IP23 Protection: Moisture Resistance Explained

IP23 motors offer a specific level of protection against solid objects and water ingress. To understand their capabilities in wet environments, it's essential to break down the IP rating system and what IP23 specifically means.

Understanding IP Ratings

IP ratings, or Ingress Protection ratings, consist of two digits. The first digit indicates protection against solid objects, while the second digit represents protection against liquids. For IP23 motors:

- The "2" signifies protection against solid objects larger than 12.5mm

- The "3" indicates protection against water spray at angles up to 60° from vertical

Water Resistance of IP23 Motors

IP23 motors can withstand some exposure to water, but their protection is limited. They're designed to handle light water spray, such as rain falling at an angle. However, they're not suitable for environments with heavy water exposure or submersion.

Comparing IP23 to Other Ratings

To put IP23 in perspective, it's helpful to compare it with other common IP ratings:

- IP44: Protected against solid objects over 1mm and water splashing from all directions

- IP55: Protected against dust and low-pressure water jets

- IP67: Dust-tight and protected against temporary immersion

IP23 offers less protection than these higher-rated options, which is important to consider when selecting motors for wet environments.

Wet Environment Applications: Pros and Cons

While IP23 motors have limitations in wet environments, they may still be suitable for certain applications. Let's examine the potential uses and drawbacks of employing IP23 motors in damp conditions.

Suitable Applications for IP23 Motors

IP23 motors can be used in environments where they might encounter light moisture or occasional water spray. Potential applications include:

- Ventilation systems in covered outdoor areas: IP23 motors are ideal for use in ventilation systems located in areas with partial protection from the elements. These motors can handle light moisture or occasional water spray, making them suitable for environments like outdoor shelters, patios, or canopies. They provide reliable performance without compromising the safety of the motor or the efficiency of the system.

- Some industrial equipment in partially sheltered locationsL: In certain industrial settings, equipment may be located in spaces that are not fully enclosed but still provide some protection from the elements. IP23 motors are well-suited for such applications, where the motor may face brief exposure to light rain or moisture. These motors can perform effectively without risk of damage, ensuring continued operation in challenging conditions.

- Machinery in environments with occasional light rain exposure: IP23 motors can also be used in environments where machinery may occasionally be exposed to light rain, such as outdoor production lines or equipment near open windows. The design of these motors ensures that they can withstand occasional splashes and moisture, maintaining operational integrity in settings where full protection from the weather is not always possible.

Limitations in Wet Environments

Despite their ability to handle some moisture, IP23 motors have significant limitations in wet conditions:

- Not suitable for direct exposure to heavy rain or water jets

- Cannot withstand submersion or flooding

- May be damaged by prolonged exposure to high humidity

Risks of Using IP23 Motors in Wet Conditions

Using IP23 motors in environments that exceed their moisture protection capabilities can lead to several issues:

- Electrical short circuits: Exposing IP23 motors to environments with higher levels of moisture or water can lead to electrical short circuits. Moisture can penetrate the motor casing, potentially causing a short between electrical components and leading to system failure or even fires in severe cases.

- Corrosion of internal components: Excess moisture can accelerate the corrosion of internal motor parts, such as bearings and windings. Over time, this can degrade the motor’s performance and cause irreversible damage, ultimately affecting the motor's operational capacity.

- Reduced efficiency and performance: When an IP23 motor is exposed to excessive moisture, the accumulation of water or humidity inside can disrupt the motor’s electrical systems, causing it to operate less efficiently. This leads to a decrease in overall performance and can result in higher energy consumption.

- Shortened motor lifespan: Continual exposure to moisture beyond the motor's protection rating will gradually degrade its components, leading to premature wear and tear. As a result, the motor’s lifespan is significantly shortened, requiring more frequent repairs or replacements.

- Potential safety hazards: In addition to operational issues, excessive moisture exposure can pose serious safety risks. Water ingress can compromise insulation materials, increasing the risk of electrical shock or fires, and creating dangerous working conditions for operators.

