The five main parts of slip ring rotor motors are what allow them to operate very well in industrial settings. The machine wouldn't function without the stator, which generates the magnetic field. The wound rotor, which is connected to the machine via resistance connections on the outside, is another crucial part. A smooth functioning is guaranteed by precise bearings, and slip rings facilitate the flow of electrical current between the spinning and stationary components. These components of slip ring rotor motors are crucial for engineers and maintenance workers to understand in order to enhance performance, decrease downtime, and extend equipment lifespan in demanding industrial circumstances.

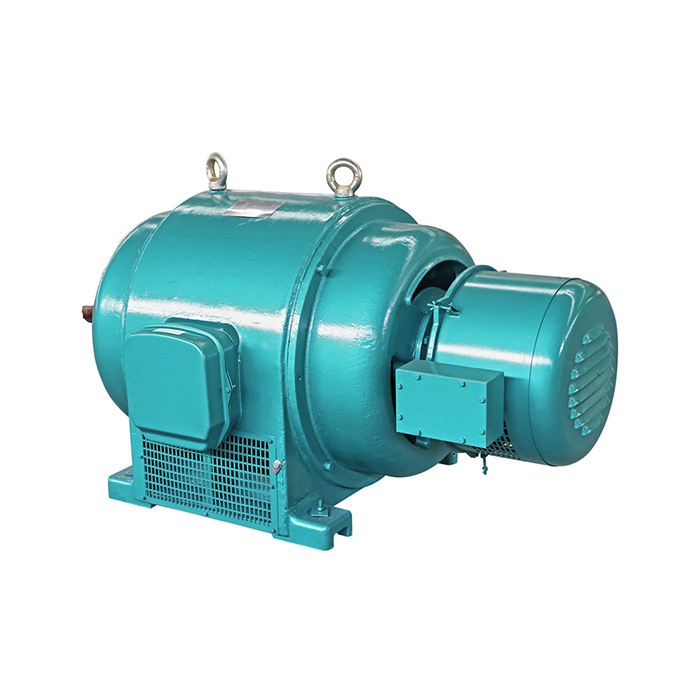

Series:YRQ

Voltage range:380V±5%

Power range:45-800kW

Protection level:IP23

Application:YRQ(JR) series medium-sized motors can drive a variety of different machinery, such as fans, compressors, water pumps, crushers, ball mills, cutting machine tools, transportation machinery and other equipment, and can be used in coal mines, machinery industries, power plants and various industrial and mining enterprises. Used as prime mover.

Advantage: The JR series medium-sized motors have very powerful driving capabilities and can not only drive conventional mechanical equipment, but also some complex mechanical equipment. For example, it can drive heavy machinery such as ships, cranes, and wind turbines, as well as small household appliances, purifiers, compressors, etc.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

What Are the Essential Components of a Slip Ring Rotor Motor?

The engineering of wound rotor acceptance engines includes modern building that empowers predominant control characteristics. Each component plays a basic part in the motor's capacity to convey high starting torque while keeping up fabulous speed control capabilities.

Stator

The stator serves as the stationary electromagnetic component that makes the turning attractive field basic for engine operation. This component houses the essential windings and keeps up basic keenness all through the slip ring rotor motor's operational life.

Constructed from high-grade covered silicon steel, the stator minimizes vortex current misfortunes while maximizing attractive flux thickness. The three-phase windings disperse equally around the stator center, making an attractive field when energized. The quality of stator development has a coordinate effect on engine proficiency, with our YRQ arrangement engines accomplishing ideal execution through exactness fabricating techniques.

The stator plan obliges voltage ranges of 380V±5% and bolsters control yields from 45kW to 800kW, making it appropriate for differing mechanical applications, including cement plants, crushers, and water treatment facilities.

Rotor

Unlike squirrel cage plans, the wound rotor highlights three-phase windings associated with outside resistance through slip rings. This setup empowers prevalent beginning characteristics and speed control capabilities.

The rotor windings are associated to slip rings mounted on the shaft, permitting for the addition of outside resistance during startup. This plan decreases inrush current to 350-450% of appraised current while producing beginning torque up to 280% of evaluated values. The strong development withstands mechanical stresses experienced in heavy-duty applications such as ball plants and mining equipment.

Our exact fabrication guarantees legitimate rotor adjust and negligible vibration, contributing to expanded bearing life and decreased support requirements over different mechanical industries.

