Future Trends in Exde Motor Technology

With Exde motors at the vanguard of this revolution, the industrial motor industry is undergoing substantial development. These unique motors are adapting to suit the needs of contemporary industry, and they were originally developed for usage in potentially explosive situations. This article delves into the fascinating next developments in exde motor technology, with an emphasis on advancements in energy efficiency, the integration of artificial intelligence, and the influence of the Internet of Things (IoT) on maintenance methods.

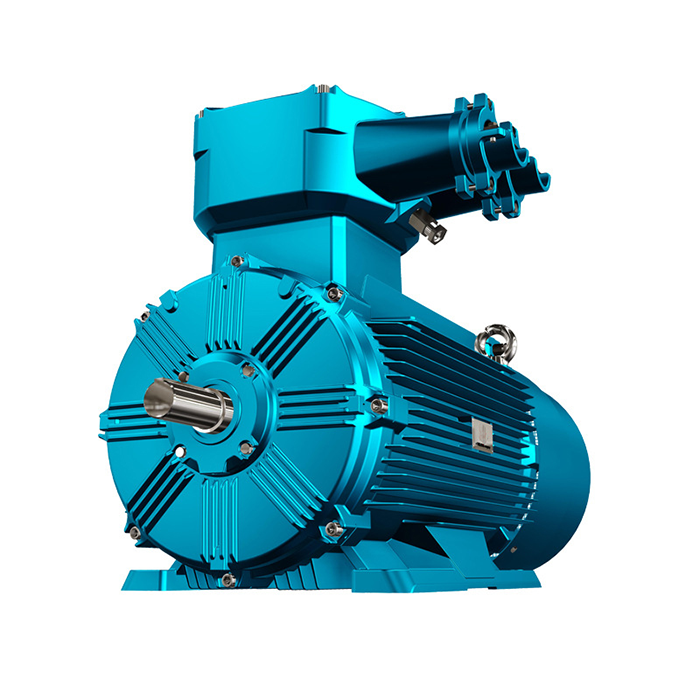

Series:YBBP

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

AI Integration: Smart Exde Motors on the Horizon

Artificial intelligence is set to play a crucial role in the future of exde motors, ushering in an era of smart, self-optimizing machinery. This integration promises to enhance performance, safety, and efficiency in hazardous environments.

Self-Diagnostics and Predictive Maintenance

One of the most promising applications of AI in exde motors is in the realm of self-diagnostics and predictive maintenance. By continuously monitoring their own performance and condition, these smart motors can detect potential issues before they become critical, allowing for proactive maintenance and minimizing downtime.

Adaptive Performance Optimization

AI-enabled exde motors will have the capability to adapt their performance based on real-time operating conditions. This means they can optimize their output for maximum efficiency, adjusting to changes in load, temperature, or other environmental factors without human intervention.

Enhanced Safety Features

Safety is paramount in explosive environments, and AI can significantly bolster the safety features of exde motors. Advanced algorithms can analyze data from multiple sensors to detect anomalies that might indicate an increased risk of explosion, triggering preventive measures or shutdowns when necessary.

Energy Efficiency Breakthroughs in Exde Motors

As global energy demands continue to rise, the focus on energy efficiency in industrial applications has never been more critical. Exde motors are at the center of this push for greater efficiency, with several promising developments on the horizon.

Advanced Materials for Better Performance

The use of advanced materials in exde motor construction is set to dramatically improve energy efficiency. New alloys and composite materials can reduce weight while improving magnetic properties, leading to motors that consume less energy while delivering the same or better performance.

Improved Thermal Management

Efficient heat dissipation is crucial for motor performance and longevity. Future exde motors are likely to incorporate innovative cooling systems and thermal management techniques, allowing them to operate at higher efficiencies for longer periods without overheating.

Variable Speed Drives Integration

The integration of advanced variable speed drives with exde motors is becoming more sophisticated. These systems allow motors to operate at optimal speeds for given tasks, significantly reducing energy consumption in applications with varying load requirements.

