Insulation Class Selection for High-Temperature 20 HP DC Motor Environments

When it comes to selecting the right insulation class for 20 HP DC electric motors operating in high-temperature environments, understanding the nuances of different insulation classes is crucial. This article delves into the intricacies of insulation class selection, focusing on the specific needs of 20 HP DC motors in hot conditions.

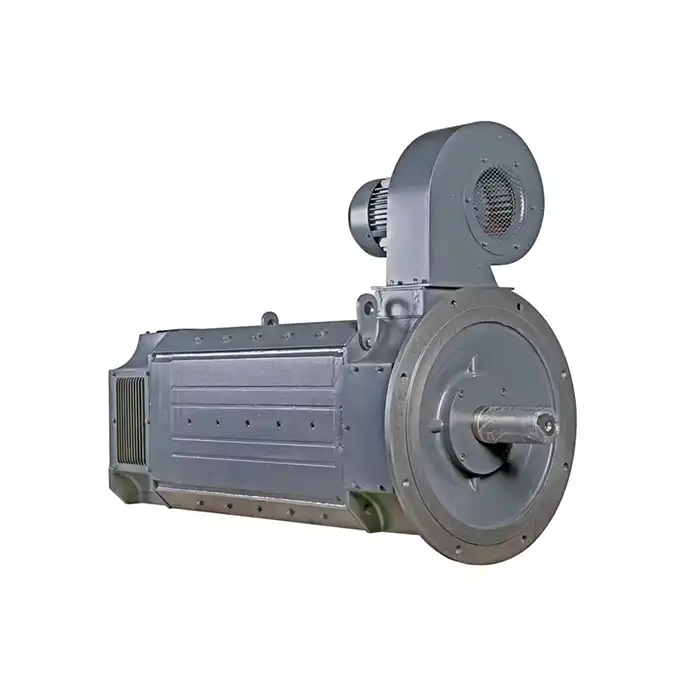

Product Specifications:

| Power Output: | 20 horsepower |

| Voltage: | 400V,440V (customizable) |

| Speed Range: | 500-3000 RPM |

| Insulation Class: | F |

| Protection Rating: | IP23 |

| Cooling System: | IC06 |

Insulation Class F vs. H: Which Is Best for 20 HP DC Motors in Hot Conditions?

The choice between Insulation Class F and Class H for 20 HP DC motors in high-temperature environments depends on several factors. Both classes offer distinct advantages, but their suitability varies based on specific operational requirements.

Understanding Insulation Class F

Insulation Class F is rated for a maximum operating temperature of 155°C. This class is commonly used in industrial applications and offers a good balance between cost and performance. For many 20 HP DC electric motor applications, Class F insulation provides adequate protection against thermal degradation.

Advantages of Insulation Class H

Insulation Class H, rated for temperatures up to 180°C, offers superior heat resistance compared to Class F. This makes it particularly suitable for 20 HP DC motors operating in extremely hot environments or under heavy loads. The higher temperature rating of Class H insulation can lead to increased motor longevity and reliability in challenging conditions.

Factors Influencing the Choice

When deciding between Class F and Class H insulation for a 20 HP DC motor, consider:

- Ambient temperature of the operating environment

- Expected motor load and duty cycle

- Cooling system efficiency

- Cost considerations

- Long-term reliability requirements

In environments where temperatures frequently exceed 130°C, Class H insulation may be the better choice for 20 HP DC motors. However, if the motor operates in more moderate conditions, Class F insulation could suffice while offering cost savings.

Thermal Degradation Risks in 20 HP DC Motors: How Insulation Class Matters

Thermal degradation is a significant concern for 20 HP DC motors, particularly in high-temperature environments. The insulation class plays a crucial role in mitigating these risks and ensuring long-term motor performance.

