Installing a 6600v motor in industrial environments requires meticulous attention to safety protocols, technical specifications, and regulatory compliance. These high voltage electric motors serve as the backbone of critical industrial operations across manufacturing, power generation, and process control applications. The installation process involves multiple phases including site preparation, electrical connections, mechanical mounting, and comprehensive testing procedures. Proper installation ensures optimal energy efficiency, extended equipment lifespan, and safe operation under demanding industrial conditions.

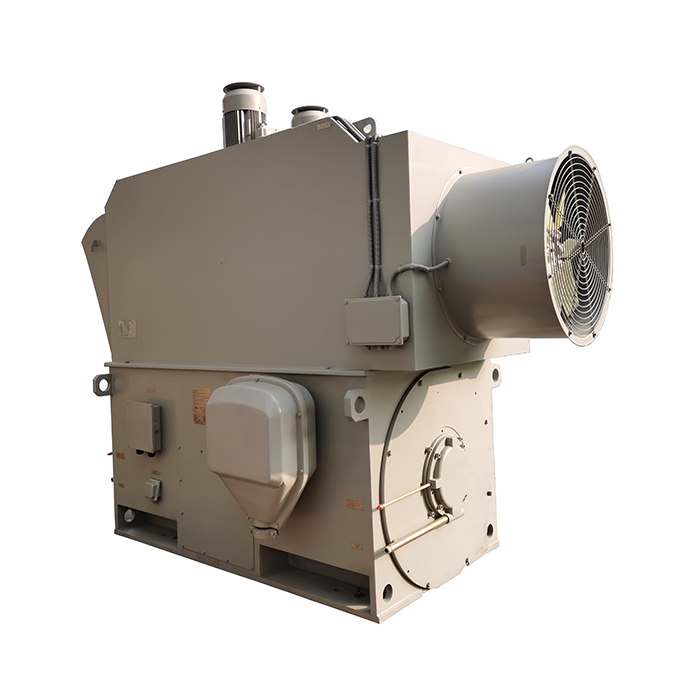

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Specifications of High Voltage Motor

Before beginning any installation project, understanding the specific requirements of your 6600v motor becomes paramount. High voltage electric motors operate at significantly different parameters compared to standard industrial motors. The voltage rating determines insulation requirements, safety clearances, and protective equipment specifications.

Motor specifications include power ratings typically ranging from 500 kW to several megawatts. Synchronous motors and induction motors represent the two primary types used in high voltage applications. Synchronous motors offer superior power factor correction capabilities, making them ideal for power generation facilities. Induction motors provide robust performance in variable load applications common in manufacturing environments.

Heavy machinery applications demand careful consideration of torque characteristics. Starting torque requirements vary significantly between different industrial applications. Process control systems often require precise speed regulation, while pumps and compressors may need high starting torque capabilities.

Environmental conditions significantly impact motor selection and installation requirements. Cooling system design must accommodate ambient temperatures, humidity levels, and potential contamination sources. Motor winding protection becomes critical in harsh industrial environments where dust, chemicals, or extreme temperatures exist.

Pre-Installation Safety Requirements

Safety protocols for high voltage motor installation exceed standard electrical work requirements. Personnel must receive specialized training in high voltage procedures before participating in installation activities. Electrical insulation testing equipment, personal protective equipment, and emergency response procedures require careful preparation.

Site isolation involves multiple steps beyond simple power disconnection. Lock-out tag-out procedures must account for all potential energy sources including stored electrical energy in capacitors, mechanical energy in connected equipment, and compressed air systems. Grounding procedures require verification using calibrated testing equipment.

Installation teams should include certified electricians with high voltage experience. Motor protection systems require configuration by qualified technicians familiar with the specific equipment being installed. Documentation of all safety procedures ensures compliance with industrial safety standards.

Workplace safety extends beyond electrical hazards. Heavy lifting equipment, proper ventilation for confined spaces, and fire suppression systems require consideration during installation planning. Emergency procedures must address potential electrical incidents, mechanical injuries, and evacuation requirements.

