The industrial landscape relies heavily on robust and efficient power generation solutions, with 6600v motor systems serving as the backbone of countless operations worldwide. These high voltage motors play a crucial role in transforming electrical energy into mechanical power across diverse sectors, from manufacturing plants to renewable energy facilities. Understanding the specific applications and benefits of 6600 volt motors helps engineers and facility managers make informed decisions about their power generation needs, ultimately improving operational efficiency and reducing energy consumption.

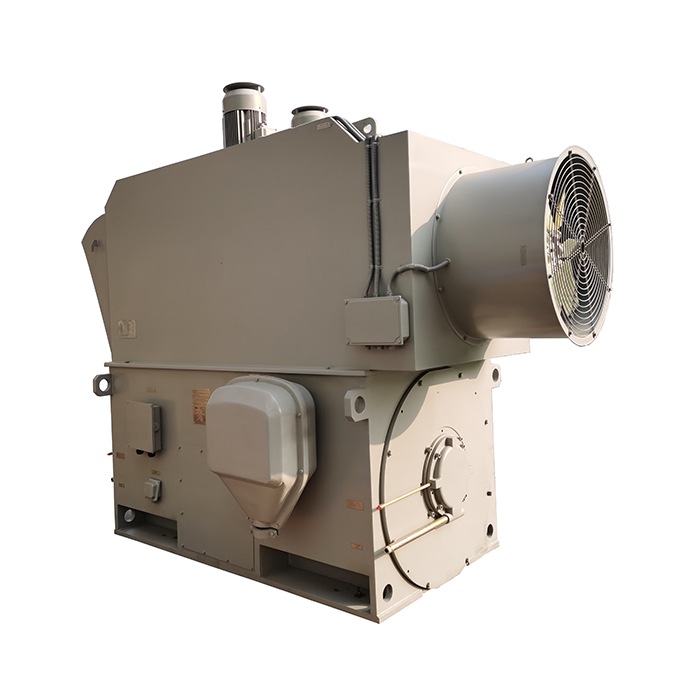

Series:YPKK

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-6300 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:low noise, low vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JJB/T12730 and JB/T12729 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Understanding High Voltage Motor Technology in Power Generation

High voltage induction motors operate at significantly elevated voltage levels compared to standard industrial motors. The 6600 volt rating represents a sweet spot in the motor industry, providing optimal balance between power output and manageable electrical infrastructure requirements. These electric drive systems deliver exceptional performance while maintaining cost-effectiveness for medium to large-scale operations.

The fundamental advantage of operating at higher voltages lies in reduced current requirements for equivalent power output. This characteristic translates into smaller conductor sizes, reduced electrical losses, and improved overall system efficiency. Synchronous motors and induction motor variants both benefit from this voltage range, offering different advantages depending on specific application requirements.

Motor efficiency becomes increasingly important as energy costs continue rising globally. Advanced motor design incorporates sophisticated cooling systems and enhanced insulation materials to handle the elevated electrical stress while maintaining reliability over extended operational periods.

Primary Applications in Manufacturing Industries

Manufacturing facilities across automotive, aerospace, electronics, and food processing sectors depend on reliable high voltage motor solutions. Large-scale production lines require consistent power delivery to maintain operational schedules and product quality standards.

Automotive manufacturing plants utilize these 6600v motors for powering assembly line conveyors, stamping presses, and robotic welding stations. The consistent torque delivery ensures precise positioning and timing critical for modern automotive production processes. Motor control systems integrate seamlessly with existing automation infrastructure, providing smooth acceleration and deceleration profiles.

Aerospace manufacturing demands exceptional precision and reliability. These motors drive CNC machining centers, automated drilling equipment, and component testing systems. The superior load capacity handles varying operational demands while maintaining tight tolerances required for aircraft component production.

Electronics manufacturing benefits from the stable power characteristics of high voltage systems. Clean power delivery minimizes electromagnetic interference that could affect sensitive electronic components during production processes. Variable frequency drives provide precise speed control for specialized manufacturing equipment.

Critical Role in Process Control Systems

Process industries rely on continuous operation of pumps, compressors, and valve actuators to maintain production flow. These applications demand motors capable of handling varying loads while maintaining consistent performance over extended periods.

Centrifugal pump applications in chemical processing facilities benefit from the high starting torque capabilities of these motor systems. The ability to overcome initial static friction and accelerate heavy pump assemblies ensures reliable startup even after extended shutdown periods. Motor protection systems monitor operating conditions and prevent damage from overload situations.

