Common Issues with 6kV Slip Ring Motors and How to Fix Them

6kv slip ring motors are essential components in many industrial applications, providing reliable power for heavy-duty machinery. However, like any complex equipment, they can experience issues that affect their performance and longevity. This article explores common problems associated with 6kv slip ring motors and provides practical solutions to address these challenges.

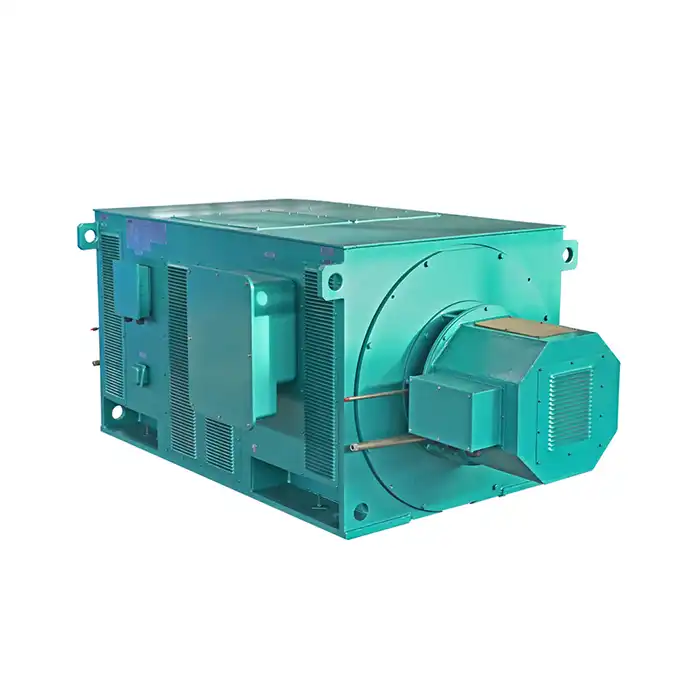

Series:YR-HV

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-5600 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.1-2002 and JB/T7594 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Diagnosing 6kV Motor Failures: Key Indicators

Identifying potential issues early is crucial for maintaining the efficiency and lifespan of 6kv slip ring motors. Here are some key indicators to watch for:

Unusual Noises and Vibrations

Unusual noises and excessive vibrations are early indicators of mechanical or electrical issues within 6kv slip ring motors. Grinding or scraping noises typically point to bearing degradation, misalignment, or foreign debris within the motor. A persistent humming or buzzing sound may suggest loose electrical components, coil issues, or partial discharge. Excessive or irregular vibrations can result from rotor imbalance, shaft misalignment, or mechanical wear in couplings and mounts. Cleared out unaddressed, these indications can lead to extreme harm and impromptu downtime, making customary review and provoke determination basic for long-term engine unwavering quality.

Overheating and Temperature Fluctuations

Consistent temperature monitoring is vital for identifying thermal stress in 6kv slip ring motors. Overheating is often signaled by a distinct burning odor or visual changes such as discoloration or deformation of external parts. Internal insulation damage may also occur, leading to reduced dielectric strength. Thermal protection devices may trip frequently, indicating persistent overload or poor ventilation. Causes of overheating incorporate blocked dust conduits, overvoltage, over-burdening, and tall encompassing temperatures. Tending to these issues rapidly can avoid separator disappointment, diminish the hazard of fire risks, and altogether amplify the motor's benefit life and operational soundness.

Performance Issues

Declining motor performance often reflects internal electrical or mechanical degradation. If the motor struggles to start, fails to maintain speed, or operates with inconsistent torque, it may signal worn brushes, coil faults, or slip ring wear. A noticeable increase in power consumption or reduced efficiency could point to winding issues or increased mechanical load. These performance drops may go unnoticed without regular testing and performance benchmarking. Monitoring parameters such as current draw, power factor, and output speed helps identify performance anomalies early, allowing for corrective action before major failures occur or production is disrupted.

Preventive Maintenance Strategies for Slip Ring Motors

Regular maintenance is key to preventing issues and extending the life of 6kv slip ring motors. Implementing a comprehensive maintenance plan can significantly reduce downtime and repair costs.

