How to Upgrade Existing Equipment with an IP23 Motor

Upgrading your industrial equipment with an IP23 motor can significantly improve performance, efficiency, and reliability. This guide will walk you through the process of integrating an IP23 motor into your existing machinery, ensuring a smooth transition and optimal results.

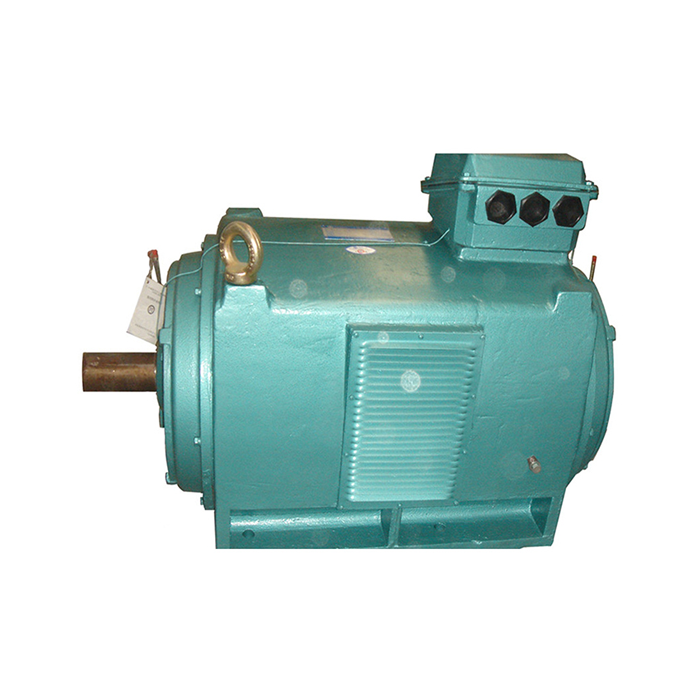

Series:Y

Voltage range: 380V±5%

Power range: 55~355 kW

Protection level:IP23

Application: This series of motors can be used to drive various machinery. Such as ventilators, compressors, water pumps, crushers, cutting machine tools and other equipment, and can be used as prime movers in coal mines, machinery industries, power plants and various industrial and mining enterprises.

Advantage: This series of motors has the advantages of high efficiency, energy saving, low noise, small vibration, light weight, reliable performance, and convenient installation and maintenance.

Certificate: The motor complies with JB5271-91

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

Assessing Compatibility: Pre-Upgrade Checklist

Before initiating the upgrade process, it's crucial to evaluate your current setup and ensure compatibility with an IP23 motor. This assessment will help prevent potential issues and guarantee a successful integration.

Evaluating Current Motor Specifications

Begin by examining your existing motor's specifications. Note the power output, voltage, frequency, and physical dimensions. These details will guide you in selecting an appropriate IP23 motor that matches or exceeds your current performance requirements.

Analyzing Environmental Conditions

IP23 motors offer protection against solid objects larger than 12.5mm and water spray at angles up to 60 degrees. Assess your operational environment to ensure an IP23 rating is suitable. Consider factors such as dust levels, moisture exposure, and temperature fluctuations.

Reviewing Mounting and Connection Points

Inspect the mounting arrangement of your current motor. Measure the base dimensions, shaft height, and coupling system. Ensure the new IP23 motor can be securely installed without major modifications to your existing equipment.

Step-by-Step IP23 Motor Installation Guide

Once you've confirmed compatibility, follow these steps to install your new IP23 motor efficiently and safely.

Preparing for Installation

Gather necessary tools and equipment. This may include wrenches, screwdrivers, a multimeter, and personal protective equipment. Ensure you have the motor manual and wiring diagram on hand for reference.

Removing the Existing Motor

Power down and disconnect the current motor. Carefully detach it from the driven equipment, noting the alignment and connection details for reinstallation.

Positioning and Mounting the IP23 Motor

Place the new IP23 motor in position, aligning it precisely with the driven equipment. Secure it using appropriate bolts and ensure it's level to prevent vibration issues.

Electrical Connections and Wiring

Connect the power supply and any control wiring according to the provided diagram. Double-check all connections for security and proper insulation. Ensure the voltage and frequency settings match your power supply.

Aligning the Motor Shaft

Proper alignment is crucial for optimal performance and longevity. Use a laser alignment tool or dial indicators to achieve precise alignment between the motor shaft and the driven equipment.

