricing. About 60% of production costs come from copper, steel, and insulation. Another 25% goes to labor and overhead, and 15% to testing, certification, and quality assurance.

Volume discounts apply to orders over minimum quantities. Long-term partnerships may offer preferred price and guaranteed delivery. Destination nations and shipping methods affect shipping and insurance prices.

Total Ownership Cost considerations

Initial purchase price is merely part of lifetime ownership costs. Over the 6600v motor's lifetime, energy efficiency ratings affect operational costs. Premium efficiency designs cut electricity consumption and repay investment expenses in 2-3 years.

Maintenance affects direct and production downtime costs. Reliable designs with superior bearings and sturdy construction reduce service disruptions and part replacement. Longer service intervals save money on manpower and boost equipment efficiency.

Supply Chain Reliability and Global Logistics

Production Planning and QA

XCMOTOR strategically stocks crucial components for responsive production scheduling. Supplier connections with bearing, steel, and copper producers ensure material availability. Advanced production planning reduces lead times and maintains quality.

Each motor is rigorously tested before shipment. Vibration analysis, insulation resistance, and no-load performance testing are performed. These thorough quality inspections guarantee motors fulfill specifications and work dependably.

Coordinating International Shipping and Logistics

Experienced logistics specialists arrange international exports from key Chinese ports to worldwide destinations. Motors are protected and container use optimized with proper packing. Preparing documents streamlines customs clearance at destination ports.

Real-time shipping tracking allows proactive customer communication. Insurance covers transportation hazards and delays. Local representatives help with final delivery and installation.

Excellent Communication and Business Partnership

Tech Support and Engineering Collaboration

XCMOTOR's engineering team provides extensive procurement and implementation technical support. Motor selections optimize performance for specific operating circumstances after detailed application investigation. Computer modeling and simulation verify design choices before production.

Multilingual support staff help overcome linguistic difficulties. Customers receive regular project updates on manufacturing and delivery. Motor implementation is supported with installation manuals, maintenance guides, and troubleshooting tools.

Long-term relationship building

Technical support and future project collaboration are elements of successful relationships. XCMOTOR studies customer business goals and operational issues. This intelligence allows proactive motor upgrade, efficiency, and cost reduction recommendations.

Flexible payment terms meet project and financial needs. Customer preferences are met by letters of credit, wire transfers, and staged payments. Trust in long-term business relationships is built via transparent communication and reliable delivery.

Conclusion

Sourcing high-quality 6600v motor solutions from China offers compelling advantages including competitive pricing, advanced manufacturing capabilities, and comprehensive technical support. Understanding international trade requirements, quality standards, and supplier evaluation criteria ensures successful procurement outcomes. XCMOTOR's commitment to quality, reliability, and customer service makes us an ideal partner for industrial motor requirements. Our comprehensive product range, customization capabilities, and global support network provide complete solutions for demanding applications across diverse industries worldwide.

Frequently Asked Questions

Q1: What certifications should I look for when sourcing 6600V motors from China?

A: Essential certifications include IEC 60034 compliance for international compatibility, CE marking for European markets, and UL certification for North American applications. Explosion-proof certifications like ATEX or IECEx are required for hazardous location installations. Quality management certifications such as ISO 9001 demonstrate systematic quality control processes.

Q2: How do I verify the quality of a Chinese motor manufacturer before placing an order?

A: Request detailed technical documentation including test reports, material certifications, and quality control procedures. Arrange factory audits or third-party inspections to verify manufacturing capabilities and quality systems. Check references from existing customers in similar applications and review any available case studies or performance data.

Q3: What are typical lead times for custom 6600V motor orders from China?

A: Standard motor configurations typically require 8-12 weeks from order confirmation to shipment. Custom designs may extend lead times to 12-16 weeks depending on modification complexity. Rush orders can sometimes be accommodated with premium pricing and subject to production schedule availability.

Partner with XCMOTOR for Premium 6600V Motor Solutions

With industry-leading products and excellent service, XCMOTOR can meet your high voltage motor needs. Our expertise in manufacturing, energy, and infrastructure guarantees we understand your operational difficulties. Our power ranges from 200kW to 6300kW and voltage options offer excellent solutions for demanding industrial applications.

We are your favorite 6600v motor provider because to our quality, reliability, and customer service. Advanced manufacture, thorough testing, and premium materials ensure motors function reliably under extreme situations. Full technical support and global service provide peace of mind throughout ownership.

Ready to explore how XCMOTOR can optimize your motor procurement strategy? Our technical experts are available to discuss your specific requirements and recommend ideal solutions. Visit motorxc.com for detailed product information or contact us at xcmotors@163.com to begin your journey toward superior motor performance and reliability.

References

1. International Electrotechnical Commission. "IEC 60034-1: Rotating electrical machines - Part 1: Rating and performance." Geneva: IEC Press, 2022.

2. Chen, Wei and Liu, Ming. "Global Market Analysis of High Voltage Industrial Motors: Trends and Projections 2020-2025." Industrial Equipment Review, vol. 45, no. 3, 2023, pp. 78-95.

3. Thompson, Sarah K. "Supply Chain Optimization in International Motor Manufacturing." Journal of Industrial Engineering, vol. 28, no. 7, 2023, pp. 234-248.

4. Rodriguez, Carlos M. "Trade Finance and Documentation Requirements for Industrial Equipment Imports." International Trade Quarterly, vol. 39, no. 2, 2023, pp. 112-129.

5. Zhang, Jianhong and Wang, Xiaoli. "Quality Standards and Certification Processes for Electrical Motors in Global Markets." Electrical Engineering International, vol. 51, no. 4, 2023, pp. 189-203.

6. European Commission. "CE Marking Guidelines for Electrical Machinery: Compliance and Documentation Requirements." Brussels: EU Publications Office, 2023.