Slip Rings

Slip rings work as the basic interface between the turning rotor circuit and the stationary outside resistance. These components empower nonstop electrical association during turn, encouraging speed and torque control.

Manufactured from high-conductivity copper or brass with specialized surface coatings, slip rings stand up to wear and erosion. The smooth surface wrap up guarantees steady electrical contact while minimizing brush wear. Legitimate slip ring upkeep includes customary review for surface abnormalities, satisfactory oil, and provoke substitution when wear limits are reached.

The slip ring gathering must withstand nonstop operation at speeds extending from 500 to 1500 rpm while keeping up solid electrical contact. Quality slip rings contribute to engine unwavering quality and operational proficiency in demanding environments.

Brushes

Slip rings work as the basic interface between the turning rotor circuit and the stationary outside resistance. These components empower nonstop electrical association during turn, encouraging speed and torque control.

Manufactured from high-conductivity copper or brass with specialized surface coatings, slip rings stand up to wear and erosion. The smooth surface wrap up guarantees steady electrical contact while minimizing brush wear. Legitimate slip ring upkeep includes customary review for surface abnormalities, satisfactory oil, and provoke substitution when wear limits are reached.

The slip ring gathering must withstand nonstop operation at speeds extending from 500 to 1500 rpm while keeping up solid electrical contact. Quality slip rings contribute to engine unwavering quality and operational proficiency in demanding environments.

Bearings

Precision heading back the rotor gathering while minimizing contact and wear. Bearing choice altogether impacts engine unwavering quality, operational noise, and upkeep intervals.

Our engines utilize premium SKF, NSK, or FAG bearings chosen for particular application necessities. These headings handle outspread and hub loads while keeping up exact shaft arrangement fundamental for appropriate discuss hole clearance. Appropriately checking oil and temperature extends bearing life and avoids untimely failure.

Bearing substitution alternatives suit client inclinations while keeping up unique hardware determinations and execution characteristics.

How Does a Slip Ring Rotor Motor Work?

Working Principle

Wound rotor acceptance engines work on electromagnetic acceptance standards whereas giving predominant control characteristics compared to standard squirrel cage plans. The turning attractive field created by stator windings actuates streams in the rotor circuit, producing torque through electromagnetic interaction.

External resistance inclusion amid startup diminishes inrush current while keeping up tall beginning torque. As engine speed increments, resistance diminishes continuously, permitting the engine to reach the appraised speed proficiently. This control instrument empowers the smooth speeding up of high-inertia loads common in mechanical applications.

Electrical and Mechanical Processes

The interaction between electrical and mechanical frameworks determines, in general, engine execution and effectiveness. Rotor current magnitude depends on slip, which changes with stack conditions and outside resistance settings.

Mechanical torque generation comes about from the interaction between rotor current and stator attractive field. Variable outside resistance permits exact torque control, making these engines perfect for applications requiring controlled increasing speed or variable speed operation. The vigorous mechanical development handles the demanding requirements of mechanical applications while keeping up operational reliability.

Advantages of Slip Ring Rotor Motors

Performance Benefits

Slip ring rotor motors deliver exceptional starting performance and operational flexibility that distinguishes them from other motor types. These performance advantages make them particularly valuable in heavy industrial applications.

Key performance advantages include:

- High Starting Torque: Achieving up to 280% of rated torque enables reliable startup of high-inertia loads without excessive current draw or mechanical stress on connected equipment.

- Reduced Starting Current: Limiting inrush current to 350-450% of rated values minimizes electrical system stress and reduces voltage dips that could affect other connected equipment.

- Speed Control Capability: External resistance variation provides effective speed control for applications requiring variable operating speeds without additional electronic controls.

- Excellent Overload Capacity: Robust construction handles temporary overload conditions while maintaining operational stability and protecting connected machinery.

These performance characteristics enable reliable operation in challenging industrial environments while reducing operational costs and maintenance requirements.

Comparison with Other Motors

Wound rotor engines offer unmistakable advantages over squirrel cage and brushless plans in particular applications. Whereas squirrel cage engines give effortlessness and lower support, they need the beginning torque and speed control capabilities basic for overwhelming mechanical loads.

Compared to variable recurrence drive frameworks, wound rotor engines provide dependable execution without complex electronic controls vulnerable to electrical obstructions common in mechanical situations. The mechanical resistance control gives vigorous operation in unforgiving conditions while keeping up exact torque characteristics.

