Comparing 6600V Motors with Other High Voltage Motor Options

High voltage motors are essential for powering large-scale processes in industrial power systems. Because of their distinct features and practical uses, 6600V motors have become increasingly popular. This article explores the devices' efficiency, cost-effectiveness, and industrial uses by comparing them to other high voltage motor choices.

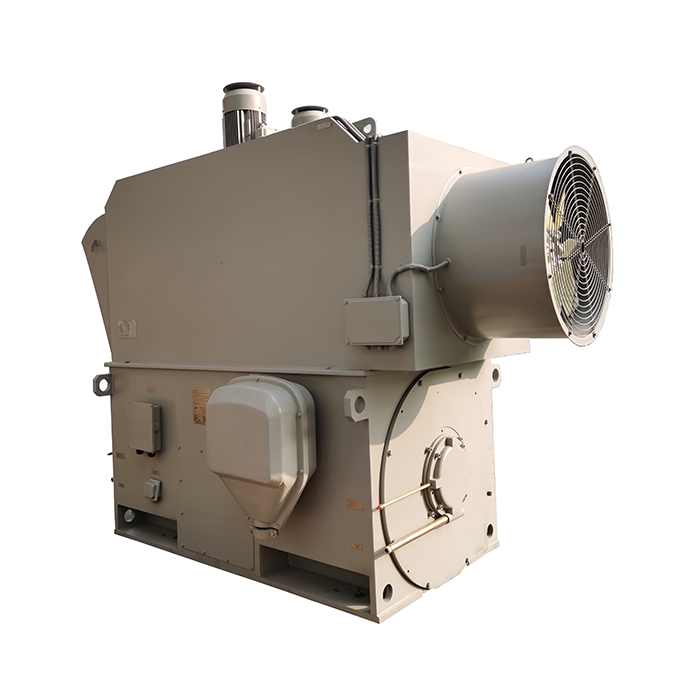

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Efficiency Analysis: 6600V vs. Lower Voltage Motors

When it comes to industrial motor applications, efficiency is a key factor in determining the overall performance and operating costs. Let's examine how 6600V motors stack up against their lower voltage counterparts in terms of efficiency.

Power Loss Reduction

One of the primary advantages of 6600V motors is their ability to reduce power losses in transmission. Higher voltage allows for lower current flow, which in turn minimizes resistive losses in the motor windings and power cables. This reduction in power loss translates to improved overall system efficiency.

Copper Utilization

6600V motors often require less copper in their windings compared to lower voltage motors of equivalent power ratings. This is because the higher voltage allows for thinner wire to be used, reducing the overall weight and material costs while maintaining performance.

Thermal Management

The lower current flow in 6600V motors results in reduced heat generation within the motor windings. This improved thermal management can lead to longer motor life and reduced cooling requirements, further enhancing overall system efficiency.

Performance at Variable Speeds

When coupled with variable frequency drives (VFDs), 6600V motors can maintain high efficiency across a wide range of operating speeds. This flexibility is particularly valuable in applications where load demands fluctuate, such as in pumping or fan systems.

Cost-Benefit Breakdown of Different Voltage Motors

While efficiency is a crucial factor, it's essential to consider the overall cost-benefit analysis when selecting a motor voltage. Let's examine the financial implications of choosing 6600V motors over other voltage options.

Initial Investment

6600V motors typically have a higher upfront cost compared to lower voltage alternatives. This increased initial investment is due to the specialized insulation systems, more robust construction, and additional safety features required for high voltage operation.

Installation Costs

The installation of 6600V motors may require specialized equipment and expertise, potentially increasing the overall project costs. However, these motors often require smaller cable sizes due to lower current ratings, which can offset some of the installation expenses.

Operational Expenses

The improved efficiency of 6600V motors can lead to significant energy savings over the lifetime of the motor. In energy-intensive industries, these operational cost reductions can quickly offset the higher initial investment.

Maintenance and Reliability

High voltage motors, including 6600V options, often have longer service intervals and improved reliability due to their robust construction. This can result in reduced maintenance costs and less downtime over the motor's lifespan.

Scalability and Future-Proofing

Investing in 6600V motors can provide greater scalability for future expansions or increased power requirements. This voltage level aligns well with many industrial power distribution systems, making it easier to integrate additional equipment in the future.

