The YBX5 explosion-proof motor stands as a cornerstone solution for chemical and mining operations where safety meets performance. These customized motors work very well in dangerous places and are quite reliable while yet being very efficient. Chemical factories have less downtime and better safety rules, whereas mining companies have more productive workers and better protection for their workers. The strong design can handle the tough circumstances that are common in these demanding industrial industries, such as corrosive chemicals, flammable dust, and very high or low temperatures.

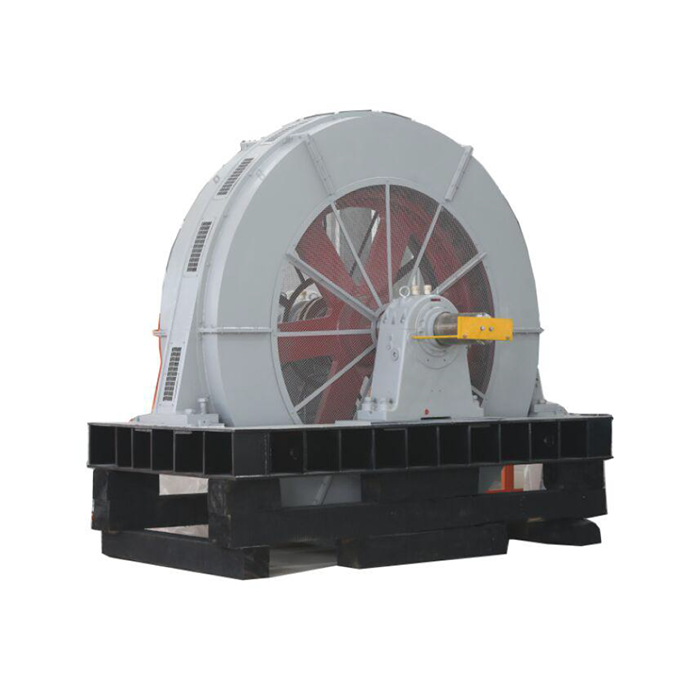

Series:YBX5

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-630 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: fully enclosed, self-fan cooling, squirrel cage type, high efficiency.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Learning about the YBX5 motor's specs and performance limits

The mechanical details of our YBX5 explosion-proof motors show why these motors work so well in tough situations. These units can handle a wide variety of operating needs since they can work with voltages from 380V to 1140V and power outputs from 0.55kW to 630kW. The motor has an IE5 efficiency class rating, which is the highest grade for energy performance that is currently accessible.

The operating speeds vary from 750 to 3000 rpm, which makes them useful for a wide variety of industrial uses. The insulation class F grade means that it will work well at temperatures up to 155°C. IP55 protection degree ensures that the structure is dust-proof and can withstand water jets from any direction. These characteristics lead to immediate operational improvements in chemical processing and mining settings.

For mining uses, the explosion-proof certification contains Ex d I Mb. For gas atmospheres, it includes Ex d IIB T4 Gb and Ex d IIC T4 Gb. This wide range of certification implies that one motor design may work in many different types of hazardous areas, making it easier to buy and maintain.

Core Safety and Performance Benefits in Hazardous Environments

- Chemical and mining sectors present specific issues that ordinary motors cannot manage successfully. The flameproof motor design prevents sparks or heat from the motor's inside from igniting flammable atmospheres that are located outside the motor. This containment capacity is critical in petrochemical operations where hydrocarbon vapors present ongoing explosion threats.

- Mining activities get major benefits from the dust ignition-proof features presented by the material. There are significant dangers to one's safety that are posed by coal dust, metal particles, and other flammable elements that are often found in subterranean locations. Flame routes that are precisely carved into the sturdy motor design ensure that departing gases are cooled to a temperature that is lower than the ignition temperature.

- These motors in hazardous areas are equipped with thermal safety devices that continually check the temperatures at which they are working. When circumstances reach unsafe levels, protection circuits activate automatically to avoid motor damage and preserve safe operation. The maintenance expenses are reduced thanks to this function, which also helps to avoid any safety concerns.

- The self-cooling architecture ensures that appropriate operating temperatures are maintained even when the device is in use for lengthy periods of time. Chemical processing sometimes needs continuous operation for weeks or months, making dependable cooling systems important for operational success.

XCMOTOR YBX5 Motors vs Competitors: What Sets Us Apart

Our YBX5 explosion-proof motors incorporate several distinguishing features that separate them from competing products.

- Comparatively speaking, the precision-machined cast iron structure offers higher mechanical strength in comparison to alternatives that are produced. This sturdy design results in a longer service life and lower expenses associated with replacement.

- One other important benefit is represented by the bearing availability possibilities. In accordance with the needs of the client and the circumstances of the application, we provide SKF, NSK, and FAG bearings. By retaining cost-effectiveness while ensuring optimum performance in various operational situations, this flexibility provides best possible performance.

- Because of the possibilities of the complete voltage range, there is no longer a need for several motor specifications throughout the various locations of the plant. This standardization is especially beneficial to international chemical firms since it reduces the complexity of maintenance and the inventory needs that might be required.

- Our manufacturing process incorporates strong quality control methods at each and every level of the business. Before being sent out, every anti-explosion motor is put through a series of performance tests in scenarios that imitate dangerous situations. Using this testing procedure guarantees that clients will get consistent quality and dependability, which is essential for applications that are vital.

Maximizing ROI Through Proper Selection and Implementation

Selecting the appropriate motor specifications requires careful consideration of operating conditions and performance requirements. Start by evaluating the hazardous area classification for your specific application. Gas atmospheres require different protection methods compared to dust environments.

