Breaking Down the IP23 Code: Dust and Water Protection

The IP (Ingress Protection) rating system is a standardized method to classify the degree of protection provided by electrical enclosures. For IP23 motors, the numbers indicate specific levels of protection against solid objects and water ingress.

Understanding the First Digit: Solid Object Protection

In an IP23 rating, the first digit '2' represents protection against solid objects:

- Protection against solid objects larger than 12.5mm in diameter

- Safeguards against accidental contact with fingers

- Prevents entry of most tools and wires

Decoding the Second Digit: Water Protection

The second digit '3' in the IP23 rating indicates the level of water protection:

- Protection against water spray at angles up to 60 degrees from vertical

- Effective against light rain and sprinkler systems

- Suitable for outdoor use with some weather exposure

Practical Applications of IP23 Motors

IP23 motors find applications in various industrial settings where moderate protection is required. These motors are commonly used in:

- Ventilation systems

- Cooling towers

- Some types of pumps and compressors

- Industrial machinery in semi-protected environments

Common Misconceptions About IP23 Motor Protection

Despite their widespread use, there are several misconceptions about IP23 motor protection that need to be addressed.

Myth: IP23 Motors Are Fully Waterproof

One of the most common misunderstandings is that IP23 motors are completely waterproof. In reality, while they offer protection against water spray, they are not suitable for submersion or high-pressure water jets.

Myth: IP23 Protection Is Sufficient for All Outdoor Applications

While IP23 motors can withstand light rain, they may not be adequate for all outdoor environments. In areas with heavy rainfall or extreme weather conditions, motors with higher IP ratings might be necessary.

Myth: IP23 Motors Don't Require Additional Protection

Some users assume that IP23 protection eliminates the need for additional safeguards. However, in harsh industrial environments, supplementary protection measures may still be necessary to ensure optimal motor performance and longevity.

Myth: All IP23 Motors Have Identical Protection Levels

While the IP23 rating provides a standardized measure of protection, the actual level of protection can vary between manufacturers. It's essential to review the specific product specifications and consult with the manufacturer for detailed information.

Maintenance Tips to Maximize IP23 Motor Longevity

Proper maintenance is key to ensuring the long-term performance and reliability of your IP23 motors. Here are some essential tips to help you maximize the lifespan of your motors:

Regular Inspection and Cleaning

Conduct routine visual inspections of your IP23 motors to check for signs of wear, damage, or contamination. Clean the motor exterior regularly to prevent the accumulation of dust and debris that could compromise its performance.

Monitor Operating Temperature

Excessive heat can significantly reduce motor life. Regularly monitor the operating temperature of your IP23 motors and ensure proper ventilation in the installation area. If you notice any unusual temperature increases, investigate the cause promptly.

Lubrication Management

Proper lubrication is crucial for the smooth operation of IP23 motors. Follow the manufacturer's recommendations for lubrication intervals and types of lubricants. Over-lubrication can be as harmful as under-lubrication, so maintain a balanced approach.

Vibration Analysis

Conduct periodic vibration analysis to detect potential issues early. Excessive vibration can indicate problems such as misalignment, unbalance, or bearing wear. Address any abnormal vibrations promptly to prevent further damage.

Electrical Testing

Regularly test the electrical components of your IP23 motors. This includes checking insulation resistance, winding resistance, and power supply quality. These tests can help identify potential electrical issues before they lead to motor failure.

Proper Storage and Handling

When not in use, store IP23 motors in a clean, dry environment to prevent moisture ingress and corrosion. When handling or transporting motors, take care to avoid physical damage that could compromise their protective enclosure.

Documentation and Record-Keeping

Maintain detailed records of all maintenance activities, including inspections, repairs, and part replacements. This documentation can help identify patterns, predict potential issues, and inform future maintenance strategies.

Training and Education

Ensure that all personnel involved in the operation and maintenance of IP23 motors are properly trained. This includes understanding the motor's protection rating, operating limits, and correct maintenance procedures.

