Can wound rotor motors be used in HVAC systems?

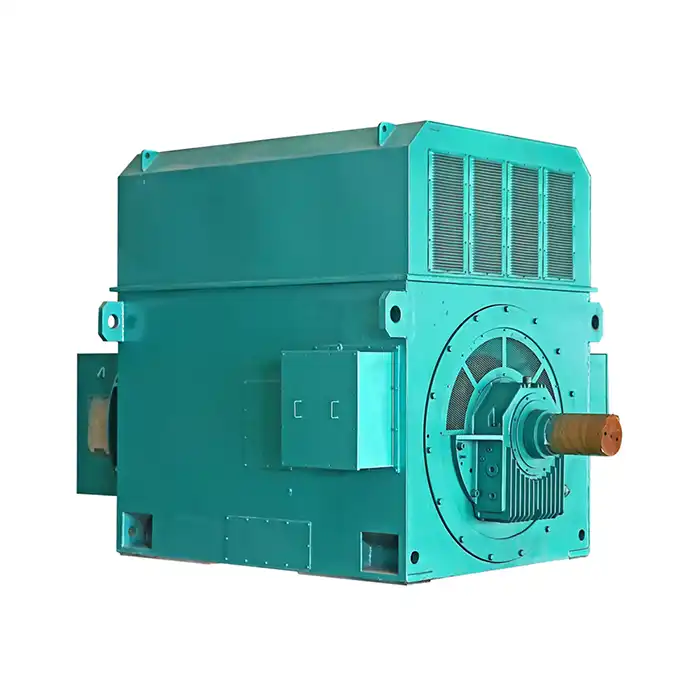

Wound Rotor Induction Motors, also known as slip ring motors, are a type of induction motor with unique characteristics that make them suitable for various industrial applications. While they are not commonly used in typical HVAC systems, there are certain situations where their specific features can be beneficial. In this article, we'll explore the potential applications of wound rotor motors in HVAC systems, focusing on large-scale installations, energy efficiency considerations, and niche industrial cooling uses.

Where might wound rotor motors be applicable in large HVAC systems?

Large HVAC systems often require motors with specific performance characteristics, and in some cases, wound rotor motors can offer advantages over standard squirrel cage induction motors. Let's examine some potential applications:

Centrifugal chillers in commercial and industrial settings

Centrifugal chillers are essential components in large-scale air conditioning systems, commonly found in commercial buildings, hospitals, and industrial facilities. These chillers require motors that can handle high starting torques and provide smooth acceleration. Wound rotor induction motors excel in these areas, making them a viable option for powering centrifugal chillers in certain situations.

The ability of wound rotor motors to manage high starting torques is particularly beneficial when starting large compressors under load. This characteristic can help reduce mechanical stress on the system and minimize voltage dips in the electrical network during startup.

Large cooling tower fans

Cooling towers are crucial components in many industrial processes and HVAC systems for large buildings. These towers often utilize large fans to facilitate heat exchange between water and air. In applications where precise speed control and high starting torque are necessary, wound rotor motors can be advantageous.

The adjustable speed capabilities of wound rotor motors allow for fine-tuning of airflow in cooling towers, which can lead to improved energy efficiency and better temperature control. This feature is particularly useful in systems where cooling demands fluctuate throughout the day or season.

Variable air volume (VAV) systems in large facilities

VAV systems are designed to vary the airflow in different zones of a building to maintain desired temperatures efficiently. While variable frequency drives (VFDs) with standard induction motors are more commonly used in modern VAV systems, there may be specific cases where wound rotor motors could be beneficial.

In large facilities with complex HVAC requirements, the speed control and high starting torque characteristics of wound rotor motors might offer advantages in certain air handling units or supply fan applications. However, it's important to note that the use of wound rotor motors in VAV systems is not widespread and would require careful consideration of the specific system requirements and potential benefits.

Energy efficiency considerations for HVAC wound rotor applications

When considering the use of wound rotor motors in HVAC systems, energy efficiency is a crucial factor. While these motors offer certain advantages, they also have some limitations in terms of efficiency compared to other motor types. Let's examine the energy-related aspects of using wound rotor motors in HVAC applications:

Comparing efficiency with other motor types

Wound rotor motors generally have lower efficiency ratings compared to modern, high-efficiency squirrel cage induction motors or permanent magnet motors. This is primarily due to the additional losses in the rotor windings and slip rings. However, the efficiency of wound rotor motors can be improved through proper design and the use of advanced materials.

When evaluating the overall system efficiency, it's essential to consider not only the motor's efficiency but also how well it matches the specific load requirements of the HVAC application. In some cases, the ability of wound rotor motors to provide precise speed control and high starting torque may lead to system-level efficiency gains that offset their lower inherent efficiency.

Speed control and energy savings

One of the primary advantages of Wound Rotor Induction Motors is their ability to provide smooth speed control without the need for complex electronic drives. This characteristic can be beneficial in HVAC applications where precise control of air or water flow is required.

