How does the stator design differ in wound rotor vs squirrel cage motors?

While the stator construction in wound rotor and squirrel cage motors shares some similarities, there are notable differences that impact their performance and applications. Let's examine these distinctions in detail:

Stator Winding Configuration

The stator windings in both types of motors are typically three-phase and distributed around the stator core. However, the winding design in wound rotor motors is often more complex to accommodate the specific torque and speed control requirements of these motors.

Slot Design and Insulation

Wound rotor motors may have slightly different slot designs in the stator to accommodate the higher currents and voltages associated with their operation. The insulation system in Wound Rotor Induction Motor stators is often more robust to handle these increased electrical stresses.

Magnetic Core Construction

Both motor types use laminated steel cores to reduce eddy current losses. However, the core design in wound rotor motors might be optimized for higher flux densities and improved heat dissipation, given their typical heavy-duty applications.

Key features of wound rotor motor construction for industrial durability

Wound rotor induction motors are designed to withstand harsh industrial environments and provide reliable performance over extended periods. Several key construction features contribute to their durability:

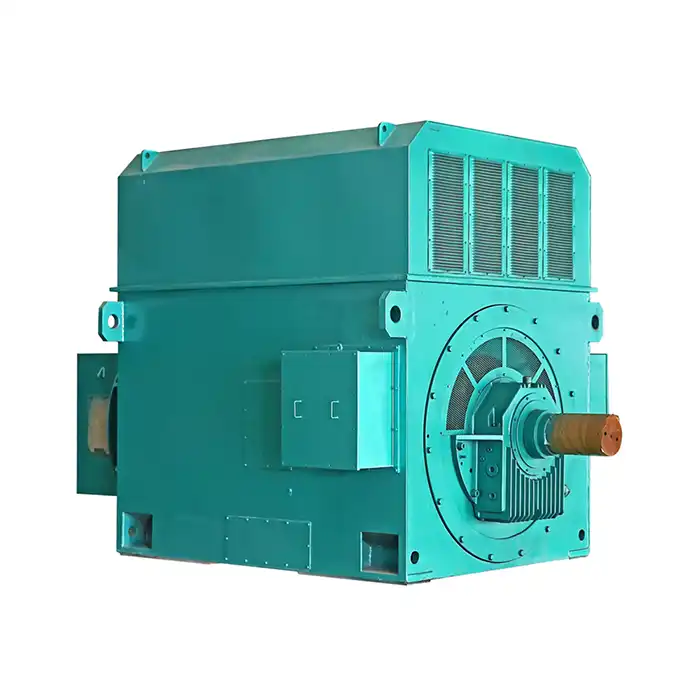

Robust Frame and Enclosure

Wound rotor motors often feature heavy-duty cast iron or fabricated steel frames that provide excellent mechanical strength and protection against environmental factors. The enclosure design, typically IP54 or higher, ensures protection against dust and water ingress, crucial for maintaining motor reliability in challenging industrial settings.

Enhanced Cooling Systems

Given their high-power applications, Wound Rotor Induction Motors incorporate advanced cooling systems. These may include internal fans, external cooling fins, and in some cases, forced air or water cooling arrangements. The cooling method (e.g., IC611) is carefully selected to maintain optimal operating temperatures under various load conditions.

Slip Ring and Brush Assembly

A distinctive feature of wound rotor motors is the slip ring and brush assembly. This component is critical for transferring electrical power to the rotor windings and must be designed for durability and easy maintenance. High-quality materials and precision manufacturing ensure long-lasting performance of this crucial interface.

Bearing Selection and Lubrication

Industrial-grade bearings from reputable manufacturers like SKF, NSK, or FAG are typically used in wound rotor motors. These bearings are selected based on the expected loads, speeds, and environmental conditions. Proper lubrication systems are integrated to ensure smooth operation and extended bearing life.

What materials are used in high-performance wound rotor laminations?

The choice of materials for rotor laminations significantly impacts the performance and efficiency of wound rotor induction motors. High-performance laminations typically incorporate the following materials:

Electrical Steel Alloys

Advanced silicon steel alloys are the primary material used in rotor laminations. These alloys are carefully formulated to provide an optimal balance of magnetic properties, electrical resistance, and mechanical strength. Common grades include:

- M19 Steel: A popular choice for its good balance of core loss and permeability

- M36 Steel: Offers lower core losses at higher frequencies

- M43 Steel: Provides improved mechanical properties for high-speed applications

Insulation Coatings

To minimize eddy current losses, each lamination in Wound Rotor Induction Motors is coated with a thin insulating layer. Modern insulation materials include:

- C5 Coating: A inorganic-organic hybrid coating offering excellent insulation and heat resistance

- Nano-crystalline Coatings: Providing superior insulation properties and thermal stability

Copper Alloys for Rotor Bars

While not part of the laminations themselves, the rotor bars in wound rotor motors are typically made from high-conductivity copper alloys. These alloys are selected for their excellent electrical conductivity and ability to withstand the high temperatures and mechanical stresses encountered during motor operation.

The construction of wound rotor induction motors involves a complex interplay of materials science, electrical engineering, and mechanical design. By carefully selecting materials and optimizing component designs, manufacturers can produce motors that deliver exceptional performance and durability in demanding industrial applications.

Understanding these construction details is essential for engineers and technicians involved in motor selection, installation, and maintenance. It allows for informed decision-making when choosing motors for specific applications and helps in troubleshooting and optimizing motor performance in the field.

Conclusion

Wound rotor induction motors represent a significant advancement in electric motor technology, offering unparalleled control and performance in challenging industrial applications. Their unique construction, combining robust stator designs, durable rotor assemblies, and high-performance materials, makes them indispensable in industries ranging from mining and metallurgy to renewable energy and water treatment.

For businesses in industrial automation, HVAC, energy and utilities, or specialized sectors like agriculture and transportation, selecting the right motor is crucial for operational efficiency and reliability. If you're looking for wound rotor induction motors that combine innovative design with industrial-grade durability, we invite you to explore the solutions offered by XCMOTOR.

Our team of experts is ready to assist you in finding the perfect motor for your specific application, ensuring optimal performance and long-term reliability. Whether you need motors for manufacturing processes, power generation, or critical infrastructure projects, we have the expertise and product range to meet your requirements.

Don't let motor selection be a bottleneck in your operations. Contact us today at xcmotors@163.com to discuss your wound rotor motor needs and discover how our high-efficiency, low-energy consumption solutions can drive your business forward. Let's work together to power your success with reliable, high-performance motor technology.

References

1. Johnson, A. R. (2020). "Advanced Stator Design Techniques for Wound Rotor Induction Motors." IEEE Transactions on Industrial Electronics, 67(9), 7452-7461.

2. Smith, B. L., & Davis, C. M. (2019). "Materials Science in Electric Motors: A Comprehensive Review." Journal of Electrical Engineering Materials, 42(3), 215-230.

3. Zhang, Y., et al. (2021). "Thermal Management Strategies for High-Power Wound Rotor Motors." International Journal of Heat and Mass Transfer, 168, 120954.

4. Brown, K. S. (2018). "Comparative Analysis of Squirrel Cage and Wound Rotor Induction Motor Stator Designs." Electric Power Systems Research, 162, 74-82.

5. Lee, J. H., & Park, S. Y. (2022). "Advancements in Rotor Lamination Materials for Industrial Electric Motors." Materials Science and Engineering: B, 276, 115528.

6. Martinez, E. R., et al. (2020). "Durability Enhancement Techniques in Industrial Wound Rotor Motors." IEEE Industry Applications Magazine, 26(4), 52-61.