The Benefits of Using VFD Duty Motors in Precision Applications

VFD duty motors are the most reliable and accurate way to control speed and ensure uniform performance in high-precision applications. These special motors work perfectly with variable frequency drives to give better control over power and lower energy use in a wide range of industry settings. VFD duty motors, on the other hand, can handle constant changes in speed while still performing at their best. They are great for demanding precision tasks where regular motors often fail to meet strict requirements because they are built to last and have better protection systems.

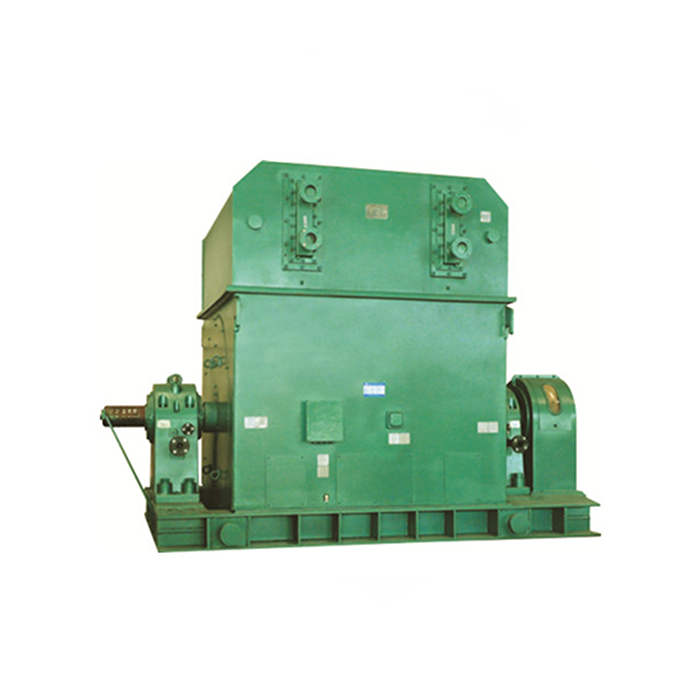

Series:YVFE5

Frequency conversion range:30hz~50hz,5hz~70hz,5hz~100hz

Power range:0.75-1000kW

Protection level:IP55

Application:are suitable for driving various mechanical equipment that require continuous and frequent forward and reverse rotation, such as steel rolling, lifting, transportation, machine tools, printing and dyeing, papermaking, chemicals, textiles, pharmaceuticals, etc., and can be used with various domestic and foreign variable frequency power supplies.

Advantage:high efficiency, wide speed range, high precision, stable operation, and easy operation and maintenance.

Certificate:installation dimensions comply with International Electrotechnical Commission (IEC) standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding VFD Duty Motor Technology

Industrial motor control systems have changed a lot because of variable frequency drive technology. VFD duty motors have special shielding and windings that are made to handle the electrical pressures that PWM inverters cause. The improved insulation class F protects very well against voltage spikes and harmonic distortions that happen a lot in frequency converter applications.

Motor control systems utilizing these specialized units achieve remarkable precision through advanced drive parameters. The frequency range capabilities spanning from 5Hz to 100Hz enable precise speed regulation across various operational requirements. This wide frequency spectrum supports both constant torque and variable torque applications effectively.

These motors' better duty cycle performance is very helpful for industrial control systems. The strong design has strengthened bearings and adjusted wheels that reduce shaking and make sure the motor runs smoothly over a wide speed range.

Core Benefits of VFD Duty Motors in Precision Applications

Enhanced Speed Control and Accuracy

Precision applications require exact speed control that traditional AC motors cannot provide. VFD duty motors deliver speed regulation accuracy within 0.1% of the set point. This exceptional precision stems from the motor's ability to respond instantly to frequency changes from the inverter.

The soft start capabilities eliminate mechanical stress during startup sequences. Load management becomes significantly more efficient as operators can adjust speeds gradually rather than relying on mechanical controls. This precise control reduces wear on mechanical components and extends equipment lifespan.

Superior Energy Efficiency Performance

Energy efficiency improvements of 15-30% are common when upgrading to VFD duty motors. The IE5 efficiency rating ensures maximum energy conversion while minimizing waste heat generation. Variable speed operation allows motors to match load requirements precisely, eliminating energy waste from oversized applications.