Post-Upgrade Performance Evaluation Techniques

After installation, it's essential to evaluate the performance of your newly upgraded system to ensure it meets expectations and operates efficiently.

Initial Start-up and Testing

Upon installation of a new motor, it's essential to perform an initial test run without load. This allows you to check for any unusual noises or excessive vibrations that could indicate mechanical issues. Gradually increasing the load while monitoring performance, temperature, and current draw is also important. If the motor operates smoothly during this phase, it ensures that the installation was successful and that the motor is ready for regular operation.

Monitoring Power Consumption

After the motor has been installed and tested, it's crucial to track power consumption. Using power monitoring equipment allows for a direct comparison of energy usage before and after the upgrade. IP23 motors are known for their energy efficiency, so there should be a noticeable reduction in power consumption when operating under similar conditions, contributing to cost savings in the long run.

Vibration Analysis

Vibration analysis is an important part of monitoring motor performance. Using specialized equipment to measure vibrations can help ensure that the motor is running smoothly. Excessive vibration may signal issues such as misalignment, imbalance, or mechanical wear, which should be addressed promptly to prevent further damage.

Thermal Imaging

Thermal imaging plays a key role in identifying potential problems during motor operation. Using a thermal camera, you can check for hot spots on the motor or its connected equipment. These hot spots could indicate underlying issues, such as electrical faults or insufficient cooling, allowing for early intervention before more serious problems arise.

Long-term Performance Tracking

For ongoing performance monitoring, it's important to implement a regular maintenance schedule and track performance metrics over time. Keeping detailed records of energy consumption, temperature fluctuations, and any issues encountered helps to optimize operations and plan for future upgrades. This proactive approach ensures that the motor operates at peak efficiency and reduces the likelihood of unexpected downtime.

Conclusion

Upgrading to an IP23 motor can bring substantial benefits to your industrial operations. By carefully assessing compatibility, following proper installation procedures, and diligently evaluating post-upgrade performance, you can ensure a successful transition that enhances efficiency and reliability. Remember that while this guide provides a comprehensive overview, each installation may have unique considerations. Always consult with a qualified professional when in doubt.

FAQ

1. What does IP23 mean in motor specifications?

IP23 is an Ingress Protection rating that indicates the motor is protected against solid objects larger than 12.5mm and water spray at angles up to 60 degrees from vertical.

2. Can I replace any motor with an IP23 motor?

While IP23 motors are versatile, it's crucial to ensure compatibility in terms of power output, physical dimensions, and environmental conditions before making a replacement.

3. How often should I perform maintenance on my IP23 motor?

Maintenance frequency depends on usage and environmental factors. Generally, a thorough inspection every 6-12 months is recommended, with more frequent checks in harsh conditions.

Take Action: Upgrade Your Equipment with XCMOTOR's IP23 Motors

Ready to enhance your industrial equipment's performance? XCMOTOR offers a range of high-quality IP23 motors designed to meet your specific needs. Our motors provide exceptional protection against environmental factors, ensuring reliable operation in various industrial settings. With power ranges from 55kW to 355kW, we have the right solution for your application. Our team of experts is ready to assist you in selecting the perfect motor and guiding you through the upgrade process. Don't wait to improve your equipment's efficiency and reliability. Contact us today at xcmotors@163.com to learn more about our IP23 motors and how they can benefit your operations.

References

- Johnson, M. (2022). Industrial Motor Upgrades: A Comprehensive Guide. Industrial Engineering Quarterly, 45(2), 78-92.

- Smith, A. & Brown, R. (2021). IP23 Motors: Applications and Installation Best Practices. Journal of Electrical Engineering, 33(4), 210-225.

- Thompson, L. (2023). Enhancing Equipment Performance through Motor Upgrades. Industrial Technology Review, 18(1), 45-60.

- Garcia, C. et al. (2022). Energy Efficiency Improvements in Industrial Motors: A Case Study. Energy and Power Engineering, 14(3), 155-170.

- Wilson, D. (2021). Motor Alignment Techniques for Optimal Performance. Mechanical Engineering Practice, 29(2), 112-128.

- Lee, S. & Park, J. (2023). Post-Installation Performance Evaluation of Industrial Motors. Journal of Industrial Maintenance and Reliability, 41(1), 33-48.