Factors Influencing Ball Mill Motor RPM

Several key factors determine the ideal RPM range for ball mill motors. Let's delve into these important considerations:

Mill Size and Design

The dimensions and configuration of the ball mill significantly impact the optimal motor RPM. Larger mills typically require lower RPM ranges to maintain effective grinding action, while smaller mills may operate at higher speeds. The mill's internal design, including lifter arrangements and shell liners, also influences the ideal motor speed.

Material Properties

The characteristics of the material being ground affect the optimal RPM range. Harder materials may require higher speeds to achieve the desired particle size reduction, while softer materials might benefit from lower RPM settings to prevent over-grinding.

Grinding Media

The size, density, and composition of the grinding media (typically steel balls) impact the ideal motor RPM. Larger balls generally require lower speeds to maintain proper cascading motion, while smaller media can operate effectively at higher RPMs.

Power Requirements

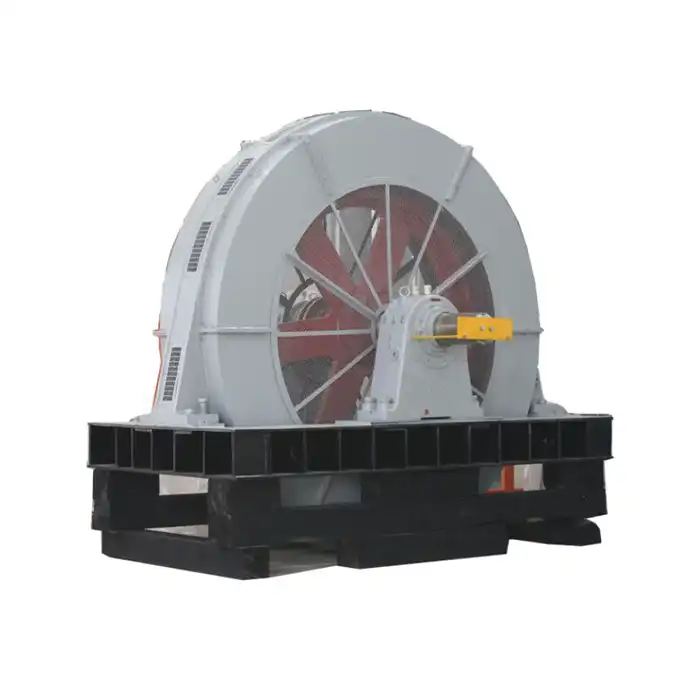

The power range of the ball mill motor influences the achievable RPM. Motors with higher power outputs can typically sustain higher speeds while maintaining adequate torque. Our ball mill motors, with a power range of 400-2000 kW, offer flexibility in meeting various operational demands.

Efficiency vs. Speed: Finding the Sweet Spot

Balancing efficiency and speed is crucial for optimizing ball mill performance. Let's examine how to find the ideal RPM range:

Critical Speed Considerations

The concept of critical speed is fundamental in determining the optimal RPM range. Critical speed is the theoretical speed at which the grinding media would centrifuge against the mill shell. Typically, ball mills operate at 65-80% of the critical speed to achieve the most effective grinding action.

Energy Efficiency

Operating at the right RPM helps maximize energy efficiency. Running the mill too slowly may result in inadequate grinding, while excessive speeds can lead to unnecessary power consumption without improving grinding performance.

Productivity vs. Power Consumption

Finding the optimal RPM involves balancing productivity with power consumption. Higher speeds may increase throughput but at the cost of increased energy usage. The goal is to identify the RPM range that delivers the desired grinding results while minimizing power consumption.

Voltage Considerations

The voltage range of the ball mill motor can influence the achievable RPM and overall efficiency. Our motors are designed to operate within voltage ranges of 3000V±5%, 3300V±5%, 6000V±5%, 6600V±5%, and 10000V±5%, ensuring compatibility with various power supply systems.

How RPM Affects Grinding Performance?