Foundation and Mounting Preparation

Foundation design directly impacts motor performance, reliability, and maintenance accessibility. Concrete foundations must cure completely before 6600v motor installation begins. Foundation dimensions account for motor weight, operating forces, and thermal expansion characteristics.

Vibration isolation becomes increasingly important as motor power increases. Proper foundation design minimizes vibration transmission to surrounding structures while maintaining precise alignment with driven equipment. Mounting bolt specifications require careful attention to material grades and torque requirements.

Alignment procedures demand precision measuring equipment and experienced technicians. Misalignment causes premature bearing failure, increased energy consumption, and potential coupling damage. Laser alignment tools provide the accuracy required for high-power motor installations.

Access requirements for ongoing maintenance influence foundation and mounting design decisions. Motor maintenance procedures require adequate clearance for component removal, cooling system service, and electrical connection inspection. Planning for future maintenance reduces downtime and extends equipment life.

Electrical Connection Procedures

High voltage electrical connections require specialized techniques and materials designed for 6600v applications. Cable selection must consider current carrying capacity, insulation ratings, and environmental conditions. Termination procedures follow strict protocols to ensure reliable long-term performance.

Motor control systems integration involves complex wiring schemes connecting the motor to variable frequency drives, protection relays, and automation systems. Control circuit wiring operates at different voltage levels requiring careful separation and identification. Wire routing must prevent electromagnetic interference while maintaining accessibility for troubleshooting.

Grounding systems require multiple connection points with verified continuity. Equipment grounding, system grounding, and lightning protection work together to ensure personnel safety and equipment protection. Ground resistance measurements confirm proper installation using specialized testing equipment.

Power supply connections require verification of phase rotation, voltage balance, and system grounding configuration. Incorrect connections can cause motor damage, reduced performance, or safety hazards. Testing procedures confirm proper electrical installation before energizing the motor.

Motor Protection and Control Systems

Motor protection systems safeguard expensive equipment from damage due to electrical faults, mechanical overloads, or environmental conditions. Protection relays monitor multiple parameters including current, voltage, temperature, and vibration. Proper configuration requires understanding of both motor characteristics and application requirements.

Variable frequency drive integration enables precise speed control and improved energy efficiency. Drive selection must match motor specifications while providing necessary control features. Programming parameters include acceleration rates, deceleration patterns, and protection settings specific to the application.

Automation integration connects motor control systems to plant-wide control networks. Communication protocols enable remote monitoring, data collection, and automated control sequences. Integration planning considers network security, data requirements, and operator interface needs.

Load capacity monitoring prevents motor overload while optimizing performance. Current monitoring, thermal protection, and mechanical load sensing work together to protect equipment while maximizing productivity. Alarm systems provide early warning of developing problems.

Testing and Commissioning Procedures

Comprehensive testing validates proper installation and ensures safe operation before placing equipment into service. Insulation resistance testing verifies electrical integrity using megohm meters designed for high voltage applications. Test results must meet or exceed manufacturer specifications and industry standards.

Motor winding testing includes resistance measurements, insulation testing, and polarization index calculations. These tests detect manufacturing defects, installation damage, or moisture contamination. Documentation of test results provides baseline data for future maintenance planning.

No-load testing verifies proper motor operation without connected loads. Vibration measurements, temperature monitoring, and current analysis confirm proper installation and alignment. Any abnormal readings require investigation and correction before proceeding with loaded testing.

Full-load testing demonstrates motor performance under actual operating conditions. Power factor measurements, torque verification, and thermal performance testing validate motor specifications. Cooling system effectiveness requires verification under full-load conditions.

Troubleshooting Common Installation Issues

Installation problems often manifest as vibration, overheating, or electrical faults. Systematic troubleshooting procedures help identify root causes and implement effective solutions. Common issues include misalignment, improper electrical connections, and inadequate cooling.