Compressor applications in petrochemical facilities require motors capable of handling significant load variations as process demands change. The robust construction and thermal management systems handle continuous operation under challenging environmental conditions. Starting current characteristics minimize electrical system disturbances during motor startup sequences.

Industrial valve control systems benefit from precise speed regulation capabilities. The combination of motor efficiency and control accuracy enables optimal process control while minimizing energy consumption. Maintenance requirements remain minimal due to the robust design characteristics.

Power Generation and Utility Applications

Electric utilities and independent power producers utilize 6600v motors for auxiliary systems supporting primary generation equipment. These applications include cooling water pumps, fuel handling systems, and emission control equipment.

Coal-fired power plants depend on these motors for coal handling conveyors, pulverizer drives, and ash handling systems. The reliability requirements in power generation facilities demand motors capable of continuous operation with minimal maintenance interruptions. The robust insulation systems handle the harsh environment typical of power generation facilities.

Natural gas facilities use these motors for gas compression systems and cooling applications. The electromagnetic compatibility characteristics ensure reliable operation in environments with significant electrical interference from other power equipment. Energy consumption optimization contributes to overall plant efficiency improvements.

Hydroelectric facilities employ these motors for gate control systems and auxiliary pumping applications. The ability to operate in high humidity environments makes them suitable for hydroelectric plant installations. Cooling system designs accommodate the unique thermal management requirements of these applications.

HVAC and Refrigeration System Integration

Large commercial and industrial HVAC systems require powerful motors for central air handling units, chiller systems, and cooling tower applications. The scale of these systems demands the power capabilities that high voltage motors provide.

Commercial refrigeration facilities, including food processing and cold storage warehouses, depend on reliable motor performance for maintaining critical temperature control. The consistent operation prevents product spoilage and maintains food safety standards. Motor design considerations include operation in low-temperature environments and condensing conditions.

Data center cooling systems utilize these motors for large-scale air conditioning equipment. The precision cooling requirements of modern data centers demand motors capable of rapid response to changing thermal loads. Variable frequency drive integration provides energy-efficient operation as cooling demands fluctuate.

Industrial process cooling applications benefit from the power factor characteristics of well-designed motor systems. The ability to maintain high efficiency across varying load conditions contributes to overall facility energy management goals.

Renewable Energy Sector Applications

Wind turbine installations employ high voltage motors for blade pitch control systems and yaw mechanisms. These applications require motors capable of precise positioning while handling significant mechanical loads from wind forces. The reliability requirements in remote wind farm locations demand robust motor designs with extended maintenance intervals.

Solar tracking systems use these motors to position large solar panel arrays for optimal sun exposure throughout the day. The precise positioning requirements combined with outdoor environmental exposure demands motors with superior weather protection and reliable performance characteristics.

Hydroelectric pump storage facilities utilize reversible motor-generator units for energy storage applications. These specialized applications require motors capable of both motoring and generating modes, with rapid transition capabilities between operating modes.

Transportation and Infrastructure Projects

Railway electrification projects employ high voltage motors for various auxiliary systems supporting train operations. These applications include station ventilation systems, platform equipment, and maintenance facility operations.

Airport ground support equipment relies on these motors for baggage handling systems, aircraft ground power units, and terminal building systems. The operational reliability requirements in aviation applications demand motors with proven track records and comprehensive support infrastructure.

Marine applications include ship propulsion systems, cargo handling equipment, and offshore platform operations. The harsh marine environment requires specialized motor designs with enhanced corrosion protection and sealed enclosures.

Key Benefits and Performance Advantages

The operational advantages of properly specified 6600v motors extend beyond basic power delivery capabilities. Energy efficiency improvements directly impact operating costs, with modern motor designs achieving efficiency ratings exceeding 95% under optimal conditions.

Reliability characteristics include extended bearing life, robust insulation systems, and comprehensive motor protection features. These design elements combine to deliver operational availability exceeding 99% in properly maintained installations. The reduced maintenance requirements translate into lower total cost of ownership over the motor lifecycle.

Power factor correction capabilities help facilities avoid utility penalties while improving overall electrical system efficiency. The ability to operate at leading or lagging power factors provides flexibility for electrical system optimization.

Installation and Maintenance Considerations

Proper installation practices ensure optimal motor performance and longevity. Foundation requirements, alignment procedures, and electrical connections must meet manufacturer specifications to avoid premature failures or reduced efficiency.

Preventive maintenance programs include regular vibration monitoring, thermal imaging, and electrical testing to identify potential issues before they cause operational disruptions. Modern condition monitoring systems provide continuous oversight of critical parameters.

