Maintaining a 200 HP DC electric motor is critical for ensuring consistent operational reliability and reducing overall costs in industrial environments. These motors serve essential roles in metallurgical rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, cement production, and plastic extrusion machinery. When downtime strikes heavy-duty applications, productivity losses mount quickly. Understanding maintenance needs upfront helps procurement teams select motors that align with operational demands and budget constraints. Proper upkeep maximizes motor lifespan while minimizing unplanned failures, safeguarding production continuity, and delivering long-term value for industrial clients.

ZSeries:Z

Application:Metallurgical industrial rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, instant brushing, cement, plastic extrusion machinery.

Power range:59-1600kW

Standard: JB/T9577-1999

Understanding the Operating Principles of a 200 HP DC Electric Motor

DC electric engines work on electromagnetic principles, converting electrical vitality into mechanical torque through rotor and stator interaction. The principal development incorporates armature windings, carbon brushes, and commutators, each component contributing to by and large usefulness and execution characteristics.

Core Components and Their Functions

The armature windings create the attractive field fundamental for revolution, whereas carbon brushes keep up electrical contact with the pivoting commutator. This commutator switches the current course in the armature windings, guaranteeing persistent turn. Understanding these components makes a difference in that support groups address operational necessities like control input, torque yield, and speed direction more effectively.

Performance Factors Affecting Efficiency

Efficiency evaluations for high-power DC engines depend on numerous components counting stack conditions, plan quality, and natural circumstances. Engines working in metallurgical applications confront extraordinary temperatures and tidy introduction, whereas those in papermaking offices experience dampness and chemical vapors. These natural conditions straightforwardly affect vitality utilization and long-term working costs, making legitimate support indeed more vital for maintained performance.

Key Maintenance Practices to Extend Motor Lifespan

Routine maintenance prevents degradation and ensures industrial 200 HP DC Electric Motors remain in peak operating condition. Regular inspection schedules focus on wear-prone components while addressing environmental challenges specific to different industrial applications.

Essential Inspection and Cleaning Procedures

Here are the core maintenance practices that maximize motor longevity:

- Carbon brush inspection and replacement every 6-12 months, depending on operating hours and environmental conditions

- Commutator surface cleaning and assessment for wear patterns, scoring, or carbon buildup

- Bearing lubrication using manufacturer-specified lubricants appropriate for operating temperatures

- Cooling system maintenance including fan blade cleaning and ventilation pathway clearance

- Electrical connection tightening and insulation resistance testing

These maintenance activities prevent common failure modes that plague industrial motor applications. Regular attention to these areas significantly reduces emergency repair costs and extends operational life.

Diagnostic Techniques for Early Problem Detection

Vibration examination uncovers bearing wear, misalignment, or rotor lopsidedness; sometimes, disastrous disappointment happens. Warm observing recognizes overheating conditions that can harm windings or separator frameworks. Current signature examination recognizes electrical irregularities that show creating issues inside the motor's electrical frameworks. Early conclusion permits convenient mediation, adjusting preventive upkeep with operational necessities to minimize downtime.

Comparison: 200 HP DC Motors vs AC Motors in Maintenance and Performance

When evaluating 200 HP DC Electric Motors versus AC alternatives for industrial applications, maintenance complexity and operational characteristics present distinct trade-offs that procurement professionals must carefully consider.

Maintenance Requirements and Complexity

DC engines require customary carbon brush replacement and commutator support, making continuous upkeep commitments that AC engines regularly dodge. Brushless AC engine plans dispense with these wear components totally, lessening maintenance support requirements. Be that as it may, DC engines offer predominant torque control and speed variety capabilities that make them ideal for applications requiring exact operational control, such as metal cutting machine devices and plastic expulsion machinery.

