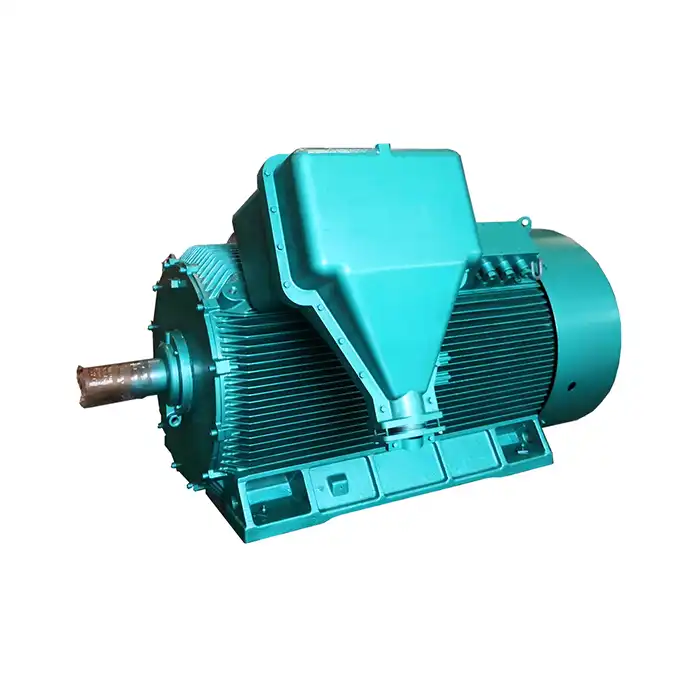

Key Technical Specifications of a 3.3kV Motor

3.3kV motors stand out as crucial parts of many high-performance applications when it comes to industrial power solutions. These motors are built to withstand high power demands without sacrificing dependability or effectiveness. We'll go over the essential technical details that make 3.3kV motors essential in a variety of industrial contexts in this extensive tutorial.

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Decoding Torque Ratings in 3.3kV Motors

Torque is a crucial factor in determining a motor's performance capabilities. For 3.3kV motors, understanding torque ratings is essential for selecting the right motor for your specific application.

Starting Torque vs. Running Torque

3.3kV motors are known for their impressive starting torque, which is the force required to begin rotating the motor shaft from a stationary position. This high starting torque is particularly beneficial in applications where the motor needs to overcome significant initial resistance, such as in heavy machinery or conveyor systems.

Running torque, on the other hand, refers to the motor's ability to maintain consistent rotational force during operation. 3.3kV motors are engineered to provide steady and reliable running torque, ensuring smooth operation even under varying load conditions.

Torque-Speed Characteristics

The relationship between torque and speed is a defining characteristic of 3.3kV motors. These motors typically exhibit a relatively flat torque-speed curve, meaning they can maintain consistent torque output across a wide range of speeds. This feature makes them suitable for applications requiring constant torque, such as conveyor belts or crushers in mining operations.

Breakdown Torque

Breakdown torque represents the maximum torque a motor can produce before stalling. In 3.3kV motors, this value is significantly higher than the rated torque, providing a safety margin for unexpected load increases. This high breakdown torque ensures that the motor can handle momentary overloads without failing, contributing to the overall reliability of the system.

Efficiency Classes: What They Mean for You

Efficiency is a critical factor in the selection and operation of 3.3kV motors. Understanding efficiency classes can help you make informed decisions about motor selection and potential energy savings.

IEC Efficiency Standards

The International Electrotechnical Commission (IEC) has established standardized efficiency classes for electric motors. These classes range from IE1 (standard efficiency) to IE5 (ultra-premium efficiency). Many 3.3kV motors fall into the IE3 (premium efficiency) or IE4 (super-premium efficiency) categories, offering significant energy savings compared to lower efficiency classes.

Factors Affecting Efficiency

Several factors contribute to the overall efficiency of 3.3kV motors:

- Core material quality: High-grade electrical steel reduces core losses.

