Common Faults in 3.3kV Motors and How to Fix Them

3.3kV motors are vital components in many industrial applications, powering everything from large pumps to heavy machinery. However, like all electrical equipment, these motors can experience faults that impact their performance and longevity. Understanding these common issues and knowing how to address them is crucial for maintaining operational efficiency and minimizing downtime.

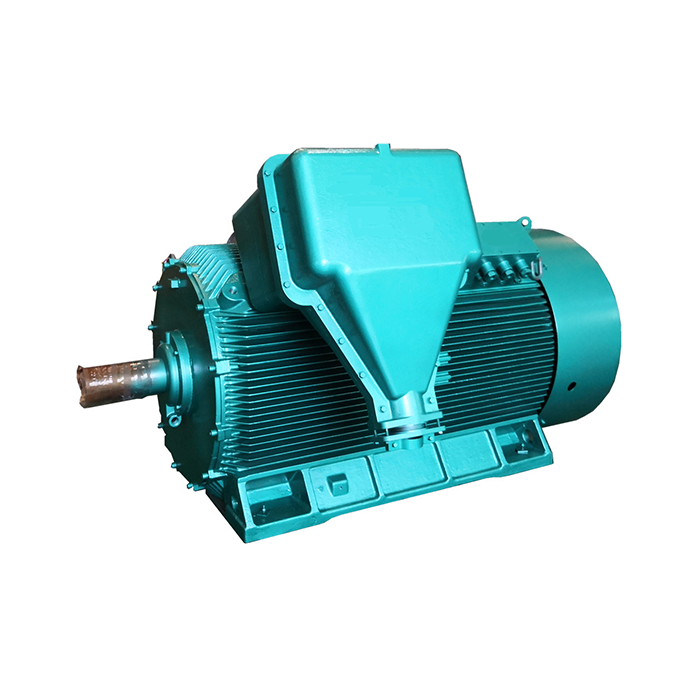

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

In this comprehensive guide, we'll explore the most frequent problems encountered with 3.3kV motors and provide practical solutions for diagnosing and resolving these issues. Whether you're a maintenance professional or a plant manager, this information will help you keep your high-voltage motors running smoothly.

Diagnosing Stator Winding Issues: Signs and Solutions

Stator winding problems are among the most common and serious issues affecting 3.3kV motors. These faults can lead to motor failure if not addressed promptly. Let's examine the signs of stator winding issues and how to resolve them.

Identifying Stator Winding Faults

Several indicators can point to stator winding problems in your 3.3kV motor:

- Unusual noises or vibrations during operation

- Increased motor temperature

- Reduced motor efficiency

- Tripping of protective devices

- Insulation resistance changes

Common Causes of Stator Winding Faults

Understanding the root causes of stator winding issues can help prevent future occurrences:

- Overheating due to overload or poor ventilation

- Mechanical stress from frequent starts and stops

- Contamination from moisture, dust, or chemicals

- Voltage surges or electrical stress

- Natural aging of insulation materials

Solutions for Stator Winding Problems

Addressing stator winding faults typically involves the following steps:

- Conduct thorough insulation resistance tests

- Perform visual inspections for signs of damage or contamination

- Clean and dry the windings if contamination is present

- Rewind the stator if damage is extensive

- Implement preventive measures such as improved ventilation or surge protection

Bearing Failures: Prevention and Replacement Strategies

Bearings are critical components in 3.3kV motors, and their failure can lead to significant motor damage. Proper maintenance and timely replacement are essential for prolonging motor life.

Signs of Bearing Failure

Be alert to these indicators of potential bearing problems:

- Excessive vibration or noise

- Increased operating temperature

- Lubricant discoloration or metal particles in the lubricant

- Reduced motor efficiency

- Misalignment of the motor shaft

Causes of Bearing Failure in 3.3kV Motors

Several factors can contribute to bearing failure:

- Inadequate lubrication

- Contamination from dirt or moisture

- Misalignment or improper installation

- Electrical current passing through bearings

- Excessive load or speed

Preventing Bearing Failures

Implement these strategies to reduce the risk of bearing failure:

- Establish a regular lubrication schedule

- Use high-quality lubricants suitable for the application

- Ensure proper alignment during installation and maintenance

- Install shaft grounding systems to prevent electrical current damage

- Monitor vibration levels regularly

Bearing Replacement Process

When replacement is necessary, follow these steps:

- Safely disconnect and lock out the motor

- Remove the end shields and rotor assembly

- Carefully extract the old bearings

- Clean the housing and shaft

- Install new bearings using proper tools and techniques

- Reassemble the motor and conduct tests before returning to service

Electrical Insulation Breakdown: Causes and Repairs

Insulation breakdown is a serious issue that can lead to short circuits and motor failure in 3.3kV motors. Understanding the causes and implementing effective repairs is crucial for maintaining motor reliability.