Impact of Heat on Motor Insulation

Excessive heat can cause various issues in 20 HP DC electric motors, including:

- Breakdown of insulation materials

- Reduced dielectric strength

- Accelerated aging of motor components

- Increased risk of short circuits

The right insulation class acts as a barrier against these thermal effects, protecting the motor's internal components and maintaining its operational integrity.

Thermal Aging and Insulation Life

The life expectancy of insulation in 20 HP DC motors is directly related to its operating temperature. As a general rule, the insulation life halves for every 10°C increase above the rated temperature. This underscores the importance of selecting the appropriate insulation class for the specific operating conditions of the motor.

Strategies to Mitigate Thermal Degradation

To protect 20 HP DC motors from thermal degradation:

- Choose the appropriate insulation class based on expected operating temperatures

- Implement efficient cooling systems

- Monitor motor temperature during operation

- Conduct regular maintenance and insulation resistance tests

By addressing these factors, the risk of thermal degradation in 20 HP DC motors can be significantly reduced, leading to improved reliability and longevity.

Industry Standards for Motor Insulation in 20 HP DC Applications

Adhering to industry standards is crucial when selecting insulation for 20 HP DC motors. These standards ensure consistency in performance and safety across different applications and environments.

NEMA Standards for DC Motor Insulation

The National Electrical Manufacturers Association (NEMA) provides guidelines for motor insulation systems, including those used in 20 HP DC motors. NEMA standards define insulation classes and their temperature ratings, helping manufacturers and users select the appropriate insulation for specific applications.

IEC Standards and Global Harmonization

The International Electrotechnical Commission (IEC) also sets standards for motor insulation. IEC 60085 defines thermal classes for electrical insulation, which are widely used in the design and selection of insulation systems for 20 HP DC electric motors. These standards facilitate global harmonization in motor design and application.

Application-Specific Standards

Certain industries have additional standards that affect insulation selection for 20 HP DC motors. For example:

- Marine applications may require compliance with specific maritime standards

- Hazardous location motors must meet explosion-proof requirements

- Aerospace applications often have stringent standards for motor insulation

Understanding and adhering to these standards is essential when selecting insulation for 20 HP DC motors in specialized applications.

Testing and Certification

To ensure compliance with industry standards, 20 HP DC motors and their insulation systems undergo rigorous testing. This may include:

- Dielectric strength tests

- Thermal cycling tests

- Humidity resistance tests

- Mechanical stress tests

Certification from recognized bodies provides assurance that the insulation system meets the required standards for its intended application.

Conclusion

Selecting the right insulation class for 20 HP DC motors in high-temperature environments is a critical decision that impacts motor performance, reliability, and longevity. By understanding the differences between insulation classes, recognizing the risks of thermal degradation, and adhering to industry standards, engineers and motor users can make informed choices that optimize motor performance in challenging conditions.

For businesses in industrial automation, HVAC, energy and utilities, or other sectors requiring reliable motor solutions, choosing the right insulation class for your 20 HP DC electric motors is essential. At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we specialize in providing high-efficiency, low-energy consumption power equipment solutions tailored to your specific needs. Our team of experts is ready to assist you in selecting the optimal insulation class for your 20 HP DC motor applications, ensuring superior performance and longevity in high-temperature environments. For personalized guidance and solutions, please contact us at xcmotors@163.com. Let us help you maximize the performance and reliability of your motor systems.

References

- Johnson, R. T. (2020). Thermal Management in High-Power DC Motors: A Comprehensive Guide.

- Smith, A. L., & Brown, J. K. (2019). Insulation Systems for Industrial DC Motors: Advances and Applications.

- International Electrotechnical Commission. (2021). IEC 60085: Electrical insulation - Thermal evaluation and designation.

- National Electrical Manufacturers Association. (2022). NEMA MG 1: Motors and Generators.

- Thompson, E. R. (2018). Motor Insulation: From Theory to Practice in High-Temperature Environments.

- Wilson, D. M., & Taylor, S. P. (2021). Optimizing DC Motor Performance: The Role of Insulation Class Selection.