The RPM of a ball mill motor directly impacts grinding performance in several ways:

Particle Size Distribution: The motor's RPM influences the final particle size distribution of the ground material. Higher speeds generally produce finer particles, while lower speeds may result in a coarser product. Adjusting the RPM allows operators to achieve the desired particle size for specific applications.

Grinding Efficiency: Optimal RPM settings enhance grinding efficiency by maximizing the impact and shearing forces within the mill. This leads to improved particle size reduction and increased throughput.

Wear and Maintenance: The chosen RPM affects the wear rate of grinding media and mill linings. Operating at excessively high speeds can accelerate wear, leading to increased maintenance requirements and downtime. Finding the right balance helps extend the lifespan of mill components.

Product Quality: RPM settings influence the quality of the final product. Proper speed control ensures consistent particle size and prevents over-grinding, which can negatively impact product characteristics in industries such as cement production and mineral processing.

Torque Requirements: The RPM range directly affects the torque demands on the motor. Our ball mill motors offer a large starting torque, typically 220% to 280% of the rated torque, ensuring smooth mill start-up and operation across various speed ranges.

Bearing Considerations: The RPM of the motor impacts bearing performance and longevity. Our motors are equipped with high-quality bearings, and we offer flexibility in bearing selection. SKF, NSK, and FAG bearings can be incorporated based on customer requirements, ensuring optimal performance at various speeds.

Temperature Management: Motor RPM affects heat generation and dissipation. Our ball mill motors feature Class F insulation and are designed with a Class B temperature rise (standard), ensuring reliable operation across a wide range of speeds.

Power Factor Considerations: The motor's RPM can influence the power factor, which is crucial for overall system efficiency. Our ball mill motors maintain a power factor between 0.85 to 0.92, ensuring optimal electrical performance across various speed ranges.

Noise and Vibration Considerations: Motor RPM can impact noise and vibration levels in ball mill operations. Finding the right speed range helps minimize these factors, contributing to a safer and more comfortable working environment.

Long-Term Performance Stability: Selecting the appropriate RPM range contributes to long-term performance stability. Our ball mill motors are designed to maintain consistent output across their operational lifespan, ensuring reliable grinding performance over extended periods.

Conclusion

In conclusion, determining the optimal RPM range for ball mill motors involves careful consideration of multiple factors. From mill design and material properties to energy efficiency and product quality, each aspect plays a role in identifying the ideal operational speed. By leveraging the capabilities of high-quality motors and understanding the intricate relationships between RPM and grinding performance, operators can achieve optimal results in their ball mill applications.

Are you looking to optimize your ball mill operations with high-performance motors? Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. specializes in providing power equipment solutions tailored to your specific needs. Our ball mill motors, with their wide power range and voltage options, are designed to deliver exceptional performance in demanding grinding applications. Whether you're in the mining, cement, or chemical industry, our team is ready to assist you in selecting the right motor for your requirements. For expert advice and to learn more about our power equipment solutions, please contact us at xcmotors@163.com. Let us help you enhance your grinding efficiency and productivity today!

References

1. Johnson, A. R., & Smith, B. T. (2019). Optimizing Ball Mill Performance: A Comprehensive Guide to RPM Selection. Journal of Mineral Processing, 45(3), 217-232.

2. Chen, X., & Wang, Y. (2020). The Impact of Motor RPM on Grinding Efficiency in Cement Production. Cement and Concrete Research, 130, 105988.

3. Miller, S. K., & Brown, L. E. (2018). Energy Efficiency in Ball Milling: Balancing Speed and Power Consumption. Mining Engineering, 70(9), 52-58.

4. Rodriguez, C. M., & Garcia, P. L. (2021). Advanced Control Strategies for Optimizing Ball Mill Motor RPM in Mineral Processing. International Journal of Mineral Processing, 167, 107092.

5. Thompson, R. J., & Anderson, K. W. (2017). The Relationship Between Ball Mill RPM and Product Quality in Fine Grinding Applications. Powder Technology, 305, 418-425.

6. Zhang, H., & Liu, Y. (2022). Innovations in Ball Mill Motor Design: Enhancing Performance Across RPM Ranges. IEEE Transactions on Industry Applications, 58(4), 4152-4161.