A 20 hp dc electric motor represents a powerful and versatile solution for medium to heavy-duty industrial applications across manufacturing, automation, and energy sectors. These robust electric motors deliver exceptional torque output while maintaining precise speed control capabilities that make them ideal for demanding operational environments. DC motors in this horsepower range provide superior efficiency and reliability for processes requiring variable speed operation, from manufacturing conveyor systems to water treatment pumps. Understanding the technical specifications, applications, and selection criteria for these motors enables engineers and procurement professionals to make informed decisions that optimize both performance and operational costs.

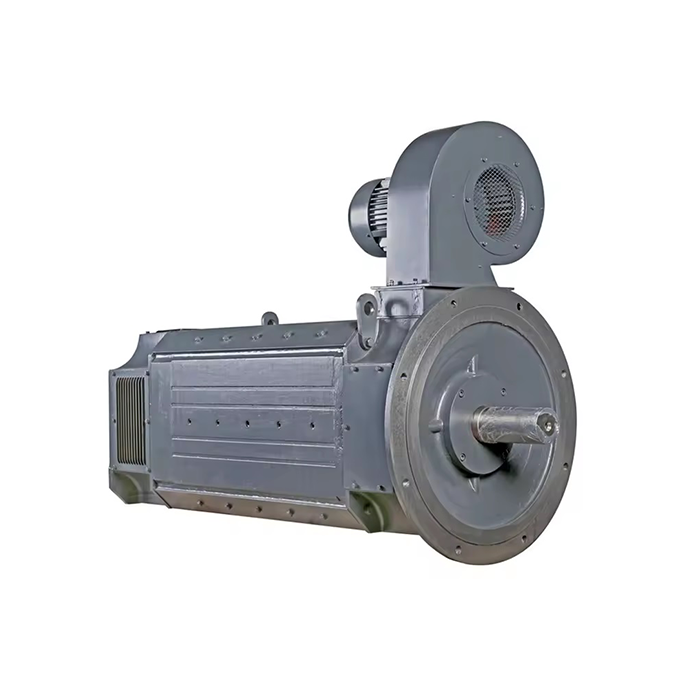

Series:Z4

Frame number: 100-450

Application:Z4 series motorsThis series of motors can be widely used in various industrial sectors such as metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, printing, cement, and plastic extrusion machinery.

Power range:1.5-600kW

Voltage range: 160V,440V, etc.

Certificate: The performance of this series of motors not only complies with the national standard GB/T755 "Basic Technical Requirements for Rotating Electrical Machines", but also basically complies with the German VDE0530 standard.

Advantage:Z4 series DC motor has greater advantages than Z2 and Z3 series. It can not only be powered by DC unit power supply, but also suitable for static rectifier power supply. It has small moment of inertia, good dynamic performance, and can withstand high load change rates. It is especially suitable for control systems that require smooth speed regulation, high efficiency, automatic speed stabilization, and responsive response. It has reached the current international advanced level..

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding 20 HP DC Motor Fundamentals

DC motors convert electrical energy into mechanical motion through electromagnetic principles that create rotational force on the motor shaft. The 20 horsepower rating indicates the motor's power output capacity under standard operating conditions, translating to approximately 14.9 kilowatts of mechanical energy.

These motors operate on direct current voltage, typically ranging from 180V to 480V depending on the specific application requirements. The armature windings interact with permanent magnet or electromagnet fields to generate torque that drives connected equipment. Motor controllers regulate current flow to achieve precise speed control and maintain consistent performance across varying load conditions.

Brushless designs eliminate physical contact between rotating and stationary components, significantly reducing maintenance requirements while extending operational lifespan. The absence of brushes also minimizes electrical noise and sparking, making these motors suitable for sensitive electronic environments found in modern manufacturing facilities.