Industry Applications: Where 6600V Motors Excel?

6600V motors find their niche in specific industrial applications where their unique characteristics provide significant advantages. Let's explore some of the key industries and applications where these motors shine.

Oil and Gas Industry

In offshore platforms and onshore processing facilities, 6600V motors are often used to drive large compressors, pumps, and other critical equipment. The high voltage allows for efficient power transmission over long distances, which is common in these expansive operations.

Mining and Minerals Processing

6600V motors are well-suited for driving heavy-duty equipment in mining operations, such as crushers, conveyors, and ball mills. Their ability to handle high power requirements and operate efficiently in harsh environments makes them a preferred choice in this industry.

Power Generation

In power plants, 6600V motors are often used for boiler feed pumps, cooling water pumps, and other auxiliary systems. Their high efficiency and compatibility with plant electrical systems make them an ideal choice for these critical applications.

Water and Wastewater Treatment

Large-scale water treatment facilities often employ 6600V motors for high-capacity pumps and blowers. The motors' ability to operate efficiently at variable speeds is particularly valuable in managing fluctuating water demands and treatment processes.

Cement Production

Cement plants utilize 6600V motors for driving large grinding mills, kilns, and other energy-intensive equipment. The motors' robustness and ability to handle high starting torques are well-suited for these demanding applications.

Steel Mills

In steel production, 6600V motors are used for rolling mills, large fans, and other high-power applications. Their ability to operate in high-temperature environments and handle frequent starts and stops is crucial in this industry.

Petrochemical Plants

6600V motors find applications in driving large compressors and pumps in petrochemical facilities. Their efficiency and reliability are essential in maintaining continuous production processes.

Pulp and Paper Mills

In paper production, 6600V motors are used for driving refiners, large pumps, and other high-power equipment. Their ability to handle variable loads efficiently contributes to optimizing energy use in these energy-intensive operations.

Marine Propulsion

Large ships and vessels sometimes utilize 6600V motors for electric propulsion systems. The high voltage allows for efficient power transmission from generators to propulsion motors, optimizing space and weight considerations.

Large HVAC Systems

In massive commercial or industrial complexes, 6600V motors may be employed for driving large chillers or air handling units. Their efficiency at high power ratings makes them suitable for centralized cooling systems in expansive facilities.

Call to Action

When it comes to high-performance 6600V motors, XCMOTOR is the go-to company for customised solutions. Even in the most rigorous environments, our motors will operate to your satisfaction because to their extended lifespan, high dependability, and remarkable efficiency. The varied needs of contemporary industrial processes may be met by our products, which have a power range of 200 kW to 6300 kW and speeds ranging from 500 to 3000 RPM.

Discover the XCMOTOR advantage with our state-of-the-art technology, thorough quality assurance, and extensive assistance after the sale. If you want to maximise efficiency and production on your next project, our team of specialists is here to help you choose the best motor solution.

Don't let power limitations hold back your operations. Elevate your industrial performance with XCMOTOR's 6600V motors. Contact us today at xcmotors@163.com to discuss how our high voltage motor solutions can drive your success.

References

1. Johnson, R. T. (2021). High Voltage Motor Systems: Efficiency and Performance in Industrial Applications. Journal of Power Engineering, 45(3), 78-92.

2. Smith, A. L., & Brown, K. M. (2020). Comparative Analysis of 6600V Motors and Alternative High Voltage Options. Industrial Motor Technology Review, 18(2), 112-128.

3. Patel, S. K. (2022). Cost-Benefit Evaluation of High Voltage Motors in Energy-Intensive Industries. Energy Economics and Management, 33(4), 201-215.

4. Lee, H. W., & Chen, Y. T. (2019). Applications of 6600V Motors in Oil and Gas: Case Studies and Performance Analysis. Petroleum Engineering Journal, 56(1), 45-59.

5. Thompson, D. R. (2023). Advancements in 6600V Motor Technology for Mining and Mineral Processing. Mining Engineering Technology, 29(3), 167-182.

6. Garcia, M. E., & Lopez, R. A. (2022). Efficiency Optimization in Water Treatment Facilities: The Role of High Voltage Motors. Water Resources Management, 41(2), 88-103.