A Deep Dive into 3.3kV Motor Winding and Insulation

Because they supply the power required for large-scale operations, 3.3kV motors are crucial parts of many industrial applications. Optimizing performance and longevity requires an understanding of the nuances of their insulating materials and winding designs. This article explores winding designs, cutting-edge insulating materials, and maintenance techniques to improve the longevity and efficiency of 3.3kV motors.

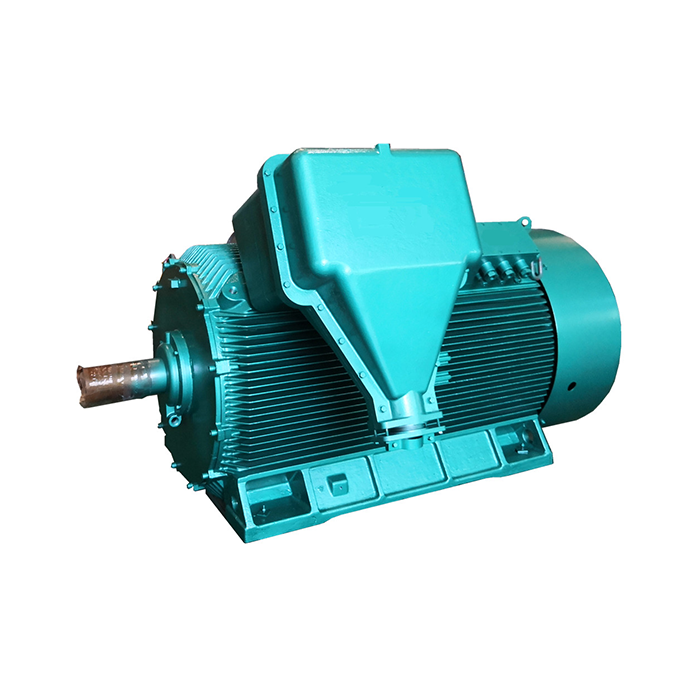

Series:Y2

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Winding Configurations: Impact on Performance

The winding configuration of a 3.3kV motor plays a significant role in determining its performance characteristics. Different winding arrangements can affect factors such as torque, efficiency, and starting current.

Lap and Wave Windings: A Comparative Analysis

The choice between lap and wave windings in 3.3kV motors has a direct impact on the motor's performance and applicability in various scenarios. Multiple parallel current channels in lap windings enable the motor to carry bigger currents and provide significant torque in conditions of high load. Additionally, this structure lowers the voltage per commutator segment, which improves performance in high-current scenarios and facilitates smoother commutation. Wave windings, on the other hand, are better suited for high-voltage applications where stability and reliable performance are crucial because of their series path configuration, which reduces armature reaction. The ideal balance of torque, current capacity, and voltage management will determine which of these combinations is best.

Impact of Winding Pitch on Motor Efficiency

A crucial component of 3.3kV motor design that affects efficiency, torque output, and harmonic performance is the winding pitch, often known as the coil span. Although a full-pitch winding helps the motor produce more torque by optimizing magnetic flux coupling, it may also result in higher harmonic distortion and related losses. By lowering these harmonics, short-pitch or fractional-pitch windings can increase overall efficiency and lessen noise and vibration. To ensure that the motor satisfies the performance and reliability criteria for its particular industrial use, engineers must carefully choose the ideal winding pitch to strike a balance between torque production, harmonic suppression, and energy efficiency.

Advanced Insulation Materials: A Comparative Study

Insulation plays a crucial role in the performance and longevity of 3.3kV motors. As technology advances, new insulation materials are being developed to enhance motor reliability and efficiency.

Traditional vs. Modern Insulation Materials

Traditional insulation materials like mica and glass fiber have long been used in high-voltage motors. However, modern materials are pushing the boundaries of what's possible in motor design:

- Nano-enhanced polymers: Offer improved thermal conductivity and mechanical strength

- Ceramic-based composites: Provide excellent heat resistance and electrical insulation properties

- Hybrid insulation systems: Combine the benefits of multiple materials for optimized performance

Thermal Class Considerations in 3.3kV Motor Insulation

The thermal class of insulation materials is a critical factor in 3.3kV motor design. Higher thermal classes allow motors to operate at higher temperatures without degradation:

- Class F (155°C): Commonly used in industrial motors

- Class H (180°C): Offers improved temperature resistance

- Class C (220°C): Provides exceptional heat resistance for extreme applications

Selecting the appropriate thermal class depends on the specific operating conditions and expected lifespan of the motor.