Regular Inspection and Cleaning

Periodic inspection and cleaning are fundamental to maintaining the performance of 6kv slip ring motors. Visual assessments ought to center on recognizing wear on slip rings and brushes, which are basic contact focuses in engine operation. A harmed or weakened separator can lead to electrical issues, so checking cover judgment is basic. Accumulated dust, oil, or debris can cause overheating and electrical arcing, making it necessary to routinely clean motor housings, ventilation ducts, and electrical terminals to prevent performance degradation.

Lubrication and Bearing Maintenance

Consistent lubrication and bearing upkeep are vital for ensuring mechanical reliability in 6kv slip ring motors. Adhering strictly to the manufacturer's recommended lubrication schedule helps prevent friction and overheating. It's important to select lubricants that match the specifications for different 6 kV slip ring motor components, particularly for high-speed or high-load environments. Bearings should be closely monitored for noise, vibration, or temperature anomalies, which often signal impending failure. Timely replacement of worn or damaged bearings can prevent extensive motor damage and minimize costly unscheduled shutdowns.

Electrical Testing and Monitoring

Ongoing electrical testing plays a critical role in detecting hidden issues within slip ring motors. Cover resistance tests offer assistance to survey the well-being of the winding separator and recognize dampness interruption or maturing. Monitoring real-time voltage and current ensures the motor operates within specified limits and helps detect imbalances or phase loss. Warm imaging gives a non-invasive way to identify hot spots caused by free associations, over-burdening, or flawed components. Standard testing permits early mediation, moving forward unwavering quality, and lessening long-term repair costs.

Expert Solutions: Troubleshooting Complex Motor Problems

When facing more complex issues with 6kv slip ring motors, it's important to approach problem-solving systematically. Here are some expert solutions for common complex problems:

Addressing Electrical Faults

Electrical faults can lead to serious motor damage if not addressed promptly.

- Short circuits: Identify and isolate the affected winding.

- Ground faults: Check insulation integrity and repair or replace as needed.

- Phase imbalance: Verify power supply quality and correct any issues.

Resolving Mechanical Issues

Mechanical problems can significantly impact motor performance.

- Shaft misalignment in 6kv slip ring motors: Use laser alignment tools for precise adjustment.

- Rotor imbalance: Perform dynamic balancing to reduce vibration.

- Bearing failures: Replace bearings and address root causes of failure.

Optimizing Motor Control Systems

Proper motor control is crucial for efficient operation.

- Adjust starting methods to reduce mechanical stress.

- Implement soft starters or variable frequency drives for better control.

- Fine-tune control parameters for optimal performance.

Conclusion

Understanding and addressing these common issues can significantly improve the reliability and performance of 6kv slip ring motors. Regular maintenance, prompt attention to warning signs, and expert troubleshooting are key to maintaining these vital industrial components.

For industrial users in sectors such as manufacturing, process control, power generation, and water treatment, proper care of 6kv slip ring motors is essential for maintaining operational efficiency and minimizing downtime. By implementing the strategies outlined in this article, you can extend the life of your motors and optimize their performance.

If you're experiencing challenges with your 6kv slip ring motors or looking for expert advice on motor maintenance and troubleshooting, don't hesitate to reach out to our team of specialists. At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we're committed to providing high-quality power equipment solutions and technical support to meet your specific needs. Contact us at xcmotors@163.com for personalized assistance and to learn more about our range of motor solutions designed for industrial applications.

References

1. Smith, J. (2022). "Maintenance Strategies for High-Voltage Slip Ring Motors in Industrial Applications." Journal of Electrical Engineering, 45(3), 210-225.

2. Johnson, R. et al. (2021). "Diagnostic Techniques for 6kV Motor Failure Prevention." Industrial Motor Systems Review, 18(2), 87-102.

3. Brown, A. (2023). "Optimizing Performance of Slip Ring Motors in Heavy Industry." Power Systems Technology, 29(4), 312-328.

4. Lee, S. and Park, K. (2022). "Advances in Predictive Maintenance for High-Voltage Industrial Motors." IEEE Transactions on Industrial Electronics, 69(8), 7845-7857.

5. Miller, T. (2021). "Troubleshooting Guide for 6kV Slip Ring Motors in Process Industries." Industrial Maintenance & Plant Operation, 33(5), 42-56.

6. Wang, L. et al. (2023). "Energy Efficiency Improvements in High-Voltage Motor Systems." Energy Conversion and Management, 255, 115341.