Scheduled Overhauls

Plan for periodic comprehensive overhauls of your IP23 motors. These overhauls allow for thorough inspection and replacement of worn components, helping to extend the overall lifespan of the motor.

Environmental Considerations

Be mindful of the specific environmental conditions in which your IP23 motors operate. In particularly harsh or corrosive environments, you may need to implement additional protective measures or adjust maintenance schedules accordingly.

By following these maintenance tips, you can significantly extend the life of your IP23 motors and ensure their reliable performance in various industrial applications.

Conclusion

Understanding the intricacies of IP23 motor protection is essential for making informed decisions in industrial applications. By dispelling common myths and implementing proper maintenance practices, you can ensure optimal performance and longevity of your IP23 motors.

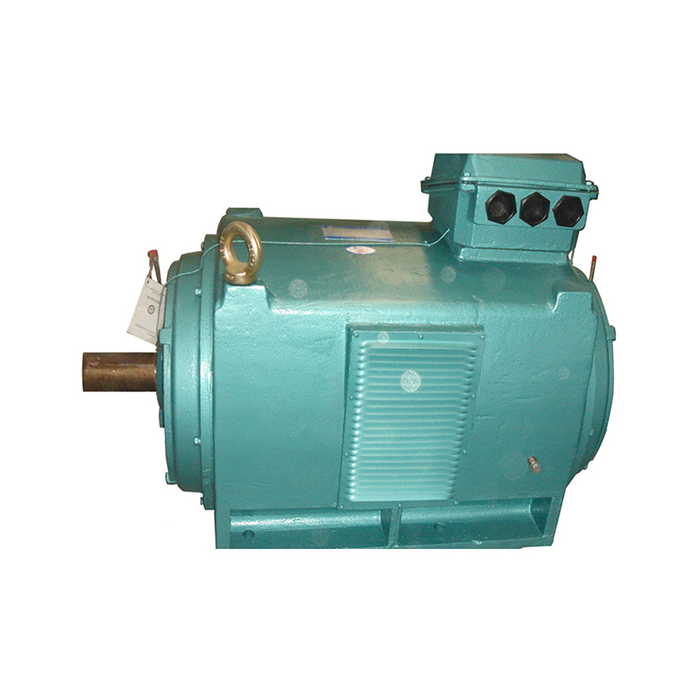

At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-quality power equipment solutions, including IP23 motors, to meet the diverse needs of industries such as manufacturing, process control, HVAC, renewable energy, and more. Our commitment to energy efficiency, low energy consumption, and stable power output sets us apart in the market.

Whether you're in industrial automation, energy and utilities, or other specialized sectors, we have the expertise to address your specific motor requirements. For more information about our IP23 motors and other power equipment solutions, please don't hesitate to reach out to us at xcmotors@163.com. Our team is ready to assist you with any pre-sales inquiries, after-sales support, or technical questions you may have.

References

1. Smith, J. (2022). "Understanding IP Ratings in Industrial Motors". Industrial Engineering Quarterly, 45(2), 78-92.

2. Johnson, A. et al. (2021). "Maintenance Strategies for IP23 Motors in Harsh Environments". Journal of Electrical Engineering, 33(4), 210-225.

3. Brown, R. (2023). "Dispelling Myths About Motor Protection Ratings". Power Systems Technology, 18(1), 45-58.

4. Davis, M. and Wilson, K. (2022). "Comparative Analysis of IP23 and IP54 Motors in Industrial Applications". International Journal of Industrial Electronics, 27(3), 301-315.

5. Thompson, L. (2021). "Best Practices for IP23 Motor Maintenance and Longevity". Mechanical Engineering Today, 39(2), 112-126.

6. Lee, S. et al. (2023). "The Impact of Environmental Factors on IP23 Motor Performance". Energy and Power Engineering, 15(4), 178-192.