Vibration problems typically result from mechanical issues such as misalignment, imbalance, or foundation problems. Vibration analysis using specialized equipment identifies specific causes and guides corrective actions. Proper diagnosis prevents costly equipment damage and reduces maintenance requirements.

Electrical problems may indicate wiring errors, insulation failure, or protection system malfunctions. Systematic electrical testing isolates problems and guides repair procedures. Understanding normal operating parameters helps distinguish between installation problems and equipment defects.

Thermal issues often result from inadequate cooling, overloading, or environmental conditions. Temperature monitoring at multiple points helps identify heat sources and cooling system effectiveness. Proper thermal management ensures reliable operation and extends equipment life.

Industry-Specific Installation Considerations

Manufacturing environments present unique challenges including space constraints, production scheduling, and contamination control. Installation planning must minimize disruption to ongoing operations while ensuring quality results. Coordination with production teams prevents conflicts and reduces installation time.

Power generation facilities require strict adherence to grid interconnection standards and utility regulations. Installation procedures must maintain system reliability while ensuring personnel safety. Coordination with system operators prevents grid disturbances during installation activities.

Process control applications demand precise installation to maintain product quality and system stability. Motor performance directly impacts process variables requiring careful attention to installation details. Integration with existing control systems requires thorough testing and validation.

Renewable energy installations face environmental challenges and remote locations. Installation procedures must account for weather conditions, limited access, and specialized equipment requirements. Reliability becomes critical due to limited maintenance access and harsh operating conditions.

Conclusion

Successful installation of 6600v motors requires careful planning, skilled technicians, and attention to safety protocols. Understanding motor specifications, following proper installation procedures, and implementing comprehensive testing ensures reliable operation and long equipment life. Industry-specific considerations and environmental factors influence installation approaches across different applications. Proper installation directly impacts energy efficiency, reliability, and maintenance requirements throughout the motor's operational life. Working with experienced suppliers and technical support teams reduces installation risks and ensures optimal performance in demanding industrial environments.

Choose XCMOTOR as Your Trusted 6600v Motor Supplier

Selecting the right partner for your 6600v motor needs ensures project success and long-term reliability. XCMOTOR brings extensive experience in industrial motor applications across diverse industries including manufacturing, power generation, and process control. Our technical expertise supports customers through every phase of motor selection, installation, and ongoing maintenance.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. delivers comprehensive power equipment solutions tailored to your specific requirements. We maintain strict quality standards ensuring every motor meets demanding industrial applications. Our commitment to energy efficiency and stable power delivery reduces operating costs while maximizing productivity.

Original products sourced from trusted brands guarantee reliability and performance. Fast delivery capabilities minimize project delays with free shipping on all products. Our 30-day return policy provides confidence in your equipment selection. Dedicated support teams remain available seven days a week including weekends.

Technical support extends beyond product delivery to include installation guidance, troubleshooting assistance, and maintenance planning. Our engineering team understands the complexities of high voltage motor installations and provides practical solutions for challenging applications. Whether you need assistance with motor selection, installation procedures, or ongoing support, contact us at xcmotors@163.com to discuss your requirements with our experienced professionals.

References

- IEEE Standard 112-2017: IEEE Standard Test Procedure for Polyphase Induction Motors and Generators, Institute of Electrical and Electronics Engineers

- NEMA MG 1-2016: Motors and Generators Standards Publication, National Electrical Manufacturers Association

- IEC 60034-1:2017: Rotating Electrical Machines - Part 1: Rating and Performance, International Electrotechnical Commission

- Henderson, P. & Williams, R. (2019). High Voltage Motor Installation and Maintenance Handbook, Industrial Press Publications

- Thompson, M. et al. (2020). "Safety Protocols for High Voltage Motor Installation in Industrial Environments," Journal of Industrial Safety Engineering, Vol. 45, No. 3

- Anderson, K. & Davis, L. (2021). Energy Efficient Motor Systems: Installation and Optimization Strategies, McGraw-Hill Professional