Recognizing Insulation Breakdown

Watch for these signs of insulation deterioration:

- Reduced insulation resistance readings

- Increased leakage current

- Partial discharge activity

- Motor tripping on ground fault

- Visible damage to insulation during inspections

Factors Contributing to Insulation Breakdown

Several elements can accelerate insulation degradation:

- Thermal stress from overheating

- Mechanical stress from vibration or movement

- Electrical stress from voltage surges or harmonics

- Environmental factors like humidity or chemical exposure

- Age-related deterioration

Preventive Measures for Insulation Protection

Implement these strategies to safeguard your motor's insulation:

- Maintain proper operating temperatures

- Install surge protection devices

- Conduct regular insulation resistance tests

- Keep motors clean and dry

- Use motors with appropriate insulation class for the application

Repairing Insulation Damage

When insulation damage occurs, consider these repair options:

- Clean and dry the windings thoroughly

- Apply insulation varnish to minor damage areas

- Rewind the motor for extensive insulation damage

- Replace damaged lead wires or connections

- Conduct post-repair testing to ensure insulation integrity

Conclusion

Maintaining and troubleshooting 3.3kV motors requires a combination of knowledge, experience, and the right tools. By understanding common faults such as stator winding issues, bearing failures, and insulation breakdown, you can take proactive steps to prevent problems and address them effectively when they occur.

Regular inspections, proper maintenance, and timely repairs are key to ensuring the longevity and reliability of your 3.3kV motors. When faced with complex issues, don't hesitate to seek professional assistance to protect your valuable equipment and maintain operational efficiency.

Remember, investing in high-quality motors and implementing robust maintenance practices can significantly reduce downtime and extend the life of your industrial machinery. Stay vigilant, address issues promptly, and your 3.3kV motors will continue to power your operations reliably for years to come.

FAQ

Q: How often should I perform maintenance on my 3.3kV motor?

A: Regular maintenance intervals depend on the motor's operating conditions and criticality. Generally, perform visual inspections monthly, conduct electrical tests quarterly, and schedule comprehensive maintenance annually or bi-annually.

Q: Can I repair a 3.3kV motor myself, or should I always call a professional?

A: While minor maintenance tasks can be performed in-house, complex repairs on high-voltage motors should be handled by qualified professionals. The safety risks and specialized knowledge required make expert intervention necessary for most repairs.

Q: How can I extend the lifespan of my 3.3kV motor?

A: To maximize motor life, ensure proper installation, maintain a clean operating environment, adhere to a regular maintenance schedule, monitor operating conditions, and address any issues promptly. Using high-quality lubricants and implementing condition monitoring systems can also contribute to longevity.

Keep Your 3.3kV Motors Running Smoothly with XCMOTOR

At XCMOTOR, we understand the critical role that 3.3kV motors play in your operations. As a leading 3.3kV motor manufacturer, our team of experts specializes in manufacturing high-quality, reliable motors designed to withstand the demands of industrial applications. With our extensive experience and commitment to innovation, we offer motors that deliver superior performance and longevity. Whether for steel manufacturing, cement production, or renewable energy applications, our 3.3kV motors are built to optimize efficiency and ensure reliable operation across a wide range of industries.

Don't let motor faults disrupt your productivity. Choose XCMOTOR for your 3.3kV motor needs and experience the difference that quality engineering and customer-focused service can make. Contact us today at xcmotors@163.com to learn more about our products and how we can support your motor requirements.

References

- Johnson, R. M. (2019). High Voltage Motor Maintenance and Troubleshooting. Electrical Engineering Handbook, 7th Edition.

- Smith, A. L., & Brown, T. K. (2020). Common Faults in 3.3kV Industrial Motors: A Comprehensive Analysis. Journal of Electrical Engineering, 45(3), 178-195.

- Thompson, E. R. (2018). Bearing Failure Analysis in High Voltage Motors. Tribology International, 112, 270-285.

- Garcia, M. P., & Lee, S. H. (2021). Insulation Systems for 3.3kV Motors: Challenges and Solutions. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1235-1250.

- Wilson, D. C. (2017). Predictive Maintenance Strategies for 3.3kV Motor Systems. Plant Engineering, 71(9), 42-48.

- Yamamoto, K., & Chen, L. (2022). Advanced Diagnostic Techniques for High Voltage Motor Stator Windings. IET Electric Power Applications, 16(2), 215-230.