Environmental considerations include ambient temperature limits, altitude derating factors, and contamination protection requirements. Proper specification of these factors during the selection process prevents operational problems and ensures reliable performance.

Conclusion

High voltage motors operating at 6600 volts provide essential power generation capabilities across diverse industrial sectors. From manufacturing facilities to renewable energy installations, these robust systems deliver reliable performance while optimizing energy efficiency and operational costs. The comprehensive benefits include reduced electrical infrastructure requirements, improved power factor characteristics, and enhanced operational reliability.

Successful implementation requires careful consideration of application requirements, environmental conditions, and long-term operational goals. Partnering with experienced suppliers ensures optimal motor selection and comprehensive support throughout the equipment lifecycle. As industrial automation continues expanding globally, the demand for reliable high voltage motor solutions will continue growing, making proper supplier selection increasingly important for operational success.

Frequently Asked Questions

Q1: What makes 6600V motors suitable for industrial power generation applications?

A: These motors provide excellent power-to-size ratios with reduced current requirements compared to lower voltage alternatives. The higher voltage operation results in smaller conductors, reduced electrical losses, and improved system efficiency, making them ideal for industrial applications requiring reliable, continuous power delivery.

Q2: How do high voltage motors compare to standard motors in terms of energy efficiency?

A: High voltage motors typically achieve superior efficiency ratings due to reduced electrical losses and optimized magnetic circuit designs. The reduced current flow at higher voltages minimizes conductor losses, while advanced cooling systems and premium materials contribute to overall efficiency improvements of 2-5% compared to equivalent lower voltage motors.

Q3: What maintenance requirements should facilities expect with 6600V motor installations?

A: Regular maintenance includes bearing lubrication, insulation testing, vibration monitoring, and thermal analysis. Most installations require quarterly inspections with annual comprehensive testing. Proper maintenance programs typically extend motor life to 20-25 years while maintaining optimal performance characteristics throughout the service period.

Q4: Can existing electrical infrastructure support 6600V motor installations?

A: Infrastructure compatibility depends on existing electrical distribution systems and available transformer capacity. Many facilities require electrical upgrades including medium voltage switchgear, appropriate protection devices, and qualified electrical personnel. A thorough electrical system assessment determines necessary modifications before motor installation.

Q5: What environmental factors affect 6600V motor performance and selection?

A: Key environmental considerations include ambient temperature ranges, humidity levels, altitude, and contamination exposure. Motors require derating at elevations above 3,300 feet or temperatures exceeding 40°C. Specialized enclosures and cooling systems address challenging environmental conditions while maintaining reliable operation.

Get Reliable 6600V Motor Solutions from XCMOTOR

Selecting the right high voltage motor supplier ensures optimal performance and long-term reliability for your industrial applications. XCMOTOR stands out as a trusted 6600v motor manufacturer, offering comprehensive power equipment solutions backed by exceptional customer support and technical expertise.

Our commitment to delivering original products from trusted brands guarantees the quality and performance your operations demand. Every motor undergoes rigorous testing to ensure compliance with international standards and customer specifications. Fast delivery capabilities minimize project delays, while our comprehensive inventory ensures availability when you need it most.

When evaluating motor options for your next project, consider the long-term benefits of partnering with experienced professionals who understand the unique challenges of high voltage applications. Our technical team provides guidance on motor selection, installation requirements, and maintenance best practices to optimize system performance.

Contact us at xcmotors@163.com to discuss your specific requirements and discover how our 6600v motor solutions can enhance your operational efficiency while reducing total cost of ownership.

References

- IEEE Standard 841-2021: Standard for Petroleum and Chemical Industry - Premium Efficiency Severe Duty Totally Enclosed Fan-Cooled (TEFC) Squirrel Cage Induction Motors

- National Electrical Manufacturers Association (NEMA). "Motors and Generators Standards Publication MG 1-2016." Rosslyn, VA: NEMA, 2016

- International Electrotechnical Commission. "IEC 60034-1:2017 Rotating Electrical Machines - Part 1: Rating and Performance." Geneva: IEC, 2017

- Chapman, Stephen J. "Electric Machinery Fundamentals, 5th Edition." New York: McGraw-Hill Education, 2012

- Hughes, Austin, and Bill Drury. "Electric Motors and Drives: Fundamentals, Types and Applications, 4th Edition." Oxford: Newnes, 2013

- Boldea, Ion, and Syed A. Nasar. "Electric Drives, 3rd Edition." Boca Raton: CRC Press, 2016