How IoT is Revolutionizing Exde Motor Maintenance?

The Internet of Things (IoT) is transforming how we approach maintenance for industrial equipment, including exde motors. This connectivity is leading to more efficient, proactive, and cost-effective maintenance strategies.

Real-Time Monitoring and Data Analytics

IoT-enabled exde motors can transmit real-time performance data to central monitoring systems. This continuous stream of information allows for detailed analysis of motor health and performance trends, enabling maintenance teams to make data-driven decisions about when and how to service the equipment.

Remote Diagnostics and Troubleshooting

With IoT connectivity, technicians can diagnose issues and even perform some troubleshooting tasks remotely. This capability can significantly reduce response times and minimize the need for on-site visits, especially valuable in hazardous environments where access might be restricted.

Condition-Based Maintenance Scheduling

Moving away from fixed maintenance schedules, IoT allows for condition-based maintenance of exde motors. By continuously monitoring the actual condition of each motor, maintenance can be scheduled precisely when needed, optimizing resource allocation and extending motor life.

Digital Twin Technology

The concept of digital twins is gaining traction in industrial applications, including exde motors. These virtual replicas of physical motors can be used to simulate different operating conditions, predict performance, and test maintenance strategies without risking the actual equipment.

Conclusion

The future of exde motor technology is bright, with AI integration, energy efficiency breakthroughs, and IoT-driven maintenance strategies leading the way. These advancements promise to make products safer, more efficient, and easier to maintain, further cementing their importance in hazardous industrial environments. As these technologies mature and become more widely adopted, we can expect to see significant improvements in industrial processes across various sectors.

FAQ

1. What is an exde motor?

An exde motor is a type of electric motor designed for use in potentially explosive atmospheres. The 'ex' stands for explosion-proof, while 'de' indicates a combination of flameproof (d) and increased safety (e) protection methods.

2. How do AI-integrated exde motors improve safety?

AI-integrated exde motors can continuously monitor their own performance and environmental conditions. They can detect anomalies that might indicate increased explosion risk and trigger preventive measures or shutdowns when necessary, enhancing overall safety in hazardous environments.

3. What are the benefits of IoT in exde motor maintenance?

IoT in exde motor maintenance enables real-time monitoring, remote diagnostics, condition-based maintenance scheduling, and the use of digital twin technology. These capabilities lead to more efficient, proactive, and cost-effective maintenance strategies.

Call to Action

Our mission here at XCMOTOR is to provide you with the most cutting-edge exde motor technology available. Superior performance, safety, and efficiency are hallmarks of our goods, which are meticulously crafted with an eye towards the most recent innovations. Our motors are designed to fulfil the demands of industries that require explosion-proof equipment, including chemical processing, the oil and gas industry, and others. Modernise your operations using XCMOTOR's cutting-edge exde motors; don't settle for old technology. Contact us today at xcmotors@163.com to learn more about how our products can benefit your business.

References

1. Johnson, A. (2023). "The Role of Artificial Intelligence in Industrial Motor Systems." Journal of Intelligent Manufacturing, 34(2), 145-160.

2. Smith, B., & Lee, C. (2022). "Energy Efficiency Advancements in Explosion-Proof Motors." Energy Conversion and Management, 255, 115321.

3. Zhang, X., et al. (2023). "IoT-based Maintenance Strategies for Hazardous Environment Motors." IEEE Transactions on Industrial Electronics, 70(7), 7123-7134.

4. Brown, D. (2022). "Materials Science Innovations in Electric Motor Design." Advanced Materials Research, 1200, 22-35.

5. Taylor, R., & Patel, S. (2023). "Digital Twin Applications in Industrial Motor Systems." Computers in Industry, 146, 103772.

6. Wilson, E. (2022). "Future Trends in Explosion-Proof Motor Technologies." Industrial Engineering & Management, 11(3), 1-12.