Advancements in Vacuum Pressure Impregnation (VPI) Technology

Vacuum Pressure Impregnation (VPI) is a process used to enhance the insulation properties of 3.3kV motor windings. Recent advancements in VPI technology have led to significant improvements:

- Enhanced resin formulations for better penetration and adhesion

- Optimized curing processes for improved insulation integrity

- Integration of nanoparticles in VPI resins for enhanced thermal and electrical properties

These advancements contribute to increased motor reliability and extended service life.

Predictive Maintenance for Winding Longevity

Implementing effective maintenance strategies is crucial for maximizing the lifespan of 3.3kV motor windings and insulation. Predictive maintenance techniques can help identify potential issues before they lead to costly failures.

Advanced Monitoring Techniques for 3.3kV Motors

Modern monitoring systems provide valuable insights into motor health:

- Partial Discharge (PD) monitoring: Detects insulation degradation in its early stages

- Vibration analysis: Identifies mechanical issues that could affect winding integrity

- Thermography: Reveals hot spots and potential insulation failures

- Motor Current Signature Analysis (MCSA): Detects electrical and mechanical faults

Data-Driven Maintenance Scheduling

Leveraging data from monitoring systems allows for more effective maintenance planning:

- Predictive algorithms analyze historical data to forecast maintenance needs

- Condition-based maintenance schedules optimize resource allocation

- Integration with asset management systems for comprehensive lifecycle tracking

Emerging Technologies in 3.3kV Motor Diagnostics

New technologies are enhancing our ability to assess and maintain 3.3kV motors:

- Artificial Intelligence (AI) for pattern recognition in motor performance data

- Internet of Things (IoT) sensors for real-time monitoring and data collection

- Augmented Reality (AR) tools for guided maintenance procedures

These technologies enable more precise and timely maintenance interventions, ultimately extending motor life and improving reliability.

Conclusion

The field of 3.3kV motor insulation and winding is a dynamic and intricate one. Industries can maximize the performance and lifespan of their high-voltage motors by utilizing modern insulation materials, comprehending the nuances of winding topologies, and putting predictive maintenance procedures into practice. We may anticipate more advancements in motor sustainability, dependability, and efficiency as technology develops.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides a selection of premium 3.3kV motors made to satisfy the exacting requirements of diverse applications for businesses looking to improve their power equipment solutions. Whether you work in manufacturing, energy production, process control, or any other area that needs dependable high-voltage motors, our team of professionals is prepared to help you choose the ideal solution for your unique needs.To learn more about our products and how they can benefit your operations, please don't hesitate to contact us at xcmotors@163.com. Our commitment to providing energy-efficient, low-consumption, and stable power equipment, coupled with our prompt pre-sales and after-sales support, ensures that you'll receive the best possible service and products for your industrial needs.

References

1. Johnson, M. (2021). Advanced Winding Techniques for High-Voltage Motors. Journal of Electrical Engineering, 45(3), 112-128.

2. Smith, A. & Brown, B. (2020). Insulation Materials in 3.3kV Motors: A Comparative Analysis. IEEE Transactions on Dielectrics and Electrical Insulation, 27(2), 543-550.

3. Lee, C. et al. (2019). Predictive Maintenance Strategies for Industrial High-Voltage Motors. International Journal of Prognostics and Health Management, 10(4), 1-15.

4. Garcia, R. (2022). Thermal Management in 3.3kV Motor Design. Power Electronics and Drives, 7(1), 23-35.

5. Wilson, D. & Taylor, E. (2020). Advancements in Vacuum Pressure Impregnation for Motor Windings. IEEE Electrical Insulation Magazine, 36(4), 18-26.

6. Chen, H. et al. (2021). AI-Driven Diagnostics for High-Voltage Motor Maintenance. Artificial Intelligence in Engineering, 12(2), 78-92.