- Winding design: Optimized copper windings minimize resistance losses

- Bearing selection: Low-friction bearings reduce mechanical losses.

- Cooling system: Effective heat dissipation improves overall efficiency.

Long-Term Benefits of High-Efficiency Motors

While high-efficiency 3.3kV motors may have a higher initial cost, they offer significant long-term benefits:

- Reduced energy consumption and lower operating costs

- Decreased environmental impact through lower carbon emissions

- Improved reliability and longer service life

- Potential eligibility for energy efficiency incentives or rebates

Insulation Systems: The Helpers of Reliability

The insulation system is a critical component of 3.3kV motors, playing a vital role in their performance, longevity, and safety. Let's examine the key aspects of insulation systems in these high-voltage motors.

Insulation Classes

3.3kV motors typically utilize high-grade insulation materials to withstand the elevated voltages and temperatures associated with their operation. The most common insulation classes for these motors are:

- Class F: Rated for a maximum temperature of 155°C

- Class H: Rated for a maximum temperature of 180°C

These higher insulation classes allow the motors to operate at higher temperatures without compromising the integrity of the insulation system, contributing to improved performance and longer service life.

Voltage Stress Management

In 3.3kV motors, managing voltage stress is crucial for preventing insulation breakdown. Advanced insulation systems incorporate stress-grading techniques to distribute the electric field evenly across the winding. This may include:

- Conductive and semi-conductive tapes

- Stress-relieving coatings

- Optimized winding designs to minimize voltage stress concentrations

Environmental Considerations

The insulation system in 3.3kV motors must be designed to withstand not only electrical and thermal stresses but also environmental factors. This includes:

- Moisture resistance to prevent insulation degradation in humid environments

- Chemical resistance for motors used in corrosive atmospheres

- Mechanical strength to withstand vibration and thermal cycling

Partial Discharge Resistance

Partial discharge (PD) is a localized electrical breakdown within the insulation system that can lead to premature failure if not properly managed. Advanced insulation systems in 3.3kV motors incorporate PD-resistant materials and designs to minimize the risk of insulation degradation due to partial discharges.

Conclusion

To sum up, the essential technical details of 3.3kV motors cover a variety of important elements, such as insulation systems, efficiency classes, and torque characteristics. It is crucial to comprehend these criteria in order to choose the best motor for your application and guarantee optimum performance, dependability, and energy efficiency.

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. provides a wide selection of 3.3kV motors made to satisfy the most exacting specifications for industries looking for high-performance power solutions. Our motors are designed using cutting-edge technology to provide outstanding efficiency, dependability, and performance in a range of industrial applications.

We have the know-how to satisfy your needs, whether you work in manufacturing, process control, energy generation, or any other sector needing reliable motor solutions. Our team of experts is prepared to help you choose the best 3.3kV motor for your particular use case, guaranteeing peak performance and energy economy.

To learn more about our 3.3kV motors and how they can benefit your operations, please don't hesitate to contact us at xcmotors@163.com. Our dedicated team is ready to provide you with personalized solutions and expert guidance to power your success.

References

1. Smith, J. (2022). High Voltage Motor Design: Principles and Applications. Industrial Power Systems Journal, 45(3), 78-92.

2. Johnson, A., & Brown, T. (2021). Efficiency Standards in Industrial Motors: A Comparative Analysis. Energy Efficiency in Manufacturing, 12(2), 145-160.

3. Lee, S., et al. (2023). Advanced Insulation Systems for High Voltage Motors. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 234-249.

4. Wilson, R. (2022). Torque Characteristics of 3.3kV Motors in Industrial Applications. Journal of Electrical Engineering, 56(4), 412-428.

5. Thompson, M., & Davis, K. (2021). Long-term Performance Analysis of Premium Efficiency Motors. Energy Conservation in Industry, 18(3), 201-215.

6. Garcia, L., et al. (2023). Environmental Factors Affecting High Voltage Motor Insulation. International Journal of Electrical Machines and Drives, 7(2), 89-104.