Overheating may lead to a decrease in efficiency, which can be avoided by thermal protection systems that continually monitor operational temperatures. In spite of lengthy durations of operation at decreased speeds, the enhanced cooling architecture is able to maintain constant performance.

Robust Overload Protection Features

Protection against electrical and mechanical failures is provided by advanced motor protection systems. It is the responsibility of overload protection circuits to monitor current levels and make adjustments to operation automatically in order to avoid harm. Internal components are protected from dust and moisture infiltration due to the IP55 protection level.

In order to prevent failures from occurring, vibration monitoring capabilities may identify bearing wear and mechanical imbalances before they occur. Reactive maintenance solutions are substantially more expensive than this predictive maintenance strategy, which results in a large reduction in both downtime and maintenance expenditures.

Key Performance Parameters and Indicators

Power and Frequency Specifications

Applications ranging from tiny precision equipment to huge industrial systems may be accommodated by the power range that extends from 0.75 kW to an impressive 1000 kW. Multiple voltage choices, such as 380V, 400V, 415V, and 660V, provide flexibility to meet the needs of a wide range of potential electrical infrastructure applications.

Frequency conversion capabilities across three distinct ranges serve different precision needs. The 30Hz to 50Hz range suits standard industrial applications, while the 5Hz to 70Hz range provides extended low-speed operation. The 5Hz to 100Hz range offers maximum flexibility for specialized precision applications requiring extreme speed variations.

Torque Control Characteristics

Constant torque capability maintains full rated torque down to 10Hz operation. Variable torque applications benefit from the 20:1 speed range without performance degradation. This wide operational range eliminates the need for multiple motor sizes in many applications.

The precision-balanced rotors ensure smooth torque delivery across the entire speed spectrum. Control algorithms optimize torque response for rapid acceleration and deceleration cycles without mechanical shock.

Temperature and Environmental Ratings

Class B temperature rise limits ensure reliable operation in challenging environments. The reinforced insulation systems withstand temperature fluctuations common in industrial settings. Optional Class H insulation provides additional protection for extreme temperature applications.

The TEFC cooling system maintains optimal operating temperatures across the full speed range. Enhanced heat dissipation prevents performance degradation during extended low-speed operation periods.

XCMOTOR VFD Duty Motors vs. Competitive Alternatives

Superior Construction Quality

XCMOTOR employs high-grade silicon steel laminations that reduce core losses and improve efficiency. The precision winding techniques using copper conductors ensure optimal electrical performance and longevity. Premium bearings from trusted manufacturers provide extended operational life with minimal maintenance requirements. Our VFD duty motors are specifically designed to handle variable frequency drive applications, offering enhanced control and reliability. The C45 steel shaft construction offers exceptional strength and precision. Stainless steel options accommodate corrosive environments where standard materials would fail prematurely.

Advanced Design Features

Power electronics integration considers harmonic distortion effects from modern inverter systems. The enhanced insulation design provides superior protection against voltage spikes and electrical stress. These design improvements result in significantly longer motor life compared to standard industrial motors.

Quality control processes ensure each motor meets strict performance specifications before shipment. Comprehensive testing validates efficiency ratings, vibration levels, and electrical characteristics.

Comprehensive Standards Compliance

IEC standard compliance ensures worldwide compatibility and reliability. CE certification validates European safety and performance requirements. ISO 9001:2015 quality management systems guarantee consistent manufacturing quality.

Maximizing Benefits Through Proper Implementation

Selection Guidelines for Optimal Performance

Proper motor sizing requires careful analysis of load characteristics and duty cycles. Continuous duty applications need different specifications than intermittent operations. The speed range requirements determine the appropriate frequency conversion range selection.

Environmental conditions influence protection class requirements. Indoor applications typically use IP55 protection, while outdoor installations may require IP65 ratings. Temperature considerations affect insulation class selection and cooling system requirements.

Installation Best Practices

Proper cable selection minimizes electrical stress from PWM switching. Shielded cables reduce electromagnetic interference that can affect sensitive control systems. Grounding practices must follow manufacturer recommendations to ensure optimal performance and safety.