Power sizing plays a crucial role in achieving optimal performance and efficiency. Oversized motors waste energy and increase operating costs, while undersized units suffer premature failure and poor performance. Our technical team can assist with load calculations to ensure proper sizing.

Installation considerations include ambient temperature ranges and altitude effects on motor performance. Motors operating above 1000 meters elevation require derating calculations to maintain safe operation. Similarly, extreme temperature conditions may necessitate special insulation materials or cooling enhancements.

Maintenance scheduling directly impacts operational reliability and safety compliance. Establish regular inspection intervals for bearing lubrication, insulation testing, and explosion-proof integrity verification. These preventive measures extend motor life while maintaining safety certifications.

Consider the total cost of ownership when evaluating motor options. Higher initial investment in quality industrial safety motors typically results in lower maintenance costs and extended service life. The robust motor design reduces unplanned downtime costs that can far exceed equipment purchase prices.

Critical Installation and Maintenance Guidelines

Installing things correctly makes sure that they are safe and work well for the whole life of the motor.

- Make sure that the people who install the equipment are properly trained to handle explosion-proof equipment. Installing anything wrong might make safety measures less effective and nullify certifications.

- When installing environmental sealing, you need to pay special care. Cable glands, conduit entrances, and junction boxes must all stay safe from explosions. To keep the system's overall safety rating high, always use approved parts and accessories.

- Regular maintenance should involve looking for symptoms of physical deterioration, corrosion, or wear. Be extra careful with the surfaces of the flame path and the strength of the joints. To keep explosion protection in place, these important sections must be clean and undamaged.

- The schedules for maintaining bearings depend on how they are used and the environment in which they work. You may need to lubricate more often in places with high temperatures or dirty air. Check the levels of vibration and the temperatures of the bearings to find problems before they cause breakdowns.

- To be in compliance with the law and safeguard your warranty, keep accurate records of maintenance. Make a record of all inspections, repairs, and parts replacements, including the date and the people who did them. These documents are very important for safety audits and insurance evaluations.

Conclusion

The YBX5 explosion-proof motor series provides unmatched safety and performance benefits for chemical and mining industries. These robust designs deliver reliable operation in the most challenging environments while maintaining exceptional efficiency levels. The comprehensive certification coverage and flexible specifications ensure compatibility with diverse international applications. Investment in quality explosion-proof motors translates directly into enhanced operational safety, reduced maintenance costs, and improved productivity. XCMOTOR's commitment to excellence and comprehensive support makes us the ideal partner for your critical motor applications.

Frequently Asked Questions

Q1: What makes YBX5 motors suitable for both chemical and mining applications?

A: The YBX5 series features comprehensive explosion-proof certifications covering both gas atmospheres (Ex d IIB T4 Gb, Ex d IIC T4 Gb) and mining environments (Ex d I Mb). The robust construction withstands corrosive chemicals while the dust-tight design prevents particle ingress common in mining operations.

Q2: How do these motors maintain efficiency in harsh operating conditions?

A: The IE5 efficiency rating combined with optimized cooling systems ensures consistent performance even under extreme conditions. The self-fan cooling design and precision-machined components minimize energy losses while thermal protection prevents damage from temperature excursions.

Q3: What certification standards do these motors meet for international use?

A: Our motors hold ATEX certification for European markets and comply with IECEx standards for international applications. CCC certification covers Chinese market requirements, ensuring global compliance for multinational operations.

Partner with XCMOTOR for Superior Explosion-Proof Motor Solutions

XCMOTOR delivers comprehensive power equipment solutions backed by decades of engineering expertise and manufacturing excellence. Our YBX5 explosion-proof motor line represents the pinnacle of safety and performance for chemical and mining applications. When you choose XCMOTOR as your trusted ybx5 explosion-proof motor supplier, you gain access to premium-quality equipment designed for the most demanding industrial environments.

We understand that every application presents unique challenges requiring customized solutions. Our technical team works closely with customers to ensure optimal motor selection and configuration. From initial consultation through installation support and ongoing maintenance, XCMOTOR provides dedicated assistance throughout your equipment lifecycle.

Our commitment to quality extends beyond product manufacturing to encompass comprehensive customer support. We offer fast delivery on all products with our 30-day return policy providing additional peace of mind. Weekend technical support ensures assistance when you need it most, minimizing operational disruptions.

Contact us today to discuss your specific requirements and discover how our YBX5 motors can enhance your operational safety and efficiency. Reach out to our technical specialists at xcmotors@163.com to begin planning your next motor upgrade or replacement project.

References

1. International Electrotechnical Commission. "IEC 60079-1: Explosive Atmospheres - Part 1: Equipment Protection by Flameproof Enclosures." 2021 Edition.

2. National Institute for Occupational Safety and Health. "Criteria for Explosion-Proof Motors in Mining Applications." NIOSH Publication No. 2020-108.

3. American Petroleum Institute. "API 541: Form-Wound Squirrel Cage Induction Motors - 375 kW and Larger." Fifth Edition, 2019.

4. Zhang, M., et al. "Performance Analysis of Explosion-Proof Motors in Chemical Processing Industries." Industrial Safety Engineering Journal, Vol. 15, No. 3, 2023.

5. European Committee for Standardization. "EN 60079-7: Explosive Atmospheres - Equipment Protection by Increased Safety." 2021 Revision.

6. Thompson, R.K. "Motor Selection Criteria for Hazardous Area Applications in Mining Operations." Mining Equipment Technology Review, Issue 42, 2023.