Performance Characteristics and Application Suitability

DC engines exceed expectations in applications requiring tall beginning torque and exact speed control. The 200% beginning torque capability ordinary in quality DC engine plans gives great execution for heavy-duty applications. Vitality utilization designs change by utilize case, with DC engines possibly bringing about higher maintenance-driven costs, whereas conveying predominant control execution in demanding mechanical situations. This comparison makes a difference obtainment groups wthat eigh trade-offs between life span, operational proficiency, and add up to a toll on ownership.

Selecting and Procuring High-Quality 200 HP DC Electric Motors

Procurement decisions significantly impact long-term operational success and maintenance costs. Quality 200 HP DC Electric Motors from reputable suppliers provide better reliability, longer service life, and superior support throughout the equipment lifecycle.

Supplier Evaluation and Quality Standards

Evaluating provider capabilities incorporates confirming quality certifications like ISO 9001:2015 and CE stamping compliance. These certifications show adherence to universal quality guidelines and fabrication forms. Client bolster responsiveness and save parts accessibility have become basic variables when hardware works in mission-critical applications where downtime carries critical implications.

Customization Options for Specific Applications

Industrial applications frequently require particular arrangements to coordinate one-of-a-kind operational necessities. Voltage choices extending from 220V to 750V suit distinctive control conveyance frameworks. Cover course F (155°C) gives warm assurance for high-temperature situations common in metallurgical and cement generation applications. Security classes IP23 and IP44 offer changing degrees of natural security appropriate for distinctive mechanical situations. Arranging ahead for lead times and detail necessities guarantees opportune conveyance and mitigates operational dangers in B2B acquisition scenarios.

Integrated Solutions: Enhancing Motor Reliability with Advanced Services

Modern maintenance strategies incorporate predictive technologies and continuous monitoring systems that significantly improve reliability while reducing overall maintenance costs.

Predictive Maintenance Technologies

Vibration analysis equipment detects mechanical problems before they cause equipment failure. Thermal imaging cameras identify hot spots that indicate electrical problems or cooling system deficiencies. IoT-enabled sensors provide continuous monitoring capabilities that alert maintenance teams to developing problems. These technologies enable preemptive maintenance scheduling that minimizes unplanned downtime while optimizing maintenance resource allocation.

Comprehensive Support Services

Expert installation services ensure proper motor setup and initial configuration. Technical consultation helps optimize motor selection for specific applications and operating conditions. Global after-sales coverage provides ongoing support regardless of installation location. These comprehensive services enhance motor performance while providing customers with confidence in their equipment investment decisions.

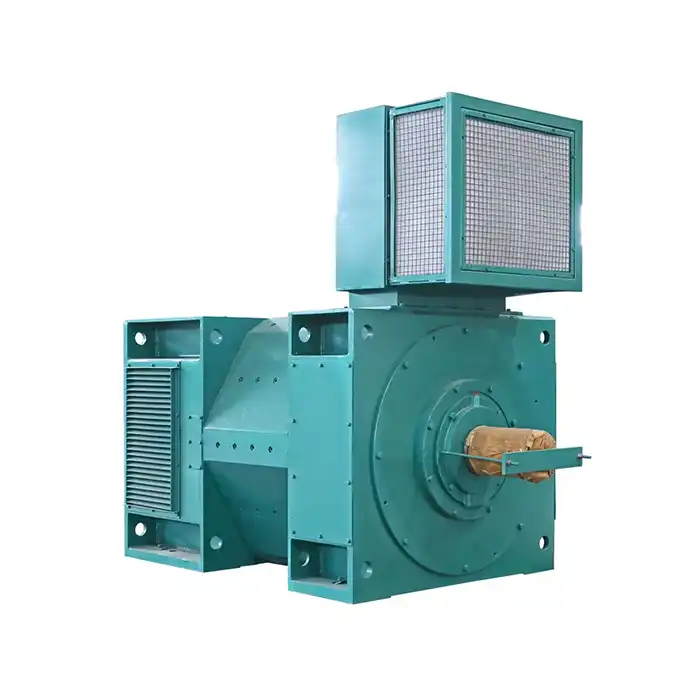

XCMOTOR Solutions for Industrial Motor Applications

XCMOTOR specializes in delivering reliable 200 HP DC Electric Motors engineered for demanding industrial environments. Our product portfolio includes motors with power output ranging from 59kW to 1600kW, specifically designed for metallurgical rolling mills, metal cutting machine tools, papermaking, dyeing and weaving, cement production, and plastic extrusion machinery applications.