Applications of Slip Ring Rotor Motors

Industrial Applications

Wound rotor acceptance engines exceed expectations in requesting mechanical applications requiring high starting torque and dependable operation. These engines serve basic parts across different industry sectors.

Primary applications incorporate cement plants, ball plants, crushers, transports, pumps, compressors, and mining hardware. The capacity to handle tall starting torque necessities makes these engines especially profitable in fabric handling and preparing applications where smooth increasing speed avoids mechanical harm and operational disruptions.

Power era offices depend on these engines for auxiliary gear such as cooling water pumps and fuel taking care of frameworks. The strong development and solid execution characteristics guarantee ceaseless operation in basic utility applications.

Emerging Trends

Industry improvements center on upgrading engine effectiveness and integrating computerized observing capabilities. Progressed bearing innovations and moved forward separator frameworks amplify operational life while decreasing support requirements.

Integration with condition checking frameworks empowers prescient upkeep procedures that optimize gear accessibility while minimizing unforeseen disappointments. These innovations propel position wound rotor engines as dependable arrangements for advancing mechanical computerization requirements.

XCMOTOR: Leading Slip Ring Rotor Motor Solutions

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides comprehensive power equipment solutions for industrial customers worldwide. Our expertise in wound rotor motor technology serves diverse applications across manufacturing, mining, and utility sectors.

We specialize in YRQ series medium-sized motors ranging from 45kW to 800kW, designed for demanding industrial applications. Our commitment to quality ensures reliable performance in challenging operating environments while maintaining competitive pricing and responsive customer support.

Our unique advantages include original parts from trusted brands, fast delivery with free shipping, 30-day return policies, and dedicated support available weekends. Premium SKF, NSK, and FAG bearings provide reliability while accommodating customer preferences for specific brand requirements.

Conclusion

Understanding the fundamental components of slip ring rotor motor empowers educated choices with respect to engine choice, support planning, and operational optimization. The stator, wound rotor, slip rings, brushes, and heading work together to give remarkable beginning characteristics and operational adaptability fundamental for demanding mechanical applications. These engines exceed expectations in applications requiring tall starting torque, speed control capabilities, and dependable execution beneath challenging working conditions. Legitimate component determination, normal upkeep, and quality manufacturing guarantee ideal engine execution all through the gear lifecycle, making wound rotor engines important resources for mechanical operations around the world.

Frequently Asked Questions

Q1: What are the main differences between slip ring and squirrel cage motors?

A: Slip ring motors feature wound rotors with external resistance connections, enabling high starting torque and speed control capabilities. Squirrel cage motors use cast aluminum rotors with fixed characteristics, offering simplicity but limited starting performance and no speed control without additional electronic drives.

Q2: How often should slip ring motors be serviced?

A: Regular maintenance intervals depend on operating conditions, but typical schedules include monthly brush inspections, quarterly slip ring cleaning, and annual comprehensive inspections including bearing lubrication and insulation testing. Harsh operating environments may require more frequent service intervals.

Q3: Can slip ring motors be used in hazardous environments?

A: Standard slip ring motors with IP23 protection are suitable for general industrial environments. Hazardous location applications require specialized enclosures and certifications meeting specific safety standards. Consult with motor specialists to determine appropriate configurations for classified areas.

Partner with XCMOTOR for Premium Slip Ring Rotor Motor Solutions

Selecting the right slip ring rotor motor manufacturer guarantees ideal execution and long-term reliability for your mechanical applications. XCMOTOR combines decades of designing mastery with progressive fabricating capabilities to provide predominant wound rotor engine solutions.

Our comprehensive item line meets differing control necessities from 45kW to 800kW while keeping up reliable quality guidelines. The vigorous development and premium components guarantee solid operation in demanding mechanical situations, including mining, cement generation, and control era facilities.

Experience the distinction that quality design makes in your operations. Our specialized group gives master direction for engine choice, establishment planning, and support optimization. With quick conveyance, competitive estimating, and comprehensive guarantee scope, XCMOTOR conveys esteem throughout the gear lifecycle.

Ready to enhance your industrial operations with reliable slip ring rotor motor solutions? Contact us at xcmotors@163.com to discuss your specific requirements and discover how our expertise can optimize your equipment performance. Visit motorxc.com for detailed specifications and technical documentation supporting your project planning needs.