Enhancing IP23 Motors for Increased Moisture Protection

While IP23 motors have inherent limitations in wet environments, there are methods to enhance their protection against moisture. These modifications can extend the range of applications where IP23 motors can be safely and effectively used.

Additional Enclosures and Shields

To enhance moisture resistance, external protection can be added to the motor. Weather-resistant covers or canopies provide an effective barrier against direct exposure to the elements, while sealed enclosures with proper ventilation ensure that the motor remains cool and operates efficiently. Additionally, water-deflecting shields or guards can be installed to redirect water away from the motor, further safeguarding it from moisture. These protective measures allow the motor to maintain its performance while minimizing the risk of damage from water exposure.

Sealants and Coatings

Applying specialized sealants or coatings can offer an additional layer of protection against moisture. Moisture-resistant paints or sprays, epoxy coatings for exposed surfaces, and silicone sealants for joints and seams all work to repel water and prevent moisture from entering sensitive areas of the motor. These treatments help enhance the motor's durability and resistance to environmental factors, ensuring reliable performance in damp conditions.

Improved Drainage and Ventilation

Enhancing the motor's ability to shed water and maintain proper airflow can significantly improve its performance in damp conditions:

- Installing drain holes in appropriate locations

- Adding ventilation ports with protective covers

- Implementing forced-air cooling systems

Regular Maintenance and Inspection

Consistent upkeep is crucial for maintaining the integrity of IP23 motors in potentially wet environments:

- Scheduled inspections for signs of water ingress or corrosion

- Prompt repair or replacement of damaged seals or gaskets

- Regular cleaning to prevent buildup of moisture-trapping debris

Considerations for Retrofitting

When enhancing IP23 motors for increased moisture protection, it's important to consider:

- Impact on motor cooling and efficiency

- Potential changes to motor dimensions or mounting requirements

- Compliance with relevant safety standards and regulations

Consulting with motor experts or manufacturers is advisable when planning significant modifications.

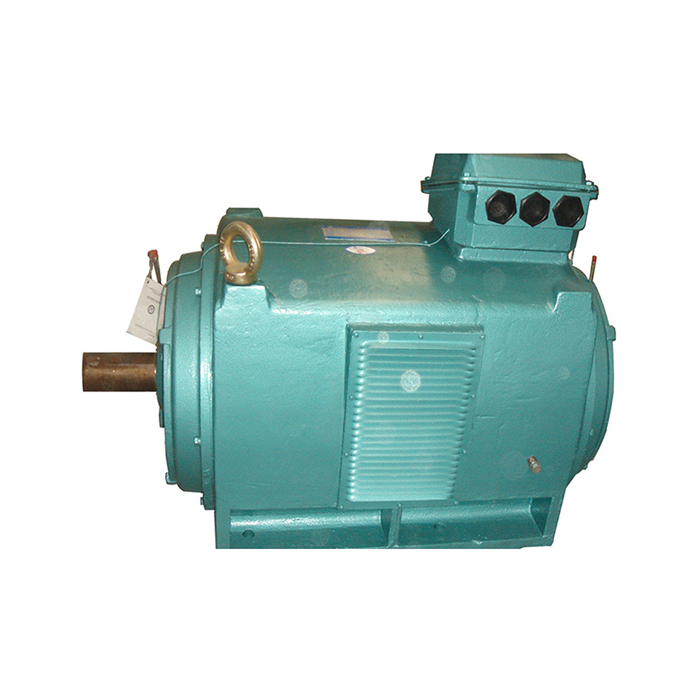

Call to Action: Elevate Your Industrial Performance with XCMOTOR

At XCMOTOR, we understand the challenges of operating motors in diverse environments. Our range of IP23 motors offers reliable performance and efficiency for various industrial applications. With our expertise in motor technology and commitment to customer satisfaction, we can help you find the perfect solution for your specific needs.

Whether you require motors for standard or challenging environments, our team is ready to assist you. We offer customization options and expert advice to ensure optimal performance and longevity of your equipment. Don't let moisture concerns limit your operations. Contact XCMOTOR today at xcmotors@163.com to discover how our motors can drive your success in any environment.