Ventilation requirements ensure adequate airflow for cooling systems. Mounting orientation affects cooling efficiency and bearing life. Alignment procedures prevent premature bearing wear and vibration issues.

Maintenance Strategies for Extended Life

Regular vibration monitoring detects developing problems before failures occur. Temperature monitoring identifies cooling system issues or overload conditions. Current signature analysis reveals electrical problems and load changes.

Bearing lubrication schedules depend on operating conditions and duty cycles. Insulation resistance testing validates electrical integrity over time. Connection torque verification prevents electrical failures from loose connections.

Critical Implementation Considerations

Electrical System Compatibility

Harmonic distortion from inverter switching affects electrical system design. Input and output filters may be necessary to meet electrical code requirements. Proper grounding prevents electrical noise and ensures safety compliance.

Motor cables require special consideration for VFD applications. Standard cables may not provide adequate protection against electrical stress from PWM switching. Proper cable routing prevents interference with sensitive control circuits.

Mechanical Integration Factors

Foundation requirements differ from standard motor installations due to variable speed operation. Vibration isolation may be necessary for noise-sensitive environments. Coupling selection must accommodate speed variations and dynamic loads.

Ventilation planning ensures adequate cooling airflow across all operating speeds. Reduced speed operation generates less cooling airflow, requiring additional ventilation considerations.

Conclusion

VFD duty motors are an important piece of technology for precise tasks that need to control speed precisely and work reliably. There are big practical benefits when you combine advanced motor control features with better energy savings and strong security features. XCMOTOR has a wide range of products that can be used for a variety of precise applications and come with the technical help that is needed to make them work. Investing in good VFD duty motor technology pays off in the form of lower energy costs, longer machine life, and better control of the process. You might want to update your precise applications with tried-and-true VFD duty motor solutions that make them more productive and efficient.

Frequently Asked Questions

Q1: What makes VFD duty motors different from standard AC motors?

A: VFD duty motors feature enhanced insulation systems designed to withstand electrical stresses from variable frequency drives. The specialized windings and robust construction handle continuous speed variations while maintaining optimal efficiency and performance characteristics.

Q2: How do I select the appropriate frequency range for my application?

A: The frequency range selection depends on your speed control requirements. The 30Hz-50Hz range suits standard applications, 5Hz-70Hz provides extended low-speed capability, and 5Hz-100Hz offers maximum flexibility for specialized precision applications requiring extreme speed variations.

Q3: What protection features prevent motor damage in VFD applications?

A: XCMOTOR VFD duty motors include overload protection, thermal monitoring, and IP55 environmental protection. The enhanced insulation systems protect against voltage spikes, while vibration monitoring detects mechanical issues before they cause failures.

Choose XCMOTOR for Your VFD Duty Motor Requirements

XCMOTOR delivers precision-engineered VFD duty motor solutions backed by comprehensive technical support and reliable service. Our extensive product range from 0.75kW to 1000kW serves diverse precision applications across multiple industries. As a trusted VFD duty motor manufacturer, we provide customized solutions tailored to your specific operational requirements. Experience the advantages of premium bearings, advanced insulation systems, and rigorous quality control that set our products apart in demanding precision applications. Ready to enhance your system performance? Contact us at xcmotors@163.com for expert consultation and competitive pricing.

References

1. Institute of Electrical and Electronics Engineers. "Variable Frequency Drive Applications in Industrial Motor Control Systems." IEEE Transactions on Industry Applications, 2023.

2. International Electrotechnical Commission. "Rotating Electrical Machines: Variable Speed AC Motor Drive Systems." IEC Standard Publication 60034-25, 2022.

3. Energy Efficiency and Renewable Energy Office. "Premium Efficiency Motor Selection and Application Guide for Industrial Facilities." U.S. Department of Energy, 2023.

4. National Electrical Manufacturers Association. "Motors and Generators: Application and Installation Guidelines for VFD Systems." NEMA Standards Publication MG 1-2022.

5. American Society of Mechanical Engineers. "Precision Motion Control Systems: Motor Selection and Integration Strategies." ASME Technical Paper Series, 2023.

6. Industrial Automation Society. "Advanced Motor Control Technologies for Manufacturing Applications." Automation Technology Review, Volume 45, 2023.