Key Performance Characteristics

Efficiency and Energy Savings

Efficiency ratings for 20 hp dc electric motors are typically above 90%, making them far more efficient than older motor technologies. This high level of efficiency leads to significant energy savings, especially in industrial settings where motors are used continuously. The reduced energy consumption directly translates to lower electricity bills, making these motors an ideal choice for operations that need to control costs. Moreover, the reduced energy waste minimizes the generation of heat, contributing to a more sustainable and safer working environment.

Torque Characteristics and Performance

The torque characteristics of DC motors can vary considerably depending on the design. Some motors are designed to deliver maximum torque right at startup, which is particularly beneficial in applications that require heavy initial lifting or fast acceleration. On the other hand, some designs are optimized for more consistent torque delivery across the entire speed range. These motors can provide better performance when precise control over the torque is needed at different operating speeds, offering versatility in various applications.

Variable Speed Capabilities

One of the key advantages of modern DC motors is their ability to operate at variable speeds. These motors allow operators to adjust performance levels according to specific requirements, ranging from near-zero RPM (revolutions per minute) to maximum rated speeds that can exceed 3,000 RPM. This feature is particularly useful in applications that require precise control over speed, such as conveyor belts, pumps, or machine tools. By adjusting the motor speed, operators can optimize performance, reduce wear, and enhance overall system efficiency.

Load Capacity and Reliability

The load capacity specifications of DC motors define the maximum mechanical stress that the motor can endure without compromising performance or reliability. These specifications are crucial in high-demand applications where motors are subjected to heavy loads and continuous operation. A motor's load capacity ensures that it can operate under challenging conditions without failure. Proper thermal management, such as the inclusion of cooling systems, is essential for preventing overheating during such high-demand operations. This helps maintain consistent performance even in environments with extreme conditions.

Motor Winding Configurations and Voltage Requirements

The motor winding configuration plays a significant role in determining both the voltage requirements and the operational characteristics of DC motors. Series-wound motors, for example, are known for their high starting torque but have variable speed characteristics. These motors are often used in applications where high initial torque is needed but the speed can fluctuate. Shunt-wound motors, on the other hand, provide more stable speed regulation under varying load conditions. This makes them suitable for applications where maintaining a consistent speed, regardless of load fluctuations, is critical. Understanding these differences allows operators to select the best motor configuration for their specific needs.

Industrial Automation Applications

Manufacturing operations leverage 20 hp dc electric motors for conveyor systems, material handling equipment, and production line machinery requiring precise speed control. Automotive assembly lines utilize these motors for robotic positioning systems and automated welding equipment where accuracy and repeatability are critical.

Electronics manufacturing facilities employ DC motors in component placement machines and testing equipment where electromagnetic interference must be minimized. The smooth operation and controllable acceleration of DC motors prevent damage to sensitive electronic components during automated assembly processes.

Process control applications benefit from the instant torque delivery and variable speed capabilities of DC motors. Pump systems, valve actuators, and compressor drives rely on these motors to maintain precise flow rates and pressure levels throughout industrial processes.

Aerospace manufacturing requires motors that meet stringent quality standards while providing reliable performance in critical applications. DC motors power machining centers, assembly fixtures, and testing equipment used in aircraft component production.

HVAC and Refrigeration Systems

Commercial HVAC installations incorporate 20 HP DC motors in large air handling units, cooling tower fans, and chiller systems where energy efficiency directly impacts operational costs. Variable speed operation allows these systems to adjust airflow and cooling capacity based on real-time demand, optimizing energy consumption.

Refrigeration applications utilize DC motors for compressor drives and circulation pumps in cold storage facilities and food processing plants. The precise temperature control enabled by variable speed motors helps maintain product quality while reducing energy waste.

Residential HVAC systems benefit from DC motor technology in high-efficiency heat pumps and central air conditioning units. Quiet operation and smooth speed transitions improve occupant comfort while reducing electrical consumption compared to traditional motor technologies.

Energy and Utilities Implementation

Power generation facilities employ 20 hp dc electric motors in auxiliary systems including cooling water pumps, fuel handling equipment, and generator excitation systems. The reliability and controllability of DC motors support continuous power plant operations.