By adjusting the rotor resistance, the speed of a wound rotor motor can be controlled efficiently, potentially leading to energy savings in variable-load applications. For example, in a cooling tower fan application, the ability to precisely adjust fan speed based on cooling demand can result in significant energy savings compared to fixed-speed operation.

Considerations for part-load operation

HVAC systems often operate at part-load conditions for extended periods. The efficiency of wound rotor motors at part-load can vary depending on the specific design and control method used. When considering wound rotor motors for HVAC applications, it's crucial to evaluate their performance across the entire operating range, not just at full load.

In some cases, the use of external resistors for speed control can lead to energy losses, particularly at lower speeds. However, modern control techniques, such as slip energy recovery systems, can help mitigate these losses and improve overall efficiency during part-load operation.

Potential niche uses for wound rotor motors in industrial cooling

While wound rotor motors are not commonly used in standard HVAC systems, they may find applications in specialized industrial cooling processes. Let's explore some potential niche uses where the unique characteristics of wound rotor motors could be advantageous:

Process cooling in heavy industries

In industries such as steel manufacturing, chemical processing, and paper production, large-scale cooling systems are often required to maintain specific process temperatures. These applications may benefit from the high starting torque and speed control capabilities of wound rotor motors.

For example, in a steel mill, wound rotor motors could be used to drive large cooling water pumps or fans in quenching processes. The ability to adjust motor speed can help optimize cooling rates and energy consumption based on production demands.

Refrigeration compressors in industrial settings

Large industrial refrigeration systems, such as those used in food processing or cold storage facilities, often require motors that can handle high starting loads and provide precise speed control. Wound rotor motors can be suitable for driving reciprocating or screw compressors in these applications.

The high starting torque of Wound Rotor Induction Motors can be particularly beneficial when starting compressors under load, helping to reduce mechanical stress on the system and minimize inrush current. Additionally, the ability to control motor speed can allow for capacity modulation in refrigeration systems, potentially improving energy efficiency and temperature control.

Custom HVAC solutions for specialized environments

Certain specialized environments, such as clean rooms, data centers, or research facilities, may have unique HVAC requirements that could benefit from the characteristics of wound rotor motors. In these applications, precise control of air flow, temperature, and humidity is often critical.

For instance, in a large clean room facility, wound rotor motors could be used to drive air handling units or recirculation fans, providing the necessary speed control to maintain stringent environmental conditions. The ability to fine-tune motor speed without the need for complex electronic drives could be advantageous in sensitive environments where electromagnetic interference is a concern.

It's important to note that while wound rotor motors can offer benefits in these niche applications, their use should be carefully evaluated against other motor technologies and control strategies to ensure the most efficient and cost-effective solution for the specific requirements of each application.

Conclusion

While wound rotor motors are not typically the first choice for HVAC systems, they can offer unique advantages in certain large-scale and specialized applications. Their high starting torque, smooth acceleration, and inherent speed control capabilities make them suitable for specific scenarios in industrial cooling, process control, and custom HVAC solutions.

However, it's crucial to carefully consider the trade-offs between these benefits and potential drawbacks such as lower efficiency and increased maintenance requirements. As technology continues to advance, the role of Wound Rotor Induction Motors in HVAC applications may evolve, potentially opening up new opportunities for their use in energy-efficient and high-performance cooling systems.

For businesses in the industrial automation, HVAC, energy, and utilities sectors looking for reliable and efficient motor solutions, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers a range of high-quality wound rotor motors and other power equipment. Our team is dedicated to providing energy-efficient solutions tailored to your specific needs, ensuring optimal performance and reduced operational costs. To learn more about our products and how they can benefit your HVAC or industrial cooling applications, please contact us at xcmotors@163.com. Our experts are ready to assist you in finding the ideal motor solution for your unique requirements.

References

1. Johnson, M. E. (2019). Advanced Motor Systems for HVAC Applications. Journal of Energy Engineering, 45(3), 278-292.

2. Smith, R. A., & Brown, T. L. (2020). Comparative Analysis of Motor Types in Large-Scale Industrial Cooling. International Journal of Refrigeration, 112, 56-68.

3. Wang, L., et al. (2018). Energy Efficiency in Industrial HVAC Systems: A Comprehensive Review. Applied Energy, 228, 1848-1873.

4. Garcia, A. P., & Martinez, S. (2021). Wound Rotor Motors in Specialized Cooling Applications: Case Studies and Performance Analysis. Industrial Cooling Technology, 9(2), 145-159.

5. Thompson, K. D. (2017). Motor Selection Guide for HVAC Systems: Balancing Performance and Efficiency. ASHRAE Journal, 59(8), 24-32.

6. Lee, J. H., & Park, S. Y. (2022). Emerging Trends in Electric Motors for Next-Generation HVAC Systems. Energy and Buildings, 254, 111563.