Our motors feature rugged cast iron construction providing excellent durability and stress resistance. Precision-balanced rotors combined with high-quality bearings ensure smooth, vibration-free operation that extends equipment lifespan. Compact designs enable easy installation in various industrial settings, from crowded factory floors to space-constrained workshops. Technical specifications include power factors of 0.88, starting torque at 200% of full load, and overload capacity of 150% for 2 minutes.

Every motor undergoes rigorous quality control throughout production, from intricate winding processes to final assembly. Skilled technicians monitor each step, ensuring products meet the highest performance and reliability standards. Our commitment to quality extends to comprehensive customer support, including technical consultation, customized design solutions, and responsive after-sales service.

Conclusion

Proper maintenance of industrial DC motors requires understanding their operating principles, implementing systematic inspection procedures, and selecting quality equipment from reliable suppliers. Regular maintenance focusing on carbon brushes, commutators, lubrication, and cooling systems prevents costly failures while extending operational life. Predictive maintenance technologies enhance traditional approaches by enabling early problem detection and optimized maintenance scheduling. Procurement decisions impact long-term success, making supplier evaluation and quality standards critical considerations for industrial operations seeking reliable motor performance.

Frequently Asked Questions

Q1: How often should a 200 HP DC electric motor be serviced to ensure longevity?

A: Routine inspections every 3-6 months, accompanied by comprehensive annual maintenance, are essential to detect wear early, prevent failures, and maximize motor lifespan. Carbon brush replacement typically occurs every 6-12 months depending on operating conditions and usage patterns.

Q2: What are the biggest maintenance challenges for 200 HP DC motors?

A: Carbon brush wear, overheating risks, and contamination from dust or moisture pose the main challenges. Proactive monitoring and immediate repair interventions effectively mitigate these issues while preventing catastrophic equipment failure.

Q3: Can a 200 HP DC motor be upgraded or retrofitted to enhance performance?

A: Yes, upgrades including enhanced cooling systems, improved control electronics, and modern monitoring equipment can improve efficiency, reliability, and extend service life. However, major modifications should be evaluated against replacement costs and operational requirements.

Partner with XCMOTOR for Reliable Motor Solutions

Maximize the performance and lifespan of your industrial motors with XCMOTOR's proven solutions. As a trusted 200 HP DC electric motor manufacturer, we provide customizable motors engineered for efficiency and durability in demanding industrial environments. Our comprehensive support includes technical consultation, expert installation, and responsive after-sales service designed to minimize downtime and maximize return on investment. Contact us at xcmotors@163.com to discuss your specific motor requirements and discover how our expertise can enhance your industrial operations.

References

1. IEEE Standard 112-2017, IEEE Standard Test Procedure for Polyphase Induction Motors and Generators, Institute of Electrical and Electronics Engineers

2. NEMA MG 1-2016, Motors and Generators Standard, National Electrical Manufacturers Association

3. Chapman, Stephen J. "Electric Machinery Fundamentals, Fifth Edition." McGraw-Hill Education, 2012

4. Fitzgerald, A.E., Kingsley, Charles Jr., and Umans, Stephen D. "Electric Machinery, Seventh Edition." McGraw-Hill Education, 2013

5. IEEE Standard 43-2013, IEEE Recommended Practice for Testing Insulation Resistance of Rotating Machinery, Institute of Electrical and Electronics Engineers

6. Bonnett, Austin H. and Soukup, George C. "Rotor Failures in Squirrel Cage Induction Motors." IEEE Transactions on Industry Applications, Volume 42, Issue 4, 2006