Renewable energy installations integrate DC motors into solar tracking systems that optimize panel positioning throughout the day. Wind turbine pitch control mechanisms rely on DC motors to adjust blade angles for maximum energy capture across varying wind conditions.

Water treatment operations utilize DC motors for chemical dosing pumps, filtration systems, and distribution network equipment. The precise control capabilities enable accurate chemical addition and flow regulation essential for water quality management.

Utility companies deploy DC motors in switchgear operations and transformer cooling systems where reliable performance directly affects grid stability and equipment protection.

Selection Criteria and Specifications

Voltage requirements must align with available power supply systems while considering efficiency optimization. Higher voltage motors typically offer improved efficiency but may require specialized electrical infrastructure and safety considerations.

Speed range specifications should accommodate both minimum and maximum operational requirements with adequate margin for varying load conditions. Gearbox integration may be necessary for applications requiring high torque at low speeds or precise positioning capabilities.

Environmental factors including temperature extremes, humidity levels, and exposure to chemicals or contaminants influence motor selection and required protection ratings. Enclosure types range from open designs for clean environments to sealed units for harsh industrial conditions.

Motor controller compatibility affects overall system performance and integration complexity. Advanced controllers provide features like regenerative braking, soft starting, and communication interfaces for automated control systems.

Installation and Maintenance Considerations

Proper mounting and alignment procedures ensure optimal motor performance and longevity. Foundation requirements depend on motor size, operational speeds, and vibration characteristics of the connected equipment.

Electrical connections must comply with local codes and manufacturer specifications to ensure safe operation and prevent premature failure. Proper grounding and circuit protection are essential for both safety and motor protection.

Preventive maintenance schedules should include regular inspection of electrical connections, bearing lubrication, and thermal monitoring. Brushless motors require minimal maintenance compared to brushed designs but still benefit from periodic professional inspection.

Performance monitoring systems can detect developing issues before they cause equipment failure. Vibration analysis, thermal imaging, and electrical parameter monitoring help optimize maintenance timing and prevent unexpected downtime.

Conclusion

20 HP DC electric motors provide versatile solutions for applications demanding precise speed control, high efficiency, and reliable performance across diverse industrial sectors. Understanding the technical characteristics, application requirements, and selection criteria enables informed decisions that optimize both operational performance and long-term costs. From manufacturing automation to energy generation, these motors deliver the power and control necessary for modern industrial operations. Proper selection, installation, and maintenance practices ensure maximum return on investment while supporting continuous operational excellence. Partner with experienced suppliers like XCMOTOR to access quality products and expert support that drive successful project outcomes.

Why Choose XCMOTOR for Your 20 HP DC Electric Motor Requirements

XCMOTOR stands as a trusted 20 hp dc electric motor supplier, delivering premium power equipment solutions that meet the demanding requirements of modern industrial applications. Our commitment to providing high energy efficiency, low energy consumption, and stable power output makes us the preferred choice for discerning engineers and procurement professionals.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. maintains rigorous quality standards, sourcing only original products from trusted brands to ensure reliable performance and longevity. Our comprehensive inventory includes various motor configurations to match specific application requirements across industrial automation, HVAC, energy, and utility sectors.

Our customer-focused approach includes fast delivery services with free shipping on all products, eliminating delays that can impact project timelines. The 30-day open purchase policy provides confidence in your motor selection, allowing adequate time for thorough testing and integration.

Technical expertise drives our dedicated support services, available seven days a week including weekends. Our engineering team provides prompt assistance with pre-sales consultation, technical specifications, and after-sales support to ensure optimal motor performance throughout its operational lifespan.

When your applications demand reliable 20 hp dc electric motor solutions backed by expert support and proven quality, contact us at xcmotors@163.com to discuss your specific requirements and discover how XCMOTOR can enhance your operational efficiency.